What Is 8011 Material?

8011 aluminum foil is a commonly used aluminum alloy material and belongs to the 8000 series alloy. Its main alloying elements are iron and silicon, which have the characteristics of high temperature resistance, strong adhesion and excellent barrier properties. The common thickness is 0.006-0.2mm. As one of our company’s best-selling products, Yongsheng 8011 aluminum foil has a clean surface, uniform quality, no oil stains, and no pinholes. It is commonly used in food packaging, medicinal aluminum foil, milk cap foil, cable foil, aluminum candle holders, sealing foil, etc. production material. This article will comprehensively provide you with the broad market applications of 8011 aluminum foil:

Properties Of 8011 Aluminum Foil:

1. High-strength heat-treatable alloy with good heat resistance.

2. Good fatigue resistance and stress corrosion cracking resistance.

3. Good stiffness and specific strength.

4. Good machinability.

8011 Aluminum Foil Production Process:

1. Melting : The ingot is heated in a furnace to a temperature of around 730-760°C until it melts.

2.Casting : Once the aluminium has melted, it is cast into large slabs. The slabs are then rolled into thinner sheets for the production of the final product.

3.Rolling: Aluminium sheets are rolled through a rolling mill to reduce their thickness and improve their uniformity.

4.Annealing: It involves heating the aluminium foil to a specific temperature and then cooling it slowly.

5.Processing: After annealing, the aluminium foil is trimmed to the required width and cut into rolls, which can be plain or coated with a thin layer of protective material.

6.Quality control: Measurement of the foil’s thickness, tensile strength, elongation, surface quality, etc..

What Is The Composition of Al8011?

The surface of 8011 aluminum foil is clean, uniform in color, no spots, and no holes. Its main chemical components include aluminum, iron, silicon, manganese and magnesium. The following are the main chemical components of 8011:

| Al | Si | Cu | Mg | Zn | Mn | Cr | Fe | Ti | Other | Other (Total) |

| Remainder | 0.50-0.90 | ≤0.1 | ≤0.05 | ≤0.1 | ≤0.2 | ≤0.05 | 0.60-1.0 | ≤0.08 | ≤0.05 | ≤0.15 |

8011 Aluminium Foil’s Wide Range Of Applications:

Bottle cap packaging:

8011 aluminium foil has good sealing properties and is compatible with and provides protection for a wide range of cap systems, including screw caps, crown caps, ROPP caps and other types of caps used in the beverage and pharmaceutical industries. Other alloys such as 3105 aluminium foil can also withstand high mechanical stress and are also suitable for bottle cap packaging. Yongsheng 8011 aluminium foil is usually used as white wine bottle caps, red wine bottle caps, cosmetic bottle caps, milk powder bottle caps, pharmaceutical bottle caps, beverage bottle caps, yoghurt bottle caps and so on. Its advantages are: food grade, drawing grade A.

Pharmaceutical packaging:

8011 aluminum foil and 8021 aluminum foil are high quality aluminum alloys that meet the requirements of the pharmaceutical industry. They insulate oxygen, light and moisture, effectively preventing pharmaceuticals from coming into contact with the outside air. They are widely used in blister packaging and cold forming packaging for tablets, capsules and pills. Yongsheng pharmaceutical aluminum foils have the advantages of high cupping value, high heat sealing strength, no pinholes and good sealing performance.

Most customers buy 8011-O foil and 8011-H18 foil for PTP drug packaging, cold press molding, pharmaceutical packaging, capsule foil and so on. In addition, 8011-H14 and 8011-H16 can be used to make wine caps, easy-open caps, medical bottle caps, and easy-tear milk powder caps. Most of the medical bottle caps are made of 8011-H16 aluminum foil, which is widely used for oral liquid. The same series of 8021 O and 8079 O aluminum foils with a thickness of 0.045 mm can also be used for tropical blister packaging, which is a popular purchase for pharmaceutical packaging production.

Sealing aluminum foil:

8011 aluminum foil is commonly used for sealing aluminium foil. The construction of sealing aluminum foil includes a heat sealing layer, aluminum foil, a weak adhesive layer, cardboard elastomer, and other components. It is mostly utilized in food, medicine, cosmetics, oil, detergent, hair care products, alcohol sealing gaskets, and so on. It has anti-leakage, freshness preservation, anti-deterioration, anti-counterfeiting, anti-theft, moisture-proof properties, and so on.

