1050 Aluminum Strip

Alloy: 1050

Temper: O, H12, H14, H16, H18, H22, H24, H32, etc

Width: 3mm-2600mm

Thickness: 0.1 mm-6.5mm

Surface Treatment: Mill finish, coated, powder coated, anodized, polished mirror, embossed, etc.

Delivery Time: 7-25 days after order confirmation.

YSA 1050 Aluminum Strip Introduction:

1050 aluminum strip is soft in texture, has high conductive aluminum and good thermal conductivity. It can be plastically processed and processed into plates, strips, foils and various extruded products. Heat treatment in the form of annealing is mainly used in electronic and electrical fields such as transformers, cables, optical cables, fin heat dissipation, etc. Our company specializes in stocking a large number of aluminum plates, aluminum coils, and aluminum strips of various series. We can provide aluminum strip slitting, aluminum strip slitting and other services according to customer requirements. We provide free samples. If you have any needs, please contact us immediately through this website!

1050 Aluminum Strip Technical Parameters:

| Alloy | 1050 Aluminum Strip |

| Temper | O~H112,etc |

| Processing Service | Bending, Decoiling, Welding, Punching, Cutting |

| Surface treatment | Mill Finish, Coated, Powder Coated, Anodized, Mirror, Embossed, checkered, etc. |

| Delivery time | 7-25 days after order confirmation |

| Loading Port | Qingdao Port,Tianjin Port,Shanghai port. |

| Price terms | FOB, CIF, CFR, CNF, Etc. |

| Certificate | ISO, RoHS |

| Standards | ASTM-B209,EN573-1,GB/T3880.1-2006 |

Chemical Composition:

| Element | Si | Fe | Cu | Mg | Mn | Ti | Zn | Al |

| Value | 0.25 | 0.35 | 0.05 | 0.03 | 0.05 | 0.03 | 0.05 | Min:99.5 |

1050 Aluminum Strip Advantages:

A: Smooth, no burrs.

B: High formability.

C: Corrosion resistance.

D: High purity.

E: Good reputation.

F: High quality.

G: Affordable.

H: Free samples.

YSA Aluminum Strip Packing:

FAQ:

What Is A 1050 Aluminium Grade?

1050 belongs to the 1xxx series aluminum alloys. In this series, the first number 1 indicates that the main alloy component is aluminum, and no other elements are added, so it is also called “industrial pure aluminum”. The purity of aluminum in 1050 alloy usually exceeds 99.5%. It is a soft aluminum alloy with strong electrical conductivity, so it is often used in electronic equipment and packaging fields.

What Is The Difference Between 1100 And 1050 Aluminium?

Both are 1000 series aluminum, with the main difference being that 1050 aluminum alloy contains more aluminum than 1100 aluminum. Due to the difference in purity, Aluminum 1100 is softer than 1050, has lower strength and hardness, and is easier to machine. On the contrary, the corrosion resistance of 1050 is stronger than aluminum 1100.

