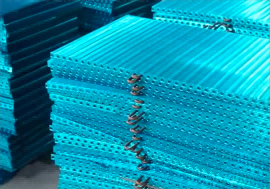

Fin heat exchangers play a crucial role in various industrial and household equipment such as air conditioners, refrigeration systems, and heat pumps. Aluminum strips have become the preferred material for fin heat exchangers due to their excellent properties. Here are the key benefits of using aluminum strips in fin heat exchangers:

Excellent Thermal Conductivity

Aluminum strips possess high thermal conductivity, allowing them to transfer heat quickly and efficiently, thereby enhancing the heat exchanger’s performance. With a thermal conductivity of approximately 237 W/m·K, aluminum excels in heat transfer, facilitating rapid dissipation and cooling.

Lightweight

The density of aluminum is only 2.7 g/cm³, roughly one-third that of copper. This results in lighter fin heat exchangers, which reduce the overall weight of the equipment. This weight reduction lowers transportation and installation costs, making aluminum particularly advantageous in applications that require lightweight designs, such as automotive and aerospace industries.

Good Corrosion Resistance

Aluminum forms a dense oxide film on its surface when exposed to air, protecting the underlying material from further corrosion. This natural resistance to oxidation ensures that aluminum strip fin heat exchangers maintain stable performance over long-term use, reducing the frequency of maintenance and replacements, and extending the lifespan of the equipment.

Excellent Workability

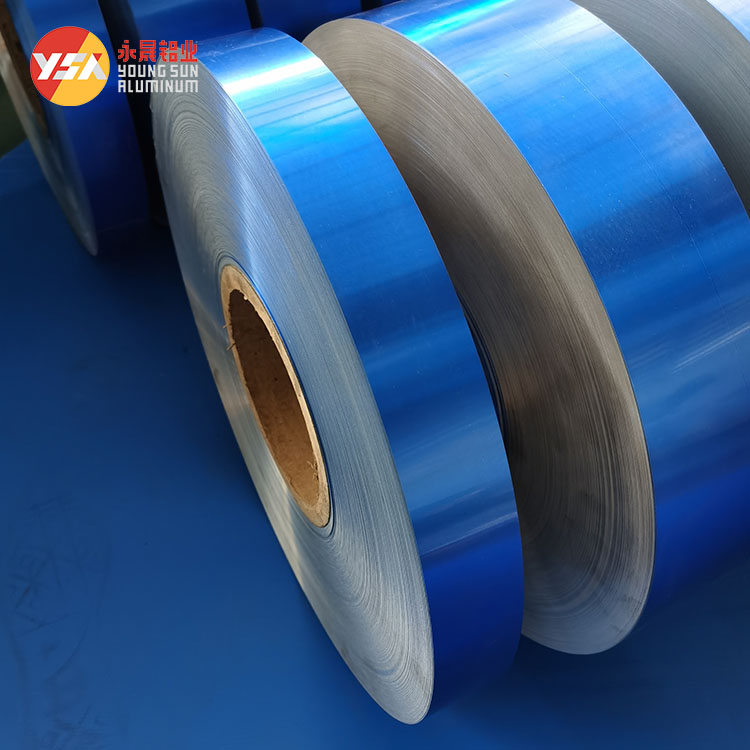

Aluminum’s workability allows it to be processed through rolling, extrusion, drawing, and various other methods to create complex fin structures. This flexibility in manufacturing processes enables aluminum strips to meet diverse heat exchanger design requirements, offering greater design freedom.

Cost-Effectiveness

Compared to copper, aluminum is less expensive as a raw material. Additionally, aluminum production can further reduce costs through the recycling of aluminum scrap during manufacturing. By choosing aluminum strips for fin heat exchangers, manufacturers can achieve high performance while effectively controlling production costs, enhancing product competitiveness in the market.

Environmental Friendliness

Aluminum is a fully recyclable material with a relatively simple and energy-efficient recycling process. Fin heat exchangers made from aluminum strips can be recycled at the end of their lifecycle, minimizing environmental impact and aligning with modern environmental protection principles and requirements.

Conclusion

In summary, aluminum strips offer significant advantages in fin heat exchangers, including excellent thermal conductivity, lightweight, corrosion resistance, workability, cost-effectiveness, and environmental friendliness. These benefits make aluminum strips an ideal material for fin heat exchangers, providing reliable solutions for various heat exchange applications. With advancements in technology and expanding applications, the future prospects of aluminum strips in fin heat exchangers are promising.