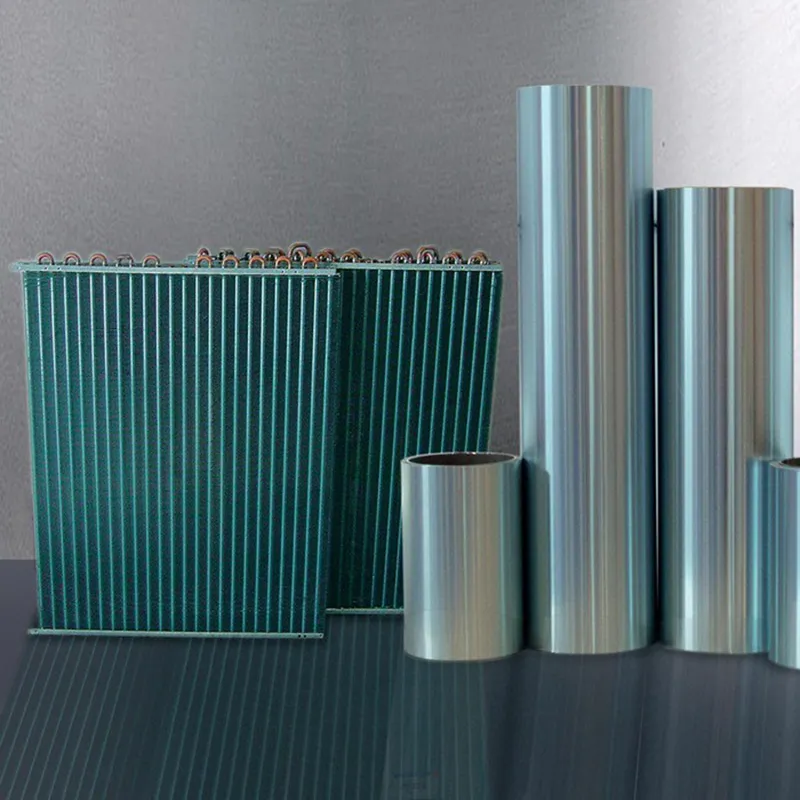

Air conditioning aluminum foil:

8011 aluminum foil has better performance than pure aluminum foil and is used in air conditioning heat exchangers. Its application in refrigeration equipment is also becoming more and more common, and can be used in condensers, coolers, evaporators, radiators, heat exchangers, fin evaporators, fin condensers, evaporator equipment, etc.

Insulating aluminum foil:

8011 aluminum foil has excellent moisture-proof properties, light-shielding properties and barrier capabilities. When laying floor heating pipes on the ground, a layer of aluminum foil can be laid above the pipes as an insulation layer, which can effectively reduce ground heat loss and enhance the sound insulation effect of floor heating.

Hookah foil:

Hookah foil is made from food-grade aluminum foil, which is commonly 8011 alloy. It can efficiently ensure the quality and safety of tobacco products, as well as fully utilize its sealing performance to prevent dangerous compounds from volatilizing.

Aluminum foil sealing film:

Sealing films, like the yogurt and medicine bottle sealing films, are typically found at the sealing areas of containers. Among the most common types of sealing aluminum foil are 1235, 8011, 8079, and so on. The following are the specifications:

| Alloy | Temper | Thickness (mm) | Width (mm) | Length (mm) | Typical Applications |

| 1235, 8011, 8079 | O, H18 | 0.016-0.2 | 100-1700 | Any | Pressure-sensitive aluminum foil gaskets, half-pull aluminum foil gaskets, sealing gaskets, etc. |

For example, yogurt sealing films are mostly aluminum foil composite film materials, mainly composed of three materials: polyester, aluminum foil, and hot air layer. The raw materials of yogurt sealing films aluminum foil are mainly 8xxx series alloys, such as 8011 aluminum foil and 8079 aluminum foil.

