6061 Aluminum Strip

Alloy model: 6061

Temper: T4, T6, T651, etc

Thickness: 0.1 mm-6.5 mm

Width: 3mm-2600mm

MOQ: 1 ton

Delivery: Ready stock: 7-10 days, future goods: 15-30 days

6061 Aluminum Strip Introduction:

6061 aluminum strip contains a lot of magnesium and silicon elements, has excellent processing performance, medium strength, is an alloy that can be strengthened by heat treatment, and can still maintain good operability after annealing. Widely used in industrial structural components, showing good corrosion resistance and weldability.

Parameters of 6061 Aluminum Strip:

| Processing And Forming | 6061 aluminum can be cut, machined, bent, welded, rolled, deep drawn and other processing processes. |

| Surface Treatment | Mill finish、coated、powder coated、anodized、polished mirror、embossed、etc. |

| Tolerances | As customer’s requirement |

| Loading Port | Qingdao Port,Tianjin Port,Shanghai port. |

| Price terms | FOB, CIF, CFR, CNF, etc. |

| Payment terms | L/C,D/A,D/P,T/T , West Union, Money Gram, Etc. |

| Standards | ASTM-B209,EN573-1,GB/T3880.1-2006 |

| Certificate | ISO, RoHS |

| Welding | Conventional argon arc welding, resistance spot welding, laser welding and other welding processes. |

| Heat Treatment | Solution treatment and aging treatment. |

| Forging | Hot forging, cold forging, etc. |

Heat Treatment Process:

1. Rapid annealing: heating temperature 350~410℃; depending on the effective thickness of the material, the holding time is between 30~120min; air or water cooling.

2. High temperature annealing: heating temperature 350~500℃; when the thickness of the finished product is ≥6mm, the holding time is 10~30min; when it is less than 6mm, the heat preservation time is until it is heated through; air cooling.

3. Low temperature annealing: heating temperature 150~250℃; holding time 2~3h; air or water cooling.

4. Homogenization: 570 degrees Celsius, heat preservation for 7 hours; air cooling.

6061 Aluminum Specification:

Chemical Composition:

|

Alloy |

Si | Fe | Cu | Mg | Mn | Cr | Zn | Ti | Ni | Zr |

Al |

| 6061 | 0.3-0.7 | 0.5 | 0.1 | 0.35-0.8 | 0.03 | 0.03 | 0.1 | – | – | – |

Remain |

Mechanical Properties:

- Tensile Strength: 310 MPa – 415 MPa

- Yield Strength: 276 MPa – 310 MPa

- Elongation: 12% – 16%

Physical Properties:

| Grade | 6061 |

| Density | 2.70 g/cm³ |

| Melting Point | 582 °C |

| Elastic Modulus | 69 GPa |

| Thermal Conductivity | 167 W/(m·K) |

| Electrical Conductivity | 43.9 MS/m |

| Specific Heat Capacity | 897 J/(kg·°C) |

Advantages of 6061 Aluminum Strip:

- High strength.

- Solderability.

- High corrosion resistance.

- Processable.

- Good thermal conductivity.

- Anti-fatigue.

- Easy to color.

- Formable.

