Basic info of 4×8 Aluminum Sheets

4×8 aluminum sheets are 4 feet by 8 feet in size. In other words, it measures 48inches broad by 96inches long. The “4×8” size is commonly used and widely available in the aluminum industry for a variety of applications.

Aluminum sheets are flat pieces of aluminum that are frequently used in manufacturing, building, and other industries because of their strong, lightweight, and resistance to corrosion qualities. They are available in several thicknesses, and the 4×8 size is a typical size that makes handling and transit easier.

Different aluminum alloys, such as 3003 aluminum, 5052 aluminum, or 6061 aluminum, each having their own unique properties and uses, can be used to create the 4×8 aluminum sheet. It can be applied to many different things, including as storage tanks, trailer cladding, car panels, signage, and building facades. Many sectors choose aluminum because of its strength and adaptability.

Advantages of 4×8 aluminum sheets

- Lightweight and Easy to Transport: Aluminum is a lightweight material, making 4×8 aluminum sheets easy to handle and transport. This characteristic is particularly beneficial for construction projects, where large quantities of materials need to be transported to the site. The lightweight nature of aluminum also reduces the load on structures, making it an ideal choice for applications where weight is a critical factor.

- Corrosion Resistance and Durability: Aluminum has a natural oxide layer that forms on its surface, providing excellent corrosion resistance. This resistance to corrosion makes 4×8 aluminum sheets suitable for outdoor applications where they are exposed to harsh weather conditions, moisture, and UV rays. Unlike other metals, aluminum does not rust, ensuring a longer lifespan and lower maintenance requirements.

- Excellent Strength-to-Weight Ratio: Aluminum boasts a high strength-to-weight ratio, making it stronger than many other materials while still being lightweight. This characteristic allows 4×8 aluminum sheets to provide structural strength and integrity without adding excessive weight to the overall structure. It is particularly advantageous in applications such as aerospace, automotive, and transportation industries, where weight reduction is crucial for fuel efficiency and performance.

- Versatility in Fabrication and Customization: 4×8 aluminum sheets offer excellent versatility in terms of fabrication and customization. Aluminum is highly malleable and can be easily formed, cut, bent, and welded to meet specific design requirements. This versatility allows for the creation of complex shapes, profiles, and customized components, making it suitable for various applications across different industries.

- Recyclability and Environmental Sustainability: Aluminum is a highly recyclable material, and 4×8 aluminum sheets can be recycled repeatedly without losing their inherent properties. Recycling aluminum requires significantly less energy compared to primary production, making it an environmentally sustainable choice. The recyclability of aluminum contributes to reducing waste and conserving natural resources, making it an eco-friendly material option.

- Thermal and Electrical Conductivity: Aluminum is an excellent conductor of heat and electricity. In applications where heat dissipation or electrical conductivity is crucial, such as electrical enclosures or heat sinks, 4×8 aluminum sheets provide efficient performance. The high thermal conductivity of aluminum helps dissipate heat quickly, while its electrical conductivity allows for effective transmission of electricity.

The advantages above make 4×8 aluminum sheets suitable for a wide array of applications in industries such as construction, automotive, manufacturing, signage, recreation, and more.

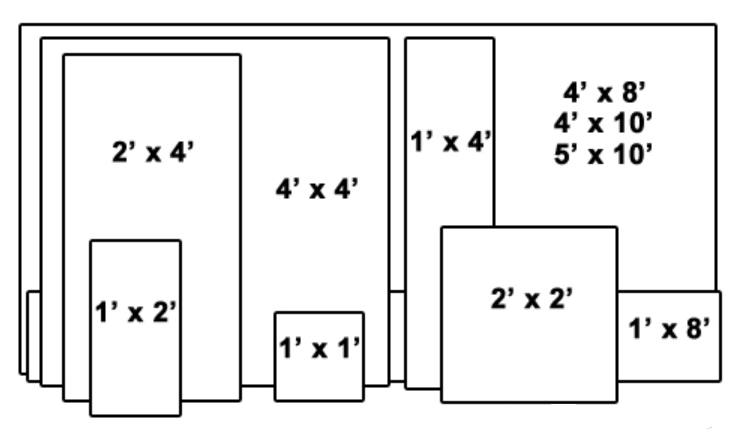

Standard aluminum sheet sizes

For aluminum sheets, the following standard sheets sizes are most frequently used:

3×8 Aluminum sheets: These sheets can be used in a variety of ways, including exhibitions, architecture, and signs. The specified thickness and alloy type will determine their unique application.

