1. Steps of 12 foot aluminum boat building

Making a 12 foot aluminum boat requires specialized skills, tools, and materials. Here is a general overview of the process you may find it useful.

1. Design and Plans: Obtain or create detailed plans for the 12 foot aluminum boat. These plans will provide measurements, specifications, and instructions for each component.

2. Materials and Tools: Gather all the necessary materials and tools for the construction. This typically includes marine grade aluminum sheets, rivets, epoxy adhesive, fiberglass cloth, marine-grade plywood for transoms and seats, and specialized boat-building tools such as rivet guns, saws, drills, and clamps.

3. Hull Construction: Start by building the hull. Cut the aluminum sheets according to the plans and join them together using rivets or welding techniques. Ensure proper alignment and reinforcement for strength and stability. Use epoxy adhesive to seal any gaps or joints.

4. Transom and Seats: Construct the transom at the back of the boat using marine-grade plywood. Attach it securely to the hull. Build seats using the same plywood or other suitable materials, ensuring they are properly positioned and secured.

5. Deck and Flooring: If desired, add a deck and flooring to the boat using marine-grade plywood or other suitable materials. This will provide a stable and comfortable surface for occupants.

6. Finishing and Detailing: Sand down any rough edges or surfaces and apply a protective coating to the aluminum hull. Consider adding fiberglass cloth and epoxy resin for added durability and water resistance. Paint or apply a marine-grade finish to the exterior of the boat.

7. Installations and Features: Install any additional features or accessories, such as oarlocks, cleats, navigation lights, and seating cushions, as per your design and needs.

8. Testing and Safety: Before launching the boat, ensure it meets safety standards and regulations. Conduct a thorough inspection, including checking for any leaks, ensuring proper flotation, and verifying that all components are securely fastened.

Bear in mind that making a 12 foot aluminum boat necessitates knowledge of metalworking, carpentry, and boatbuilding procedures.

2. Gather Required Materials

If we want to construct a 12 foot aluminum boat, the following materials are needed:

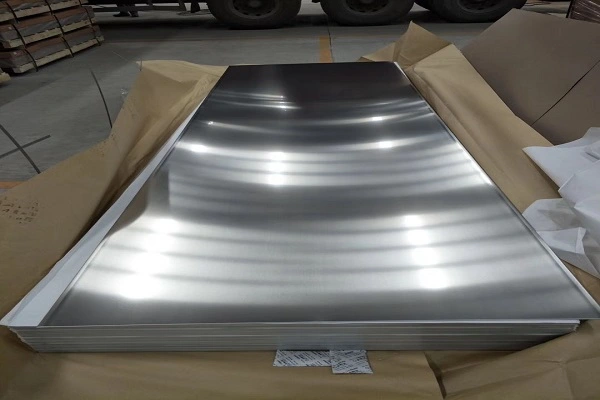

1. Marine-Grade Aluminum Sheets: Select marine-grade aluminum sheets for the boat’s hull construction. The thickness of the aluminum sheets will depend on the design and intended use of the boat. Commonly used alloys include 5052 and 5083 aluminum.

2. Rivets: Aluminum boat construction often involves the use of rivets to join the aluminum sheets together. Choose appropriate aluminum rivets based on the thickness of the sheets and the specific requirements of your boat design.

3. Epoxy Adhesive: Epoxy adhesive is used for sealing joints, gaps, and seams in the aluminum boat construction. Select a marine-grade epoxy adhesive suitable for bonding aluminum surfaces.

4. Fiberglass Cloth and Resin: Fiberglass cloth and epoxy resin can be used to reinforce certain areas of the boat, such as the transom or areas prone to stress. The fiberglass cloth provides added strength and stability to the aluminum structure.

5. Marine-Grade Plywood: Marine-grade plywood is commonly used for constructing transoms, seats, decks, and other wooden components of the boat. Ensure that the plywood is specifically designed for marine applications and resistant to water and rot.

6. Transom Material: The transom is an important structural element at the back of the boat. It can be made from marine-grade plywood or other suitable materials like aluminum or composite panels.

7. Framing and Reinforcement: Depending on your boat design, you may need additional framing materials, to provide structural support and reinforcement for the hull and other components.

8. Hardware and Fittings: Various hardware and fittings are required for assembling the boat, including stainless steel or aluminum screws, bolts, nuts, hinges, cleats, oarlocks, and other fasteners.

9. Paint and Coatings: Use marine grade paint or color coated aluminum to protect the aluminum surface from corrosion and the harsh marine environment. Choose paints that are specifically formulated for aluminum and provide good adhesion and durability.

10. Safety Equipment and Accessories: Consider including safety equipment and accessories, such as flotation devices, navigation lights, cleats, and other components required by local regulations or for your specific boating needs.

Finding proper and high-quality materials and equipment can be difficult, but this is the first stage in boat construction. Finding vendors, comparing costs, and assuring the availability of required components can all take time and effort.

Aluminum boats are constructed with صفائح الألمنيوم as the framework, which is the most significant aspect in keeping the boat stable, and we must be caution when selecting aluminum sheets.

3. Choose the best aluminum sheets for your boat.

Knowing how to choose the best aluminum sheets:

1.How to Evaluate Aluminum Sheets Quality

2. A Series of Physical Property Examinations

3.How to Select the Best Supplier

When selecting aluminum sheets for the hull, choose 5xxx series aluminum, such as 5052 or 5083 alloy. These alloys are suitable for boat construction due to their superior corrosion resistance and strength.

The following methods can be used to evaluate the quality of aluminum sheet:

Examine the appearance of the aluminum sheet to ensure that the surface is smooth and free of visible dents, defects, or cracks.