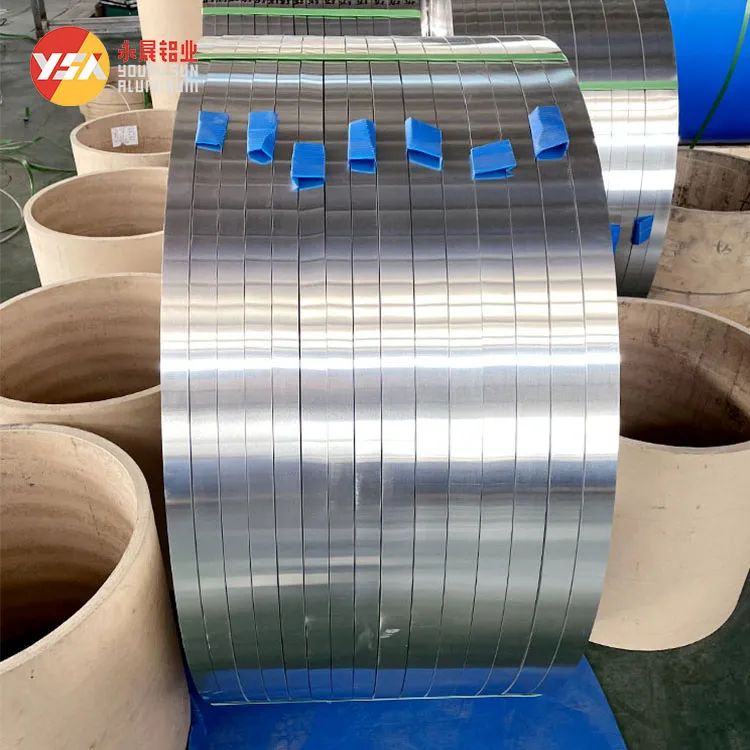

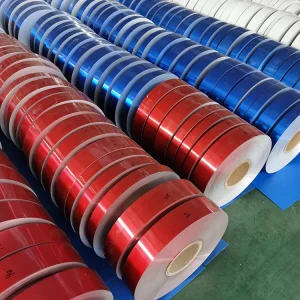

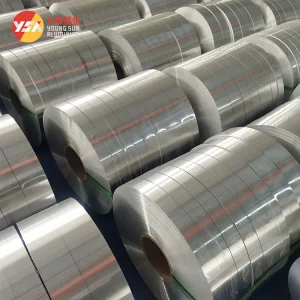

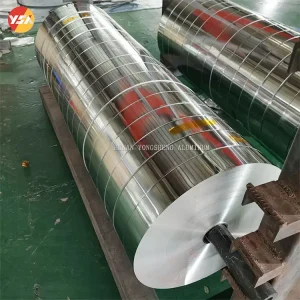

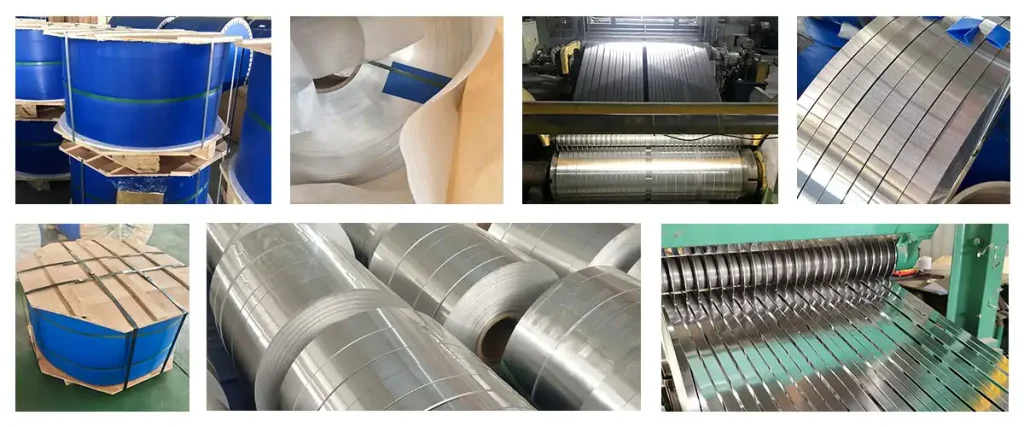

Product & Packaging Photos

Why Choose Us

Yongsheng Aluminum is a leading aluminum products manufacturer&supplier in China with 25 years of export experience. Our outstanding product quality, price, and always on-time delivery has won us many long term partners and gained a great reputation worldwide. We provide one-stop product solution for both CC&DC aluminum products.

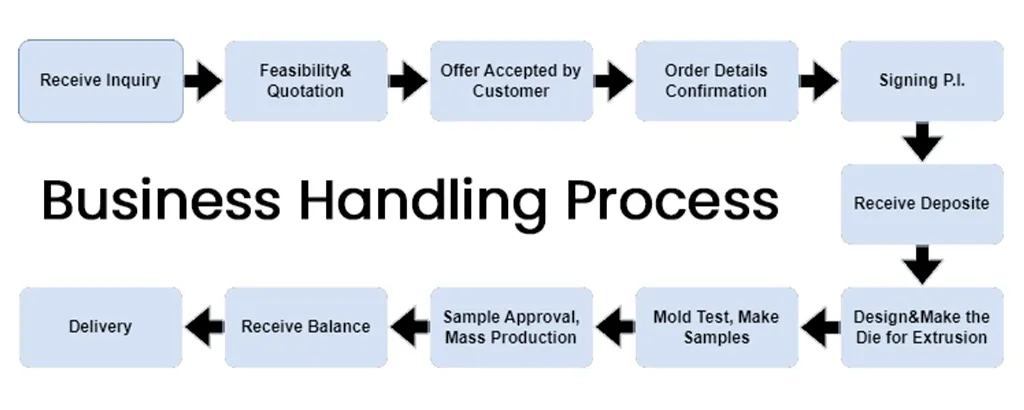

Business Handling Processes