The transformation of aluminum discs into stretched can bodies is a sophisticated process vital in the manufacturing of cans used across various industries. This intricate process involves several meticulous steps aimed at achieving precision and quality. Let’s delve into the detailed process of machining aluminum discs into stretched can bodies.

Material Preparation

The process begins with the preparation of aluminum discs, ensuring they meet the required dimensions and specifications. These discs are typically cut or machined from aluminum sheets, providing the raw material for further processing.

Pre-Treatment

Before machining, the aluminum discs undergo pre-treatment to ensure surface cleanliness and readiness for processing. This may involve cleaning to remove oil and impurities and surface treatment to prevent oxidation or corrosion, safeguarding the material’s integrity.

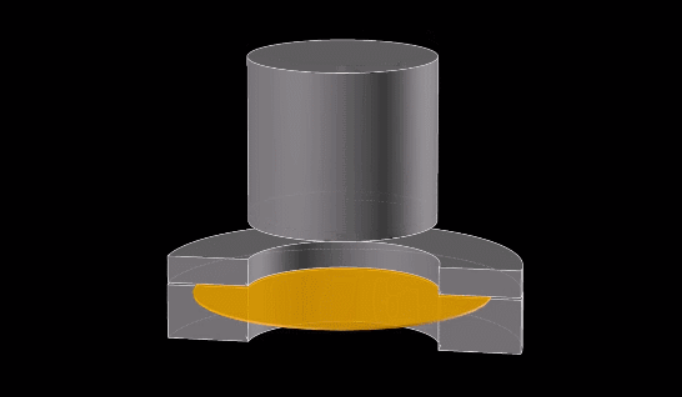

Disc Forming

Using specialized stretching equipment or molds, the aluminum discs are fed into forming machines for processing. Hydraulic presses or stretching machines apply controlled force and shape the discs progressively into the desired shape of can bodies. This stage demands precise control of temperature, pressure, and speed to ensure accurate forming and quality outcomes.

Forming Adjustments

Upon completion of stretching, adjustments may be necessary to fine-tune the dimensions and shape of the can bodies. This could involve trimming, cutting, or additional machining to meet specific design requirements and quality standards.

Welding (if required)

In certain cases, stretched can bodies may require welding to join seams or parts together. Welding processes involve cleaning, flux application, and using appropriate welding equipment to ensure seam integrity and structural strength.

Surface Treatment

Post-machining, the can bodies undergo surface treatment to enhance appearance and corrosion resistance. This may include painting, anodizing, or applying protective coatings to improve aesthetics and durability.

Quality Inspection

Throughout the production process, stringent quality inspections are conducted to ensure compliance with standards and specifications. Dimensional measurements, visual inspections, and seal integrity tests are among the checks performed to guarantee product quality.

Packaging and Transportation

Finally, the finished can bodies are packaged, labeled, and prepared for safe transportation and storage. Proper packaging ensures protection during transit and delivery to customers or designated locations.

Conclusion

The machining of aluminum discs into stretched can bodies involves a series of precise and controlled steps, each contributing to the production of high-quality cans. Through meticulous material preparation, forming processes, welding (if necessary), surface treatment, and rigorous quality checks, manufacturers ensure the delivery of cans that meet stringent standards and customer expectations. This comprehensive process underscores the importance of precision engineering and attention to detail in the production of stretched can bodies.