4×8 Aluminum sheets are very common and used extensively in signage, building, and other fabrication projects. It provides a nice mix of material availability, handling ease, and versatility.

4×10 Aluminum sheets are slightly bigger than typical sheets measuring 4×8, these sizes are frequently chosen for covering larger areas or when a lower joint count is desired. They are frequently utilized for cladding, roofing, and architectural purposes.

5×10 Aluminum sheets: These sheets work well for larger panels, such those used in truck trailers, RV bodies, and marine applications because of their increased surface area.

Common applications for 4×8 aluminum sheets

4×8 aluminum sheets, with dimensions of 4 feet by 8 feet, are commonly used in various applications due to their convenient size and versatility. Here are some common applications for 4×8 aluminum sheets:

1. Construction and Architecture: 4×8 aluminum sheets are frequently utilized in the construction industry for applications such as wall cladding, roofing, facias, and decorative elements. They offer durability, weather resistance, and ease of installation.

2. Signage and Displays: 4×8 aluminum sheets of this size are popular for creating signs, including outdoor signage, shop fronts, and advertising boards. They provide a lightweight, rigid, and corrosion-resistant material for displaying information and graphics.

3. General Fabrication: 4×8 aluminum sheets are widely used in general fabrication projects. They serve as a versatile material for fabricating various components, such as brackets, panels, covers, and enclosures. The sheets can be easily cut, bent, and formed to meet specific design requirements.

4. Transportation: 4×8 aluminum sheets find applications in the transportation industry, particularly for manufacturing truck bodies, trailer panels, and cargo containers. The lightweight nature of aluminum helps reduce vehicle weight, leading to improved fuel efficiency and increased payload capacity.

5. Marine and Boating: Due to its corrosion resistance, aluminum is commonly used in marine applications. 4×8 aluminum sheets are utilized in boat building, including hulls, decks, bulkheads, and other structural components. Aluminum’s lightweight and high strength-to-weight ratio make it ideal for marine environments.

6. Automotive: 4×8 aluminum sheets are used in the automotive sector for a variety of reasons, including the production of body panels, interior trim, and structural components.

7. HVAC and ducting: 4×8 aluminum sheets can be used to make ducting and HVAC (Heating, Ventilation, and Air Conditioning) systems. Aluminum’s corrosion resistance and thermal conductivity make it an excellent choice for these applications.

8. DIY & Home renovation: 4×8 aluminum sheets of this size are frequently utilized by do-it-yourselfers and home renovation enthusiasts. They can be used for backsplashes, countertops, wall coverings, and custom furniture.

9. Food and beverage packaging sector: Because of their sanitary characteristics and corrosion resistance, 4×8 aluminum sheets are frequently utilized in the food and beverage packaging sectors.

10. Aerospace: 4×8 aluminum sheets play a crucial role in the aerospace industry. They are used for manufacturing aircraft structures, wings, fuselage panels, and interior components. The combination of aluminum’s lightweight nature and strength makes it an ideal material for aircraft applications.

11. Electrical and Electronics: 4×8 aluminum sheets find applications in the electrical and electronics industry. They are used for manufacturing electrical enclosures, heat sinks, and components for electronic devices. Aluminum’s excellent thermal conductivity helps dissipate heat effectively.

12. Industrial Equipment and Machinery: 4×8 aluminum sheets are employed in the manufacturing of industrial equipment and machinery. They are used for fabricating machine frames, support structures, covers, and guarding. Aluminum’s strength and durability make it suitable for demanding industrial environments.

13. Art and Design: 4×8 aluminum sheets are popular among artists and designers due to their aesthetic appeal and flexibility. They can be used for creating sculptures, architectural installations, decorative panels, and custom furniture pieces. Aluminum’s ability to be easily cut, shaped, and finished allows for artistic creativity.

