Aluminum Coil For Automobile

Aluminum coil for automobile, becoming a crucial component in vehicle manufacturing. An integral part of this transformation is the widespread use of aluminum coils in automotive production. These coils, which are flat-rolled aluminum sheets, play a vital role in modern car manufacturing by offering versatility and advantages that extend beyond body panels to include structural elements. Henan Yongsheng Aluminum is a trusted industry leader in producing top-quality aluminum coil for automobile. We prioritize meticulous attention to detail to ensure that every batch of aluminum we manufacture meets the highest standards of purity, strength, and consistency. Whether you operate in aerospace, automotive, construction, or any other industry, our aluminum is engineered to deliver outstanding performance, durability, and versatility.

Product Introduction

Utilizing aluminum coil for automobile manufacturing provides several significant advantages. One key benefit is its lightweight nature, as aluminum weighs significantly less than steel. This lightweight characteristic contributes to improved fuel efficiency and reduced emissions, making it an optimal choice for automakers striving to enhance environmental performance. By incorporating aluminum coils into the manufacturing process, weight reduction can be achieved without compromising the structural integrity of the vehicle, ultimately enhancing overall performance.

Moreover, aluminum coil shows fantastic anti-rust characteristics, unlike traditional steel components that are susceptible to rust and deterioration over time. This inherent corrosion resistance makes sure greater longevity and durability, making it particularly advantageous in regions with harsh climates or areas exposed to salted roads during winter.

Another notable advantage of aluminum coil is its impressive formability. Aluminum is highly malleable, allowing for intricate shaping and forming of many kinds of automotive parts. This flexibility empowers designers and engineers to create intricate and aerodynamic body panels that not only enhance aesthetics but also improve aerodynamic efficiency. What’s more, aluminum coil easily lends itself to various welding techniques, simplifying the assembly process for automotive manufacturers.

Specifications

| Alloy | 3003/3004/5052 |

| Temper | O, H24, H32 |

| Thickness(mm) | 0.21-3.0mm |

| Width(mm) | 16-2200mm |

| MOQ | 1 Tons |

| Delivery | Ready stock: 7-10 days, future goods: 15-30 days |

| Price term | EXW,FOB,CIF,CFR,CNF,etc. |

| Payment | L/C,T/T,Western Union,etc. |

| الشهادات | ISO9001&GS&ROHS&FDA&TUV&ISO&GL&BV,etc. |

Product Application

Aluminum coil plays a vital role in various automotive components, making significant contributions to the overall performance, safety, and efficiency of vehicles. Its applications in automotive manufacturing include:

- Body Panels: Aluminum coil is extensively used in fabricating lightweight body panels such as hoods, doors, fenders, and trunk lids. Leveraging the lightweight nature of aluminum, these panels reduce the overall weight of the vehicle, leading to improved fuel economy and enhanced performance.

- Chassis and Structural Components: Aluminum coil is employed in constructing chassis components like subframes, suspension parts, and cross members. These components offer strength and rigidity while simultaneously reducing weight, resulting in enhanced handling, maneuverability, and overall vehicle dynamics.

- Heat Exchangers: Aluminum coil finds application in manufacturing heat exchangers like radiators and condensers. These essential components play a critical role in engine cooling and maintaining optimal operating temperatures. The high thermal conductivity of aluminum enables efficient heat transfer, ensuring effective engine cooling performance.

- Wheels: Aluminum coil is utilized in producing lightweight aluminum wheels, which not only enhance the aesthetic appeal of a vehicle but also contribute to improved handling, reduced unsprung weight, and enhanced fuel efficiency. Aluminum-based wheel rims provide strength and durability while keeping weight to a minimum.

- Closures and Trim: Aluminum coil is employed in the production of closures such as doors, hatches, and tailgates. Additionally, it is used for decorative trim elements, enhancing the visual appeal of the vehicle while providing protection against wear and tear.

