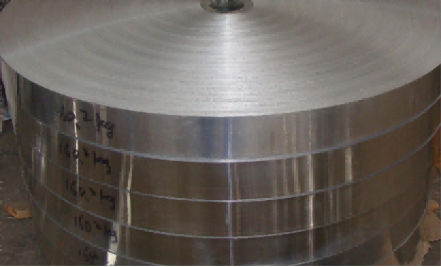

1060 aluminum strip is a high-purity aluminum alloy material, comprising at least 99.6% aluminum. Its outstanding physical and chemical properties make it an excellent choice in various industries and applications. In the context of rapid advancements in materials science, 1060 aluminum strip has become an indispensable material due to its superior performance and cost-effectiveness. This article will explore the characteristics, advantages, and main application areas of 1060 aluminum strip, helping you better understand the significance of this material.

1. Characteristics

The characteristics of 1060 aluminum strip make it especially effective across numerous fields. Key features include:

– High Conductivity

The electrical conductivity of 1060 aluminum strip exceeds 61% IACS (International Annealed Copper Standard), making it an ideal material for electrical and electronic products. This capability makes it suitable for wires, cables, and electrical connectors, providing stable and efficient conductivity for various electrical connections.

– Excellent Formability

1060 aluminum strip exhibits superior workability, allowing for easy stamping, bending, and welding. This property gives designers and engineers greater flexibility to create complex structures and shapes to meet specific functional needs.

High-purity aluminum has strong oxidation and corrosion resistance. This means that 1060 aluminum tape can maintain its physical properties and appearance even in humid or chemically corrosive environments. This characteristic is particularly suitable for industries such as marine and chemical processing, helping extend product lifespans.

– Lightweight

The low density of aluminum significantly reduces overall packaging weight. This not only lowers transportation costs but also simplifies installation processes, especially in industries that require high strength while being lightweight, thus maintaining a strong competitive edge.

2. Advantages of 1060 Aluminum Strip

The advantages of 1060 aluminum strip are extensive, which has led to its widespread popularity on the market. Here are its main benefits:

– Cost-Effectiveness

The production costs of 1060 aluminum tape are relatively low, making it suitable for large-scale manufacturing. Due to the availability of raw materials and mature production processes, 1060 aluminum strip can meet quality requirements while lowering overall operational costs, thereby creating higher profit margins for businesses.

– Environmental Friendliness

Aluminum is highly recyclable, and the use of 1060 aluminum strip promotes sustainable packaging practices, appealing to environmentally conscious consumers and brands.

– Aesthetic Appeal

The smooth surface of 1060 aluminum strip, along with its good post-processing capabilities, makes it easy to undergo various surface treatments, such as anodizing, polishing, and coating. This allows products to not only be functional but also visually appealing, suitable for applications requiring aesthetic considerations.

3. Application Areas

1060 aluminum tape is widely applied across multiple industries due to its exceptional performance, including:

– Electrical and Electronics Industries

Its excellent conductivity makes 1060 aluminum strip critical in the manufacturing of electrical and electronic products. Common applications include cables, connectors, and internal components of appliances, enhancing the reliability of electrical devices and meeting high-performance market demands.

– Construction Industry

In the construction sector, 1060 aluminum strip is used for windows, doors, curtain walls, and roofing materials. Its corrosion resistance and aesthetic qualities make it popular in modern architectural designs, adding a stylish element while ensuring long-term performance.

– Transportation

In the transportation sector, 1060 aluminum strip is widely used for interior and exterior components of vehicles, such as panels, dashboards, and body parts. Its lightweight and high-strength properties help reduce vehicle weight, improve fuel efficiency, and lower transportation costs.

– Home Appliances

In the home appliance industry, 1060 aluminum tape is used in the internal structure and casing of refrigerators, washing machines, and more. Its corrosion resistance and good thermal conductivity enhance the efficiency and safety of home appliances.

– Packaging Industry

Thanks to its excellent barrier properties, 1060 aluminum tape is also widely used in the production of aluminum foil and other packaging materials. Whether for food or pharmaceutical packaging, 1060 aluminum strip effectively protects product quality and extends shelf life.

4. Future Development Trends

With ongoing technological advancements and changing industry demands, the market prospects for 1060 aluminum strip are very promising. Future developments will likely focus on the following areas:

– Technological Innovations

The manufacturing processes for 1060 aluminum strip will become more advanced, potentially incorporating more automation and smart technologies to enhance production efficiency and reduce energy consumption.

– Sustainability Initiatives

As consumers become increasingly aware of environmental issues, the use of 1060 aluminum tape in green building and renewable material sectors will expand. Companies will prioritize minimizing environmental impacts during production to enhance brand image and competitiveness.

– Emerging Markets

With a growing global demand for eco-friendly and efficient materials, 1060 aluminum strip will find applications in new areas, including renewable energy and smart home technologies.

Conclusion

In summary, 1060 aluminum strip stands out for its high conductivity, excellent formability, and corrosion resistance, making it an essential material in various applications. Whether in electrical and electronic, construction, transportation, or packaging sectors, its widespread use highlights its superior performance and cost-effectiveness. As market demands change and technology advances, the application prospects for 1060 aluminum strip will broaden, providing innovative solutions to increasingly diverse industry needs.