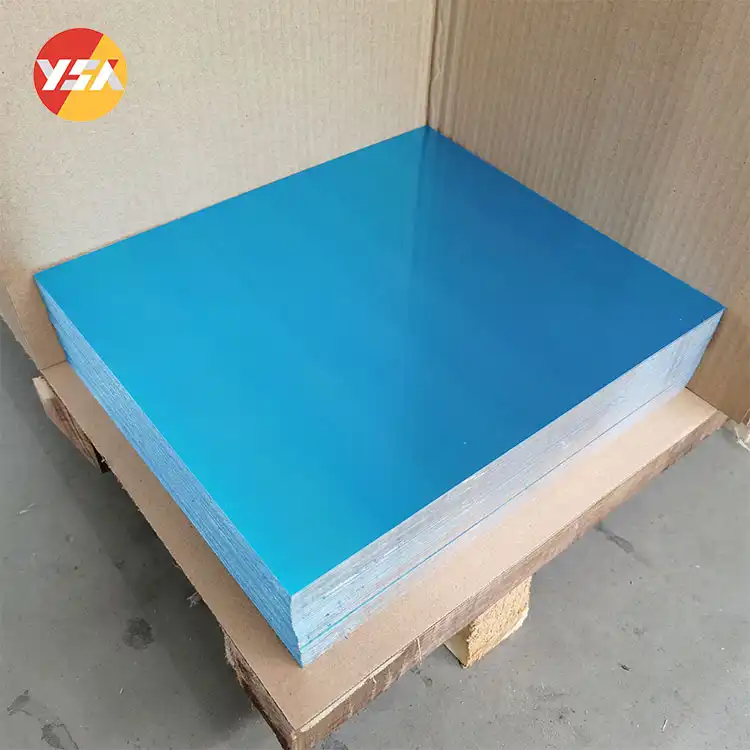

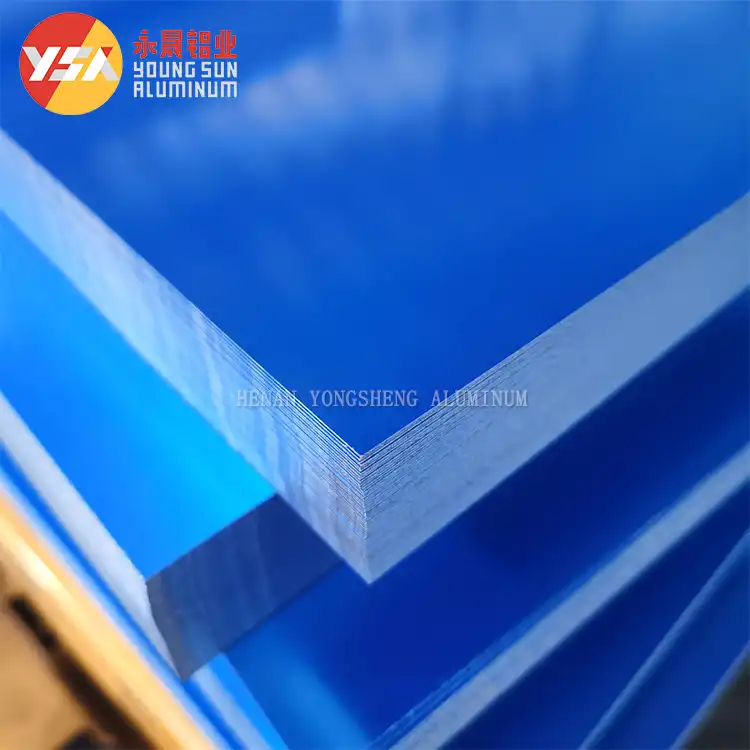

Thin Aluminum Sheet Introduction

A thin aluminum sheet refers to a flat and lightweight piece of aluminum with a thickness typically ranging from 0.1 mm to 6.0 mm. It is characterized by its formability, corrosion resistance, and high strength-to-weight ratio. Thin aluminum sheet is commonly used in various industries such as aerospace, automotive, electronics, packaging, and construction. They offer advantages such as being lightweight, easily shaped, and cost-effective. These sheets find applications where weight reduction, versatility, and cost-efficiency are key considerations.

Alloy Type Called Thin Aluminum Sheet

| Alloy Type | Thickness (mm) | Density (g/cm³) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

| 1000 Series | 0.1 – 6.0 | 2.7 – 2.8 | 70 – 210 | 15 – 100 | 25 – 40 |

| 3000 Series | 0.1 – 6.0 | 2.7 – 2.8 | 110 – 250 | 55 – 215 | 20 – 30 |

| 5000 Series | 0.1 – 6.0 | 2.68 – 2.73 | 130 – 320 | 65 – 275 | 10 – 30 |

| 6000 Series | 0.1 – 6.0 | 2.7 – 2.8 | 170 – 310 | 55 – 275 | 10 – 30 |

| 7000 Series | 0.1 – 6.0 | 2.7 – 2.8 | 220 – 570 | 140 – 470 | 5 – 25 |

What is the Thin Aluminium Sheet Used for?

