Oxidized aluminum is a phenomenon in which aluminum reacts with oxygen in the air to oxidize. Oxidation is a natural process caused by exposure to the elements that causes aluminum surfaces to dull, discolor and pit. This oxide layer acts as a protective barrier, but if left untreated, it can become thick and unsightly. Cleaning oxidized aluminum metal products is critical to maintaining their appearance and preventing further deterioration.

There are many factors that can cause oxidation of aluminum alloys, such as exposure to moisture, pollutants, and harsh environments. Oxidation of aluminum surfaces can be exacerbated if incorrect cleaning and maintenance practices are followed. Oxidation not only reduces the visual appeal of aluminum products but can also compromise its structural integrity over time. Cleaning oxidized aluminum helps restore its original shine and prevent further damage.

For aluminum metal product manufacturers, they usually control the temperature and humidity of the packaging box. The storage environment of the aluminum sheets plates should be dry, bright, well-ventilated, and non-corrosive. The humidity of wooden shafts and box boards should not be greater than 18%. The temperature of packaging aluminum coils shall not exceed 45°C. If it is transported from a low-temperature area to an area with high temperature and humidity, do not open the sealed package immediately. It is necessary to allow aluminum alloy products time to adapt to these environments, and at the same time avoid placing aluminum coils, aluminum plates and other deeply processed products in workshops, warehouses, roofs, leaking rain, snow and other places with high moisture. Factory areas must strengthen air drying management to ensure there is no water in product packaging. Strengthen the management of oil production for customized sizes of rolled aluminum profiles, and control the moisture content below 0.04%. The temperature of packaging color aluminum coils should not exceed 45°C. The packaging of aluminum foil rolls should be sealed and an appropriate amount of desiccant should be placed in each roll. Always note: During storage, contact with chemical materials and moist substances is strictly prohibited. Below I will explain to you how to evaluate the oxidation level of aluminum oxide and how to clean it:

Assessing Aluminum Oxidation Levels

First, carefully inspect the aluminum surface for dullness, discoloration, and rough texture to determine if it is a sign of oxidation. If it is determined that oxidation has occurred, immediately evaluate the degree of oxidation by observing the depth of discoloration and the presence of pitting or corrosion. Pay attention to specific areas that are heavily oxidized or require special attention, such as intricate details or hard-to-reach spots.

Oxidized Aluminum Cleaning Process

A. Gather necessary materials and tools

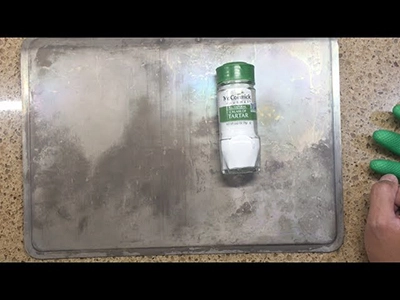

Gather the following items for the cleaning process: vinegar, baking soda, lemon juice, tartar paste, commercial aluminum cleaner, sandpaper (various grit sizes), aluminum polishing product, protective gloves, soft-bristle brush or sponge, microfiber cloth, water source and spray bottles.

B. Ensure safety measures are in place

Before you begin, make sure the cleaning area is well ventilated. If using commercial cleaners or abrasive materials, wear protective gloves and goggles to prevent skin and eye irritation.

C. Pre-cleaning steps to facilitate the process

Wipe gently with a soft cloth or brush to remove any loose dirt or debris from the aluminum surface. This will prevent the surface from being scratched during the cleaning process.

Cleaning Methods Of Oxidized Aluminum

Method 1: Use vinegar and baking soda

Make a cleaning solution using vinegar and baking soda:

Mix equal parts vinegar and baking soda to form a paste consistency. The mild acidity of the vinegar helps dissolve the oxide layer, while the baking soda acts as a mild abrasive.

Apply the solution to the oxidized aluminum surface:

Using a soft-bristled brush or sponge, apply the vinegar and baking soda paste to the affected area. Work in small, circular motions to ensure even coverage.

Gently scrub and rinse away residue:

Gently scrub the oxidized surface with a brush or sponge, paying special attention to stubborn areas. Rinse the aluminum thoroughly with water, making sure to remove all residue.

Method 2: Lemon juice and cream of tartar

Prepare the paste from lemon juice and cream of tartar:

Mix lemon juice and cream of tartar to make a thick paste. Lemon juice contains citric acid, which helps break down oxidation, while cream of tartar is mildly abrasive.

Apply the paste to the affected area:

Using a clean cloth or sponge, apply lemon juice and cream of tartar to the aluminum oxide. Make sure to apply evenly, focusing on heavily oxidized areas. Let the paste sit and then rinse off. Allow the paste to sit on the aluminum surface for approximately 10-15 minutes. This allows the acidic properties to penetrate the oxidation. Then, rinse the aluminum thoroughly with water to remove all traces of paste.

Method 3: Commercial aluminum cleaner

Choosing the Right Commercial Aluminum Cleaner:

Choose a commercial aluminum cleaner designed to remove oxidation. Read the instructions and make sure it’s compatible with the type of aluminum you want to clean.

