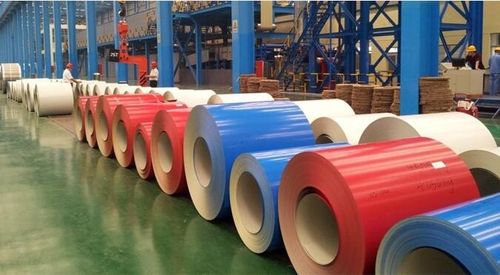

1、 After cleaning, chrome plating, roller coating, baking and other processing, the surface of the aluminum coil is coated with various colors of paint, which is also known as color coated aluminum coil.

2、Color aluminum is widely used in insulation boards, aluminum curtain walls, aluminum magnesium manganese roof systems, aluminum ceilings, and many other fields due to its advantages of light texture, bright colors, easy processing and shaping, and non rusting.

3、 Coated aluminum coils can be simply divided into: surface coated paint, divided into polyester (PE) coated aluminum coils and fluorocarbon (PVDF) coated aluminum coils due to different processing and usage purposes; Epoxy roller coated aluminum coil. Of course, there are also cases where one side is coated with fluorocarbon and the other side is coated with polyester; There are even cases where both sides are coated with fluorocarbon.

4、 The thickness of the coating can be divided into single coatings (4μm-20μm) ; Double coating (25μm-28μm) ; 3 coats (35μm-38μm) ; The surface patterns are diverse, also known as wood grain aluminum roll, stone grain aluminum roll, brick grain, camouflage aluminum roll, fabric aluminum roll, etc; Due to their different uses, they are often referred to as roofing materials (aluminum magnesium manganese roofing systems), ceiling materials (for aluminum alloy ceilings), and wire drawing boards (with wire drawing treatment on the surface).

The main characteristics of roller coated plates:

① Good temperature resistance, aluminum has a melting point of 660 degrees, which cannot be reached at normal temperatures.

② Highly environmentally friendly and resistant to discoloration, operated with a chromium free treatment solution; Roll coating paint contains active chemical molecules, which promote the formation of a protective layer on the surface of the material. Active chemical molecules are stable and easy to recycle, meeting environmental requirements.

③ Corrosion resistance is due to the tight oxide film on its surface, which has strong adhesion, oxidation resistance, strong acid and alkaline resistance, corrosion resistance, decay resistance, and resistance to ultraviolet radiation.

④ The color is uniform and long-lasting, with even and delicate colors. It is soft and bright, avoiding the individual color difference phenomenon of traditional spraying. No matter how large the ceiling area is, its color is consistent and long-lasting.

⑤ The combination of rigidity and toughness results in extremely high surface strength. The combination of rigidity and toughness allows for arbitrary cutting, slitting, bending, pressure balancing, drilling, connection fixation, and edge compression molding.