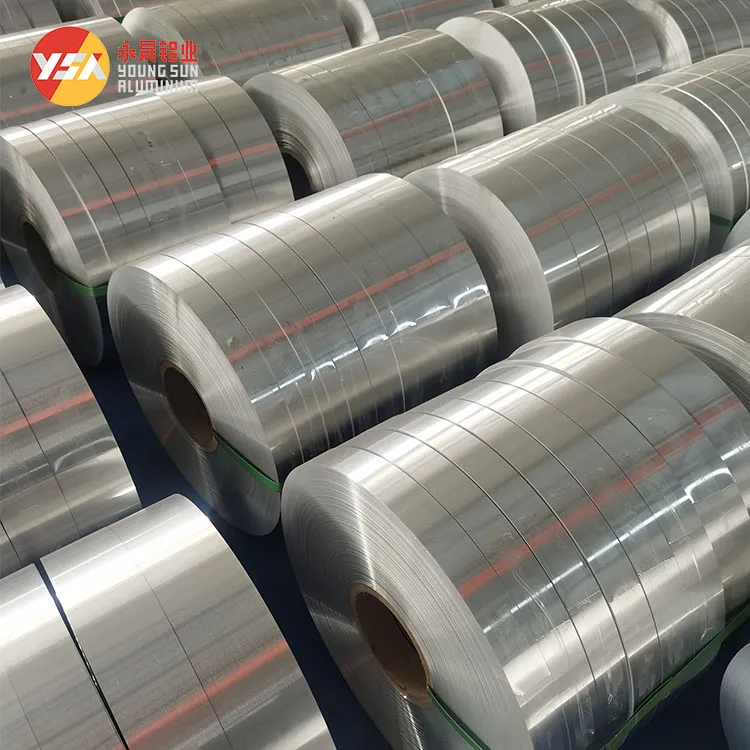

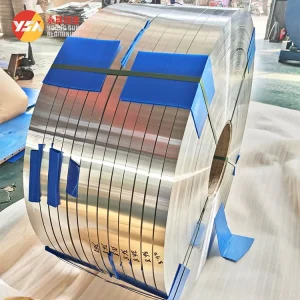

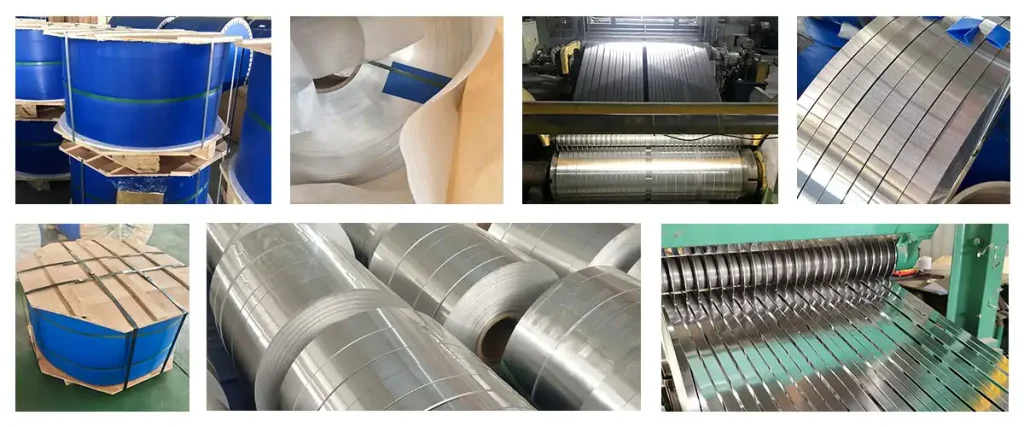

Product & Packaging Photos

Why Choose Us

Yongsheng Aluminum is a leading aluminum products manufacturer&supplier in China with 25 years of export experience. Our outstanding product quality, price, and always on-time delivery has won us many long term partners and gained a great reputation worldwide. We provide one-stop product solution for both CC&DC aluminum products.

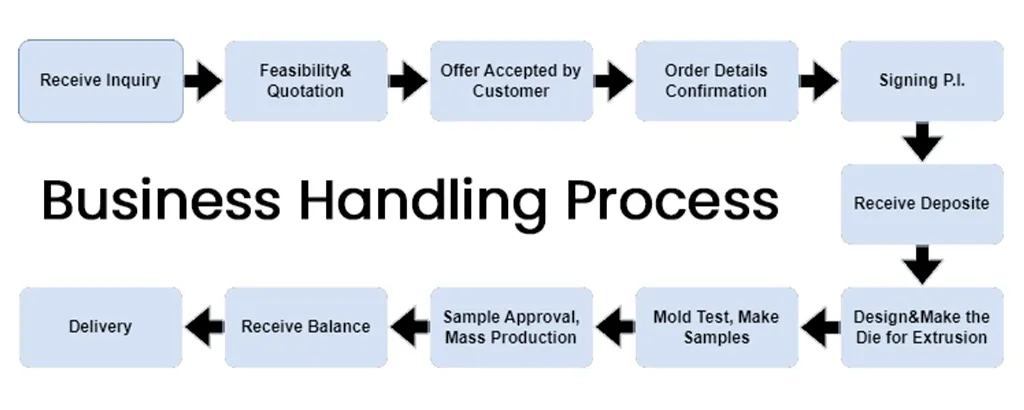

Business Handling Processes