Follow manufacturer’s instructions for use:

Use commercial cleaners according to the manufacturer’s instructions. Note that the cleaner is sprayed into the oxidized area and penetrates for the specified time.

Rinse the cleaner and evaluate the results:

Rinse the aluminum surface thoroughly with water to remove the cleaner. Evaluate the results and repeat the process if necessary to achieve the desired level of cleanliness.

Deep Cleaning For Stubborn Oxidation Aluminum

Method 1: Wet grinding

Choose the right sandpaper grit for wet sanding: Choose fine-grit sandpaper, such as 2000-grit or higher, to avoid excessive scratching. Wet sanding helps lubricate the surface and prevent sandpaper clogging.

Wet the surface and lubricate it with sandpaper: Use a spray bottle to moisten the aluminum surface with water. Also wet the sandpaper to create a lubricating slurry.

Sand the oxidized area: Apply gentle pressure and sand the oxidized area in smooth, circular motions. Keep the surface and sandpaper moist throughout the process to avoid heat build-up and surface damage. Rinse the aluminum frequently to remove any debris.

Method 2: Choose high-quality aluminum bright products for aluminum bright products

Choose a reputable aluminum brightening product that is specially formulated to eliminate oxidation and restore shine; read and follow the instructions provided by the manufacturer, and use the product according to the instructions. Use a brush or sponge to apply the aluminum brightening product to the affected area. area; make sure to apply an even layer and strictly follow the placement time; finally, rinse the aluminum surface thoroughly with water to remove the shiny product. Evaluate the results of aluminum oxide removal and repeat the process if necessary to achieve the desired brightness and recovery levels.

Method 3: Electrolysis

Prepare electrolyte solution:

Prepare an electrolyte solution by dissolving a small amount of washing soda or baking soda in warm water. Make sure the solution is thoroughly mixed.

Setting up a small electrolytic system for aluminum cleaning:

The oxidized aluminum product is placed in a container containing an electrolyte solution. Connect a sacrificial piece of aluminum (such as aluminum foil) to the positive terminal of the battery charger. Dip the sacrificial aluminum into the electrolyte solution, making sure it does not come into contact with oxidized items.

Soak the aluminum oxide and perform the electrolysis process:

Dip the aluminum oxide into the electrolyte solution, making sure it does not come into contact with the sacrificial aluminum. Connect the negative terminal of the battery charger to the aluminum oxide. Turn on the charger and let the electrolysis process run for a specific amount of time, usually a few hours. Monitor the process and adjust charger settings as needed.

How To Avoid Oxidation Of Aluminum Products?

Regular cleaning and maintenance

Establish a regular cleaning schedule for aluminum products to prevent oxidation buildup. Wipe the surface with a soft cloth and mild detergent to remove dirt and contaminants.

Protective coating on aluminum surfaces

Consider applying a protective coating, such as wax or clear sealant, to the aluminum surface. These coatings act as a barrier against oxidation, UV rays, and UV rays. environmental pollutants.

Proper storage and handling of aluminum products

Store aluminum items in a clean, dry environment away from excessive moisture. Avoid contact with corrosive substances and handle aluminum with clean hands to prevent contamination.

Tips For Safe And Effective Cleaning:

Use appropriate protective equipment: When working with cleaning materials or abrasive substances, wear protective gloves and goggles to protect yourself from potential irritation and injury.

Test cleaning methods on a small area: Before applying any cleaning method to the entire aluminum surface, test it on a small, inconspicuous area. This allows you to evaluate the effectiveness of the method and ensure that it does not cause any damage or adverse reactions.

Avoid using harsh abrasives or chemicals that can damage aluminum: Avoid using harsh abrasives, such as steel wool or abrasive cleaners, as they can scratch and damage aluminum surfaces. Likewise, avoid using strong chemicals or acids that can corrode or etch metal.

How To Maintain Aluminum Products?

A. Thoroughly dry the cleaned aluminum material

After cleaning, make sure the aluminum surface is completely dry to prevent water spots or further oxidation. Use a clean, lint-free cloth or allow to air dry.

B. Use protective sealant or wax

To further protect aluminum and extend its life, consider using a suitable sealant or wax. Follow the manufacturer’s application instructions to ensure an even and thin coat.

C. Develop a maintenance plan for long-term storage

Incorporate your aluminum products into a regular maintenance routine to keep them clean and looking good. Check regularly for signs of oxidation and address any issues that arise promptly.

Cleaning aluminum oxide is a critical step in maintaining its appearance and extending its lifespan. By understanding the oxidation process, assessing the degree of oxidation, and employing appropriate cleaning methods, the shine and beauty of aluminum surfaces can be effectively restored. Additionally, implementing preventive measures and establishing maintenance procedures will help prevent future oxidation and ensure long-term preservation. With proper care, your aluminum products will remain vibrant and durable, adding beauty and functionality to your surroundings.