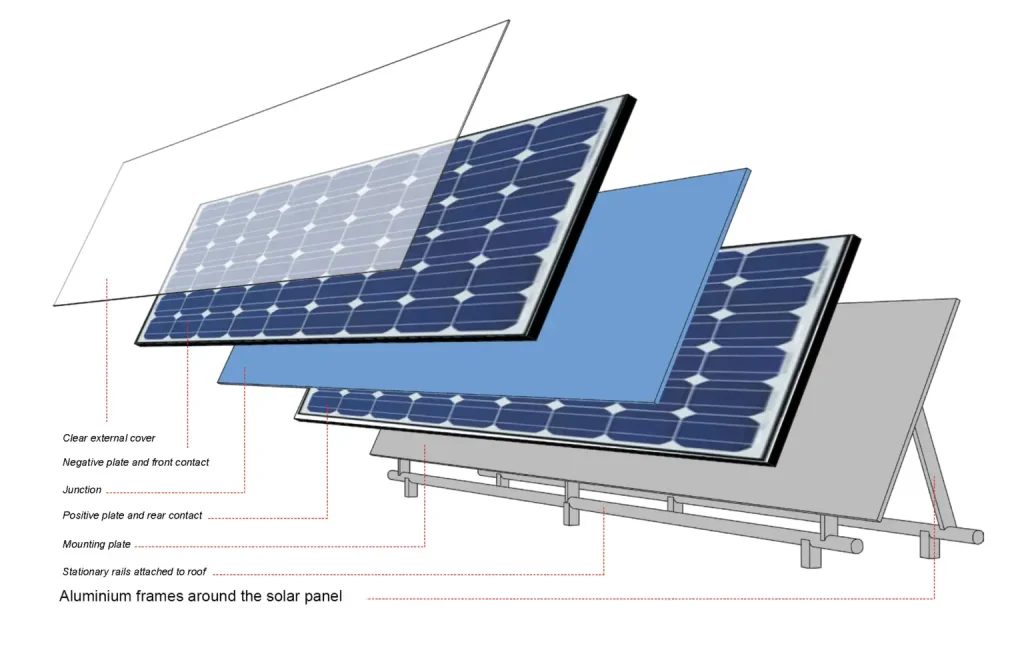

14. Energy and Renewable Resources: 4×8 aluminum sheets are utilized in the energy sector for various applications. They are used in solar panel frames, wind turbine components, and electrical transmission systems. Aluminum’s lightweight and corrosion resistance make it well-suited for renewable energy applications.

15. Sporting Goods: 4×8 aluminum sheets are employed in the manufacturing of sporting goods, such as bicycle frames, golf club heads, and athletic equipment. Aluminum’s strength, lightness, and durability contribute to enhanced performance and efficiency in sports equipment.

16. Retail and Display: 4×8 aluminum sheets find applications in the retail and display industry. They are used for creating store fixtures, shelving, trade show booths, and product displays. Aluminum’s versatility and aesthetic appeal make it a preferred choice for showcasing products.

17. Medical and Healthcare: 4×8 aluminum sheets have applications in the medical and healthcare sectors. They are used for manufacturing equipment and devices, such as medical carts, beds, patient lifts, and diagnostic machines. Aluminum’s cleanliness, durability, and non-reactivity with sterilization processes make it suitable for medical environments.

4×8 aluminum sheets are widely used across various industries. The versatility, lightweight nature, corrosion resistance, and ease of fabrication make aluminum sheets a popular choice for numerous projects and applications.

Different Series of aluminum sheets

Aluminum sheets are often classified into different series based on their alloy composition. Each series has its unique properties and applications. Here are the commonly recognized series of aluminum sheets:

1000 Series Aluminum: This series comprises commercially pure aluminum, with a minimum aluminum content of 99%. It is known for its excellent corrosion resistance and high electrical conductivity. The 1xxx series is typically used for applications that require good formability and conductivity, such as electrical conductors, heat exchangers, and chemical equipment.

2000 Series Aluminum: This series is alloyed with copper and typically contains small amounts of other elements like manganese and magnesium. It offers good strength and heat resistance. The 2xxx series is commonly used in aerospace applications and structural components where high strength is required.