Aluminum foil lunch boxes:

Aluminum foil lunch boxes are divided into wrinkle-free lunch boxes and wrinkled lunch boxes, mainly using 3000 series aluminum foil and 8000 series aluminum foil as raw materials. The most commonly used ones are 3003 aluminum foil, 8011 aluminum foil, and 8006 aluminum foil. Among them, 8006 aluminum foil is mostly used to make wrinkle-free lunch boxes. It has the advantages of smooth surface, no pinholes, no dust particles, no odor, safe and hygienic, and high elongation rate. Our factory also produces aluminum foil for various aluminum lunch boxes at home and abroad.

Aluminum foil tape:

8011-O and 8011-H18 aluminium foil are the starting materials used to make aluminium foil tape. Numerous benefits of Yongsheng’s aluminum foil tape base material include clean oil removal, fewer pinholes, superior product shape, resistance to deformation when cut, and difficulty degumming.

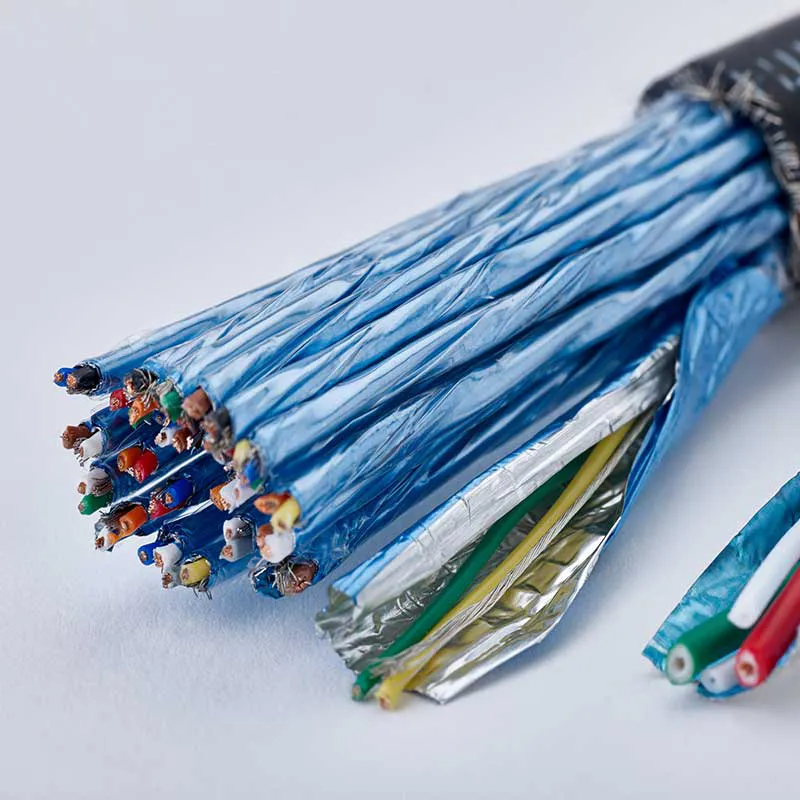

Aluminum foil strip for cables:

Aluminum foil for cables acts as a shielding material to safeguard cables. Cable aluminum strip alloys that are commonly used include: 1050, 1060, 1100, 1235, 8011, and others

Aluminium foil cup candle:

The raw material of aluminum candle box/aluminium foil cup candle is high elongation 8011 aluminum foil or 3105 aluminum alloy, which has a simple appearance and fine production. Compared with plastic candle boxes, aluminum candle boxes are not only superior in performance, but can also be mechanized and large-scale in production. They are also low-cost, pollution-free, and can be recycled.

Advantages Of Yongsheng 8011 Aluminum Foil:

- Brush water grade A, clean surface, uniform colour, no spot, smooth and no pinhole.

- Excellent moisture-proof performance, shading performance and high barrier capacity, strong mechanical properties, anti-explosion, puncture, tearing performance.

- Non-toxic, odourless, safe and hygienic.

- Composite, printing, coated aluminium foil is widely used as packaging materials.

YSA 8011 aluminum foil packaging: Export-grade, wrapped in plastic film and collision cotton, and placed into wooden boxes. It has adequate strength and appropriate protection for maritime transit. A package’s weight is typically 1 ton.