Marine Grade Aluminum Plate

Alloy: 5083 Aluminum Plate

Temper: O, H32, H34, H36, H38, H111, H112

Width: 20mm-2600mm

Thickness: 0.2 mm- 12 mm, Customized

Delivery: Ready stock: 7-10 days, future goods: 15-30 days

Applications: Marine, automobile, grinding tools, etc.

Marine Aluminum Plate Introduction:

Marine grade aluminum plates are aluminum alloy plates specially designed for shipbuilding and marine engineering. They usually use high-strength, seawater-resistant aluminum alloys, such as 5xxx and 6xxx series aluminum alloys, such as 5083, 5086, 5454 and 6061, etc. It also has excellent mechanical properties, including high strength, tensile resistance and impact toughness to cope with the extreme conditions in the marine environment, such as large waves and impacts.

Due to the salt and humidity in seawater, marine aluminum plates need to have excellent corrosion resistance to prevent aluminum alloys from corroding and oxidizing in the marine environment. The manufacturing of marine aluminum plates usually needs to comply with international standards, such as ASTM (American Society for Testing and Materials) or EN (European Standard), etc., to ensure that the quality and performance of the product meet the requirements of international ship engineering.

Shipbuilding Aluminum Plate Details:

When it comes to marine grade aluminum plates, the most common one is 5083 aluminum plates. It is an aluminum-magnesium alloy with low density, high toughness, high corrosion resistance and weldability. It is mainly used on ship hulls and is characterized by high strength, good corrosion resistance, It has excellent weldability and ductility, and can adapt well to harsh marine environments.

| 5083 | Tensile Strength(MPa) | Yield Strength(MPa) |

Elongation(%) |

|

H22 |

290 | 145 | 16 |

|

H32 |

305 | 215 | 10 |

| H112 | 270 | 125 |

12 |

| H116 | 340 | 240 |

10 |

5083 Aluminum Plate Characteristics and Advantages:

In the shipbuilding industry, 5083 aluminum plates are mostly used in ship main decks, diesel engine pedestals, ship sides, and lower outer sides of ships. Has many advantages:

1. Higher specific strength and specific strain rate. The structural strength and size of a ship are closely related to the tensile strength and elasticity of the material, and the elasticity and density of aluminum alloy are roughly the same, making it the best choice for marine materials.

2. Electric welding has excellent weldability. 5083 aluminum plate has excellent welding cohesion and is not prone to cracks during electric welding.

3. Excellent corrosion resistance. Corrosion resistance is one of the key indicators of ship aluminum alloys. 5083 aluminum plate is a typical anti-rust treated aluminum plate with good corrosion resistance.

4. The relative density is small. The small specific gravity of aluminum alloy can reduce the weight of ship plates, save energy consumption and increase load capacity.

5. Environmentally friendly and pollution-free. Aluminum alloys have a high recycling rate, can be recycled and reused, and have good environmental protection.

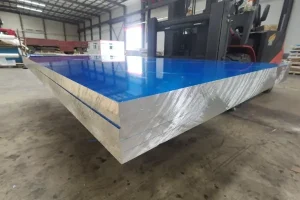

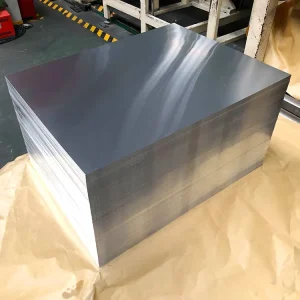

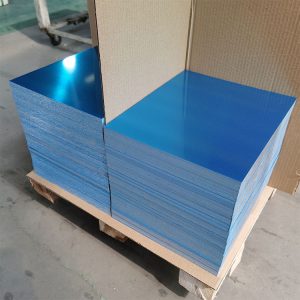

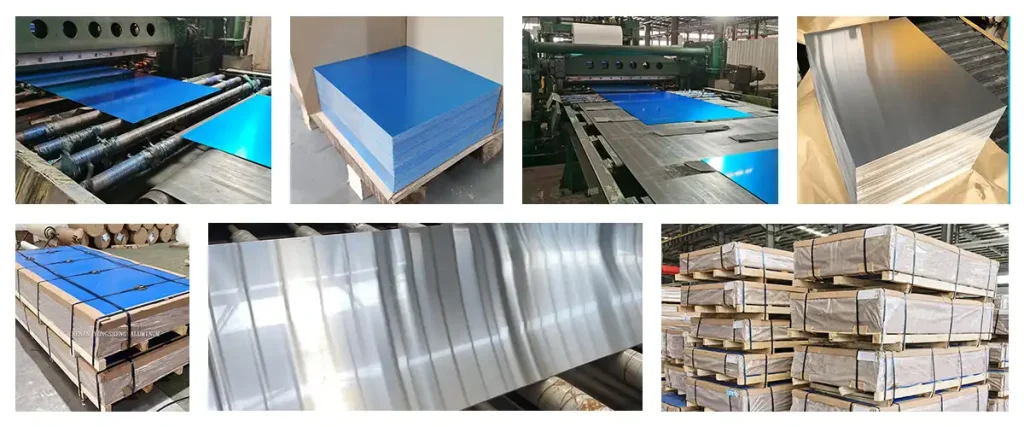

Product & Packaging Photos

Why Choose Us

Yongsheng Aluminum is a leading aluminum products manufacturer&supplier in China with 25 years of export experience. Our outstanding product quality, price, and always on-time delivery has won us many long term partners and gained a great reputation worldwide. We provide one-stop product solution for both CC&DC aluminum products.

Business Handling Processes