Marine Grade Aluminum Sheet for Boat

Alloy: 3000 5000 6000 series

Temper: O-H112, T3, T4, T351, etc

Thickness: 0.2-170mm

Width: 800-2600mm

MOQ: 1 Ton

Delivery Time: 7-25 days after order confirmation

What is Marine Grade Aluminum Sheet ?

Marine grade aluminum sheet for boats mostly use alloys: 5053, 5086, 5754, 6061 and other products. It has good corrosion resistance and is very suitable for applications in seawater and other environments. Marine grade aluminum sheets must meet requirements such as high strength and specific modulus, excellent welding performance, corrosion resistance and good hot and cold formability. Yongsheng Aluminum’s 5083 aluminum plates, 5754 aluminum plates, 6061 aluminum plates and other products have entered the shipbuilding market and are mainly used for ship decks, engine seats, ship sides, bottom outer plates and other components.

Product Specifications

| Alloy Series | 3003 5083 5754 6061, etc |

| Temper | O, H16, H32, H111, H116, H321, T6, T321, etc |

| Thickness | 0.2-170mm |

| Width | 800-2600mm |

| Surface Treatment | Mill Finish, Coated, Powder Coated, Anodized, Mirror, Embossed, checkered, etc. |

| MOQ | 1 Ton |

| Sample | Free |

| Delivery Time | 7-25 days after order confirmation |

| Standards | GB/T 33227-2016、JIS H4000、ASTM B209、EN 485 |

| Price Terms | FOB, CIF, CFR, CNF, etc. |

Marine Grade Aluminum Sheet for Boat Properties

Marine grade aluminum sheet for boats has several advantages, including light weight, high strength, strong corrosion resistance, and ease of manufacturing. Aluminum plates can help to lower the ship’s weight, boost its speed, reduce fuel consumption, reduce corrosion and maintenance workload, and lengthen the ship’s service life.

Marine Aluminum Sheet vs Regular Aluminum Sheet

One of the primary distinctions between marine grade and normal aluminum is corrosion resistance.

Marine grade aluminum (such as the 5000 series aluminum alloy) is more corrosion resistant than conventional aluminum, making it ideal for situations exposed to salt water or other corrosive substances.

Furthermore, marine-grade aluminum panels are known for their exceptional strength and durability in hostile marine environments, making them ideal for shipbuilding. Regular aluminum sheets are less corrosion resistant than marine aluminum sheets and are widely utilized in industries such as building, automobiles, electronics, and packaging.

Applications

Marine aluminum sheet for boat is widely utilized in the production of numerous types of ships, including yachts, cargo ships, and oil tankers. In addition to being utilized for the outside shell and interior structure of ships, marine aluminum plates can be employed as brackets, insulating materials, and other components for electrical systems and devices on ships.

Where to Buy Marine Aluminum Sheet

Yongsheng Aluminum has worked with numerous shipbuilding businesses throughout the world for many years. If you want to buy high-quality marine aluminum plates at a low cost, YSA is your best option. Our facility, located in Gongyi City, Henan Province, can manufacture and process aluminum plates on a big scale. We can manufacture marine aluminum sheets in large quantities in a variety of alloys, conditions, thicknesses, and widths, and provide factory costs.

FAQ:

Is 6063 aluminum marine grade ?

No, 6063 aluminum is not generally considered marine grade aluminum. Marine-grade aluminum refers to alloys specifically designed to enhance corrosion resistance and durability in marine environments exposed to salt water and other harsh conditions. Common marine grade aluminum alloys include 5083, 5086, and 6061, which offer superior corrosion resistance and strength properties compared to 6063. These alloys are commonly used in the construction of ships, shipbuilding, and other marine applications.

What aluminum for marine fuel tanks ?

The two most commonly used aluminum alloys for marine fuel tanks are 5052 and 5083.

5052 aluminum alloy is known for its good corrosion resistance, high strength and excellent formability. It is commonly used in marine oil tanks. 5083 aluminum alloy has excellent corrosion resistance in harsh seawater environments. It has excellent weldability and high strength and is suitable for building marine fuel tanks.

Both 5052 and 5083 aluminum alloys are approved by the American Boat and Yacht Council (ABYC) for use in marine fuel tanks.

What is the best marine grade aluminum for welding ?

5083 and 5086 are considered the most suitable marine grade aluminum for welding. Because of its excellent seawater corrosion resistance, 5083 aluminum alloy has good weldability and can still maintain strength after welding. It is suitable for various marine structures such as hulls, decks, and superstructures; 5086 aluminum alloy has excellent corrosion resistance and Weldability, often used in ship hulls, pressure vessels and other marine structures that require high strength and resistance to salt water corrosion.

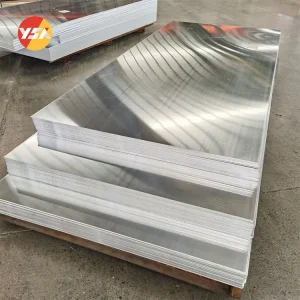

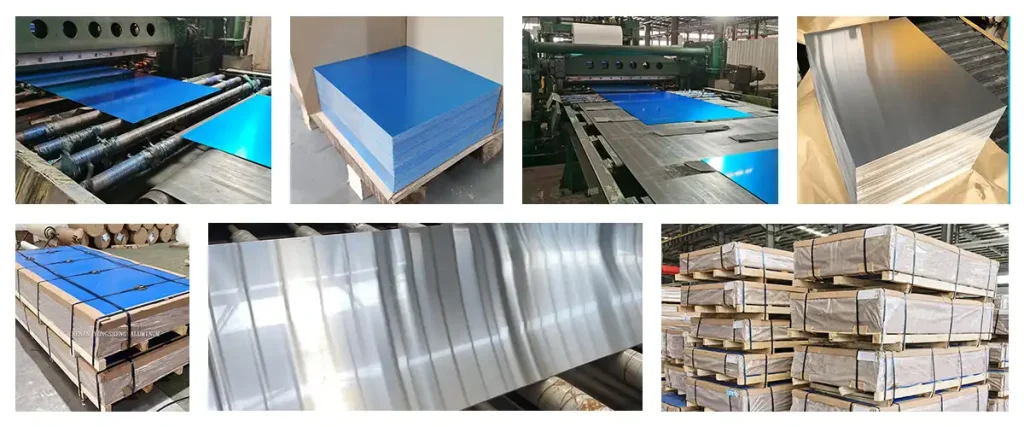

Product & Packaging Photos

Why Choose Us

Yongsheng Aluminum is a leading aluminum products manufacturer&supplier in China with 25 years of export experience. Our outstanding product quality, price, and always on-time delivery has won us many long term partners and gained a great reputation worldwide. We provide one-stop product solution for both CC&DC aluminum products.

Business Handling Processes