Product Advantages

The market of aluminum coil for automobile has witnessed significant growth in recent times, primarily due to the numerous benefits offered by aluminum coil. The lightweight nature of aluminum has emerged as a crucial factor in assisting automakers in meeting stringent fuel efficiency and emission regulations. Consequently, there is a rising demand for vehicles that extensively incorporate aluminum. Moreover, aluminum’s exceptional recyclability aligns with the increasing importance placed on sustainability and environmental consciousness within the automotive industry.

The versatility of aluminum coil alloys allows manufacturers to tailor the material’s properties to meet specific application requirements. By carefully selecting the alloy composition and applying appropriate heat treatments, they can achieve a balance between strength, formability, and corrosion resistance, thereby optimizing the performance of various automotive components. Furthermore, advancements in aluminum coil manufacturing technologies have resulted in improved surface finishes and coatings. These enhancements not only enhance the aesthetic appeal of vehicles but also provide additional protection against corrosion and wear.

The growth of the automotive aluminum market is further fueled by the growing focus on electric vehicles (EVs). Aluminum’s lightweight properties are particularly advantageous in EVs, as reduced weight contributes to extended driving range and improved vehicle efficiency. As the demand for EVs continues to surge, the utilization of aluminum coil in their production is expected to correspondingly increase.

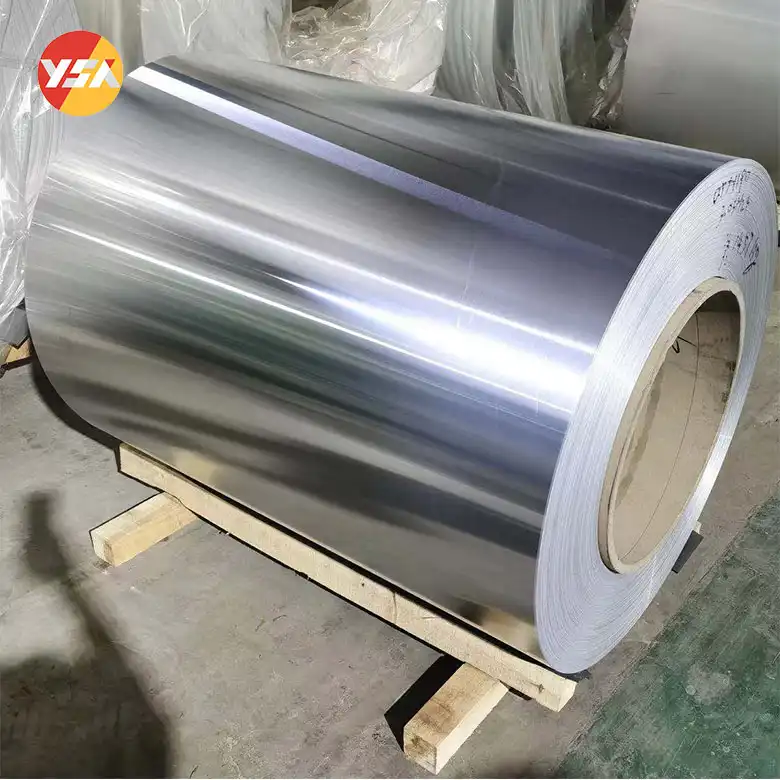

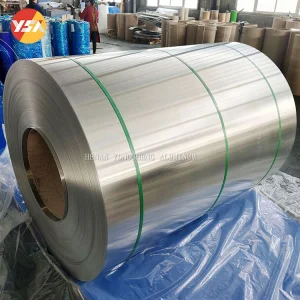

Product & Packaging Photos

Why Choose Us

Yongsheng Aluminum is a leading aluminum products manufacturer&supplier in China with 25 years of export experience. Our outstanding product quality, price, and always on-time delivery has won us many long term partners and gained a great reputation worldwide. We provide one-stop product solution for both CC&DC aluminum products.

Business Handling Processes