Dimensional measurement: To guarantee that the aluminum sheets fits your specifications, use appropriate tools to measure its size and thickness.

Chemical Composition Analysis: Conduct a chemical composition analysis to discover if the aluminum sheet’s composition satisfies your specifications.

Physical property testing methods can also be used to evaluate the quality of aluminum sheets, but they necessitate specific equipment and laboratory support

For example: Tensile Strength Test: Tensile testing determines an aluminum plate’s tensile strength, which is the greatest force the material can withstand before breaking under tensile loading.

Yield strength testing: Tensile or compression testing is used to determine the maximum stress at which a sustainable plastic deformation of the material begins to occur.

Elongation test: Tensile testing used to determine the elongation of an aluminum plate, i.e. the degree of plastic deformation that can occur in the material before fracture.

Hardness testing: The hardness of aluminum plates is tested using hardness testing devices (e.g., Brinell hardness tester, Rockwell hardness tester) to determine their resistance to compression or abrasion.

Impact Strength Test: An impact test is used to determine the impact strength of an aluminum plate, i.e. the material’s durability and toughness when subjected to an impact load.

Bending test: Bending tests are used to evaluate the bending properties of aluminum plates, including bending strength and bending deformation.

4. Do not forget to clean and take proper care of your boat

Cleaning your 12 foot aluminum boat is a vital aspect of keeping it looking good and extending its lifespan. Following is how to clean a 12 foot aluminum boat step by step:

1. Gather Supplies: Gather all of the cleaning supplies you’ll need, such as a soft-bristle brush or sponge, a bucket of warm water, mild detergent or boat soap, aluminum cleaner, a hose or pressure washer, and a soft microfiber or chamois towel for drying.

2. Rinse the Boat: Begin by rinsing the boat thoroughly with clean water to remove any loose debris, filth, or salt residue. Rinse the exterior thoroughly with a hose or pressure washer, including the hull, deck, and other surfaces.

3. Create Cleaning Solution: Put some mild dish soap or detergent into a pail of warm water. Avoid using harsh chemicals or abrasive cleansers on the metal surface.

4. Clean the Boat: Using a soft-bristle brush or sponge, carefully scrub the metal surfaces, paying special attention to areas with tenacious dirt or stains. To properly remove dirt, use back-and-forth or circular motions.

5. Aluminum Cleaner: If you have a lot of oxidation or stains on your 12 foot aluminum boat, you should use a professional aluminum cleaner. Follow the directions on the cleaner’s label, apply it to the problematic areas, then scrub gently with a brush or sponge. Once the stains have been cleared, carefully rinse.

6. Rinse Again: After cleaning, carefully rinse the boat with fresh water to remove any remaining soap or cleaning solution. Ensure that all areas, including those that are difficult to access, are completely cleaned.

7. Dry the Boat: To dry the boat thoroughly, use a soft microfiber or chamois cloth. Wipe down all surfaces, including the hull, deck, and any aluminum fittings or accessories, to avoid water marks or mineral deposits.

8. Waxing and Protection: Apply a marine grade wax or aluminum protectant to the boat’s surface if required. This will provide an additional layer of protection from UV rays, saltwater, and other environmental factors.

Cleaning the aluminum boat on a regular basis is recommended to avoid the collection of dirt, grime, and salt deposits.

It is also vital to inspect the boat during the cleaning process for any signs of damage, such as rust or loose fittings. To ensure the boat’s integrity and longevity, address any defects as soon as possible.

5.Other difficulties you might encounter when constructing a 12 foot aluminum boat

Building a 12 foot aluminum boat can be a gratifying experience, but it is not without its problems. The following are some frequent obstacles that people may experience when designing a 12 foot aluminum boat:

1. Expertise and skill requirements: Boatbuilding necessitates a specific level of ability and expertise in a variety of disciplines such as woodworking, fiberglassing, electrical systems, and marine engineering. During the construction process, a lack of knowledge or familiarity with these skills might cause problems.

2. Time and commitment: Building a 12 foot aluminum boat is a time-consuming endeavor that necessitates a large time and effort investment. Depending on the size and intricacy of the boat, completion could take months or even years. During the construction process, balancing other personal and professional commitments might be difficult.

3. Cost management: While building a 12 foot aluminum boat can save money over buying a ready-made boat, it is critical to control costs efficiently. Unexpected charges, design or material modifications, and the necessity for specialist tools or equipment can all have an impact on the overall budget. To stay inside the specified financial restrictions, meticulous planning and monitoring are required.

4. Technical difficulties: Boatbuilding entails a number of technical concerns, such as structural integrity, stability, propulsion systems, and electrical wiring. It might be difficult to ensure that the boat follows safety requirements and regulations, especially for first-time builders who lack prior expertise or experience in marine engineering.

5. Problem-solving and troubleshooting: Boatbuilding frequently entails unforeseen challenges and problems that necessitate innovative problem-solving abilities. During construction, issues such as fitting components, aligning structures, or overcoming technological challenges may develop. It is critical to be able to diagnose and find realistic solutions.

6. Patience and perseverance: Building a 12 foot aluminum boat is a lengthy endeavor that demands patience, persistence, and a positive attitude. It is critical to remain motivated and devoted throughout the process, even when faced with setbacks or hurdles.

This 12 foot aluminum boat can provide you with a private leisure space where you can relax, enjoy tranquility, and spend quality time with your family or friends. It also brings you closer to nature, allowing you to observe marine life, birds, and other aquatic creatures, experiencing the wonders of the natural world. You can explore the nearby coastlines, islands, rivers, or lakes, discovering more natural scenery and landmarks.