3000 Series Aluminum: This series is alloyed with manganese, which provides improved strength and corrosion resistance. It is known for its excellent formability and weldability. The 3xxx series finds applications in general sheet metal work, including cooking utensils, chemical equipment, and packaging.

4000 Series Aluminum: This series contains silicon as its primary alloying element. It has good fluidity during casting and is often used in welding applications. The 4xxx series is commonly used for filler materials and welding wires.

5000 Series Aluminum: This series is alloyed primarily with magnesium. It offers excellent corrosion resistance, high strength, and good formability. The 5xxx series is widely used in automotive components, transportation equipment, and marine applications.

6000 Series Aluminum: This series is alloyed with magnesium and silicon, providing a combination of strength, formability, and corrosion resistance. The 6xxx series, particularly alloy 6061, is one of the most versatile and commonly used aluminum alloys. It finds applications in structural components, automotive parts, and aerospace equipment.

7000 Series Aluminum: This series is alloyed primarily with zinc, with small additions of copper, magnesium, and chromium. It offers excellent strength and is commonly used in aerospace applications and high-stress structural components.

8000 Series Aluminum: This series is alloyed primarily with lithium, offering exceptional strength and low density. The 8xxx series is mainly used in aerospace applications where weight reduction is critical.

It’s important to note that there are other specialized series and subseries of aluminum alloys beyond the ones listed here, each with its own specific properties and applications. The selection of the appropriate series depends on the requirements of the desired application, such as strength, corrosion resistance, formability, and weldability.

What should be paid attention to when purchasing aluminum sheets?

It is crucial to take your project s particular needs into account when buying a 4×8 aluminum sheets, including the preferred alloy, thickness, and finish. Depending on the intended use, aluminum sheets can be acquired from hardware stores, metal suppliers, or internet vendors. They are usually available in a range of thicknesses, from thinner gauge sheets to heavier plates.

When purchasing aluminum sheets, there are several factors to consider and pay attention to in order to ensure you select the right product for your specific needs. Here are some important points to consider:

1. Alloy and Grade: Determine the alloy and grade of aluminum sheet that best suits your intended application. Different alloys offer varying properties such as strength, corrosion resistance, formability, and weldability. Choose the alloy and grade that aligns with your project requirements.

2. Thickness: Consider the required thickness of the aluminum sheet. Thicker sheets provide greater strength but may be less formable. Thinner sheets are more flexible but may have lower strength. Select the appropriate thickness based on the structural and functional demands of your project.

3. Size and Dimensions: Determine the required size and dimensions of the aluminum sheet. Consider factors like length, width, and thickness to ensure it fits your intended application. Common sheet sizes include 4×8 feet, 4×10 feet, and 5×10 feet. Additionally, check if the sheet needs to be cut or trimmed to meet your specific requirements.

4. Surface Finish: Aluminum sheets are available in various surface finishes, such as mill finish (raw), brushed, painted, or anodized aluminum sheets. The surface finish can impact the appearance, corrosion resistance, and functional properties of the sheet. Choose the appropriate finish based on your aesthetic preferences and functional needs.

5. Quality and Certification: Ensure that the aluminum sheets you purchase meet the required quality standards and certifications. Look for reputable suppliers and manufacturers who adhere to industry standards and provide certifications for their products, such as ASTM (American Society for Testing and Materials) or ISO (International Organization for Standardization) certifications.

6. Supplier Reputation: Research the reputation and reliability of the supplier or manufacturer from whom you plan to purchase the aluminum sheets. Check customer reviews, testimonials, and their track record in delivering quality products on time.

7. Price and Value: Compare prices from different suppliers to ensure a fair and competitive price. However, prioritize value over the lowest price alone. Consider factors such as quality, service, and product support in addition to the price to ensure you get the best overall value for your investment.

8. Quantity and Lead Time: Determine the required quantity of aluminum sheets and confirm the supplier’s ability to fulfill your order within the desired timeframe. Ensure they have sufficient stock or production capacity to meet your needs.

By paying attention to these factors, you can make an informed decision when purchasing aluminum sheets that will meet your requirements.

Overall, 4×8 aluminum sheets are standard size aluminum sheets that offers versatility and convenience for different projects, providing a durable and lightweight material for a wide range of applications.