1 4 Aluminum Plate

Alloy: 1050 1060 1100 3003 3105 5052 6061 6063, etc

Temper: O, H16, H18, H22, H28, H36, H112, T3, T6, etc

Thickness: 6.35 mm

Size: 4×8, 4×10, 5×8, 5×10, cuastomized

MOQ: 1 Ton

Price Term: FOB, CIF, CFR, CNF, etc.

What is the Thickness of 1 4 Aluminum Plate ?

1 4 aluminum plate is 1/4 inch in inches (0.25 inches).

1 4 aluminum plate is an aluminum plate with a thickness of 6.35mm in millimeters.

YSA has 25 years of experience in aluminum plate production and is a manufacturer located in Gongyi City, Henan Province. We can also supply 2mm aluminum sheet, 3mm aluminum sheet, 125 aluminum plate, 4×10 aluminum sheet, 4×8 aluminum sheet, etc. If you have any questions feel free to ask.

Product Specifications

| Name | 1 4 inch aluminum sheet |

| Temper | O,H12,H22,H24,H26,H28,H32, H111, etc |

| Thickness | 0.25 inch/ 6.35mm |

| Width | 100-2600mm |

| Length | Customized |

| MOQ | 1 Ton |

| Sample | Free |

| Surface treatment | Mill Finish, Coated, Powder Coated, Anodized, Mirror, Embossed, checkered, etc. |

| Delivery Time | 7-25 days after order confirmation |

| Standards | GB/T 33227-2016、JIS H4000、ASTM B209、EN 485 |

| Price Terms | FOB, CIF, CFR, CNF, etc. |

Aluminum 1 4 Sheet Weight Calculation

The weight of a 1 4 aluminum plate with a specified thickness is strongly linked to its size.

As a result, before calculating the weight of a 1/4 aluminum plate, the size must be determined. For calculating the weight of a 4×8 1/4 aluminum sheet, let’s use the following example:

|

1 4 aluminum sheet 4×8

|

|

| Density | Approximately 0.0975 lbs/cubic inch |

| Width | 4 foot/1220 mm/48 inches |

| Length | 10 foot/3048 mm/120 inches |

| Thickness | 0.25 inch |

| 6.35 mm | |

| Volume | 1152 cubic in |

| Wight | 112.32 lbs |

Therefore, the weight of 4×8 1 4 aluminum plate is approximately 112.32 lbs or 50.947 kg.

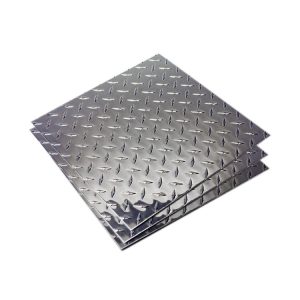

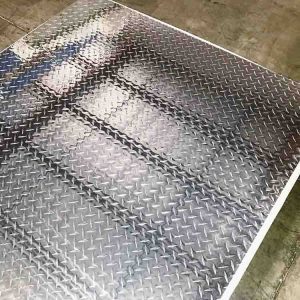

1 4 Inch Thick Aluminum Sheet: Surface Treatment

|

1 4 anodized aluminum sheet

|

1 4 brushed aluminum sheets | 1 4 diamond plate aluminum sheet |

| 1 4 expanded aluminum sheet | 1 4 inch gold colored aluminum sheets

|

1 4 perforated aluminum sheet |

Common Alloy:

1/4 5052 Aluminum Sheet:

6061 1 4 Aluminum Sheet:

- Aircraft structural parts: fuselage panels, wing panels, tail fins, etc.

- Spacecraft components: satellite casings, brackets and connectors, etc.

- Body panels and chassis components: doors, hoods, roofs, chassis supports, etc.

- Suspension system and chassis components: suspension arms, shock absorber mounts, steering components, etc.

How to Bend 1 4 Aluminum Sheet ?

- Prepare the following equipment: 1/4″ aluminum plate, table, clamps, ruler, mallet or hammer, and bending brake or similar instrument.

- Mark the bending lines: Use a tape measure and a pencil to trace the desired bend lines on the metal sheet. Make sure your lines are straight and exact.

- Fix the plate: Place the 1 4 aluminum plate on the table and fasten it with clamps. Make sure the panels are securely fastened to prevent movement.

- Create the curved edge: If you have a curved brake, align the marked curve line with its curved edge. If you don’t have a bend stop, use a ruler as a guide to make the curved edge. Place a ruler along the designated curve line and apply hard pressure to make a crease or score line.

- Begin bending: Using the bend brake, gently apply pressure to bend the 1 4 aluminum plate along the specified line. If you’re using a straight edge, position it below the score line and tap the board gently with a mallet or hammer to bend it over the edge. Don’t pound too hard or you’ll ruin the board.

- Continue bending: To make greater bends, move the ruler or bend stop along the highlighted line and bend until you reach the required angle. Take your time and make minor tweaks as necessary.

How to Cut 1 4 Aluminum Sheet ?

For aluminum plates with a thickness of 6.35mm, you can use a shearing machine or a high-speed circular saw to cut them. Specific steps are as follows:

Shearing machine operating steps:

Correctly configure the shearing machine’s cutting thickness and blade. Place the 1/4 aluminum plate on the shearing machine at the position of the cutting line, then use the clamping device to secure it to the workbench and align the shearing blade with the starting point of the cutting line. Starting position and cutting step by step. Keep the cutting speed steady and don’t push the shear too hard. Once the cut is finished, inspect the quality and precision of the cut line. If required, polish the edges using a file or sandpaper.

High-speed circular saw operation steps:

Use a ruler and pencil to outline the cutting lines on the metal plate. Choose a high-speed circular saw blade designed for aluminum. Place the aluminum plate on a firm work surface and secure it using clamps. Place the high-speed circular saw on one side of the cutting line and begin the cutter. Adjust the cutting speed based on experience and current conditions. Push the circular saw forward along the cutting line while keeping a consistent cutting speed and pressure.

How Much Does a 4×8 Sheet of 1/4 Aluminum Cost ?

The price of a 4×8 1/4 aluminum sheet is highly tied to the current price of aluminum ingots, processing costs, surface treatment methods, logistics and transportation expenses, labor costs, and so on. Please contact us directly for exact pricing, and we will promptly supply you with the most recent quote.

YSA is a leading Chinese aluminum company. We insist on being customer-centric and strictly control product quality to ensure that aluminum products pass quality inspections, are complete and clean during transportation, and do a good job in waterproof and moisture-proof packaging to prevent collisions, providing OEM services and free samples.

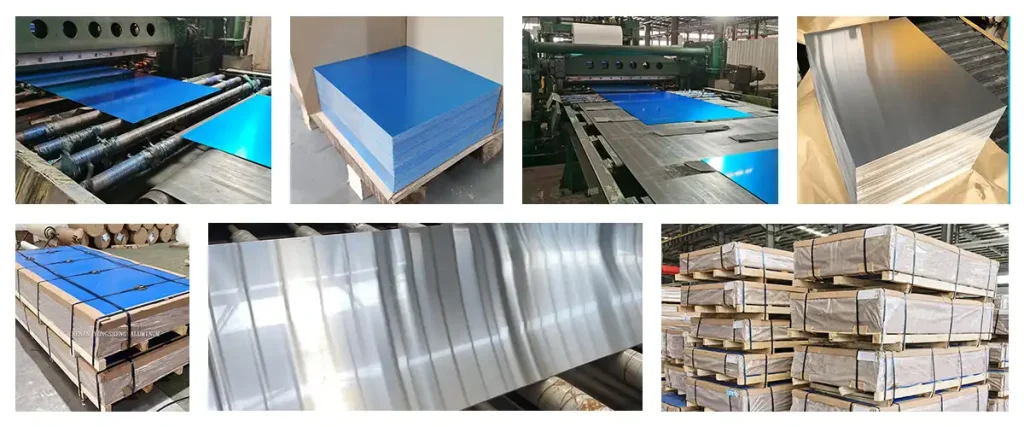

Product & Packaging Photos

Why Choose Us

Yongsheng Aluminum is a leading aluminum products manufacturer&supplier in China with 25 years of export experience. Our outstanding product quality, price, and always on-time delivery has won us many long term partners and gained a great reputation worldwide. We provide one-stop product solution for both CC&DC aluminum products.

Business Handling Processes