- Aluminum Cans: Thin aluminum sheets are extensively used in the production of beverage cans. The sheets are shaped and formed into cans for carbonated drinks, energy drinks, canned foods, and more.

- Foil Wraps and Containers: Thin aluminum sheets, commonly known as aluminum foil, are widely used for wrapping and storing food. They are used in households, restaurants, catering services, and food packaging industries.

- Electrical Conductors: Thin aluminum sheets are employed as electrical conductors in various applications. They are used in wiring, power transmission lines, electrical panels, and busbars due to aluminum’s excellent conductivity.

- Heat Sinks: Thin aluminum sheets with fins or extruded designs are utilized as heat sinks. They efficiently dissipate heat from electronic components, such as computer processors, LED lights, and power electronic devices.

- Roofing and Siding: Thin aluminum sheets are used in the construction industry for roofing and siding applications. They are lightweight, durable, and corrosion-resistant, making them suitable for residential and commercial buildings.

- Automotive Body Panels: Thin aluminum sheets are utilized in the automotive industry for body panels, such as hoods, doors, fenders, and trunk lids. Aluminum’s lightweight nature helps reduce vehicle weight, improve fuel efficiency, and enhance performance.

- Nameplates and Signage: Thin aluminum sheets are commonly used for manufacturing nameplates, labels, and signage. They can be engraved, stamped, or printed on to create durable and visually appealing identification and branding elements.

- Reflective Insulation: Thin aluminum sheets with reflective surfaces are used as insulation materials. They are employed in construction, HVAC systems, and packaging to reflect radiant heat and improve energy efficiency.

- Lithographic Plates: Thin aluminum sheets are used in the printing industry as lithographic plates. These plates are chemically treated to create a printable surface and are used in offset printing processes for high-quality commercial printing.

- Decorative Applications: Thin aluminum sheets are popular for decorative purposes in interior design, architecture, and artistic projects. They are used for wall coverings, ceiling tiles, decorative panels, and artistic installations.

Advantages of Thin Aluminum Sheet

- Lightweight Construction: Thin aluminum sheets are considerably lighter than metals like steel or copper, making them ideal for applications where reducing weight is critical. Industries such as aerospace, automotive, and transportation benefit from this advantage as it improves fuel efficiency and overall performance.

- Reflectivity: Aluminum exhibits high reflectivity for both heat and light. Thin aluminum sheets with reflective surfaces find use in applications like reflectors, lighting fixtures, solar panels, and reflective insulation. They effectively redirect and distribute light and heat.

- Formability and Versatility: Thin aluminum sheets possess excellent formability and can be easily shaped, bent, or molded into various configurations. This versatility makes them suitable for applications requiring intricate shapes, such as automotive body panels, architectural elements, and decorative accents.

- Aesthetically Pleasing: Aluminum has an inherently attractive appearance, and thin aluminum sheets can be enhanced with different surface treatments, coatings, or anodization to further enhance their visual appeal. They are commonly employed in architectural applications, interior design, and decorative elements.

Thin Aluminum Sheet VS Thick Aluminum Sheet

Thickness

Thin Aluminum Sheet: The usual thickness of thin aluminum sheets is between 0.2 and 1.0 mm. Their flexibility and light weight make molding and creating them simple.

Thick Aluminum Sheet: Generally speaking, aluminum sheets that have a thickness of 6.0 mm or more are regarded as thick. They offer strength and durability since they are more substantial and stiff.

Fortitude and Stiffness

Thin Aluminum Sheet: Compared to thicker sheets, thinner sheets are less robust and less rigid. They work well in situations where reducing weight is important but structural strength isn’t always necessary.

Thick Aluminum Sheet: Thick sheets are ideal for applications requiring load-bearing capacity and structural integrity since they have a higher strength and rigidity.

Applications

Thin Aluminum Sheet: Thin sheets find applications in industries such as electronics, packaging, automotive interiors, insulation, and decorative applications. They are commonly used for lightweight and flexible purposes.

Thick Aluminum Sheet: Thick sheets are employed in applications that require strength and durability. They are used in aerospace, marine, automotive exteriors, construction, industrial equipment, and heavy-duty structures.

Machinability

Thin Aluminum Sheet: Thin sheets are generally easier to machine due to their lower thickness. They can be cut, drilled, and formed with relative ease using standard machining techniques.

Thick Aluminum Sheet: Thick sheets may require more robust machining equipment and techniques due to their greater thickness. Machining thick sheets may involve more time and effort.

Cost

Thin Aluminum Sheet: Thin sheets are typically less expensive compared to thicker sheets. The lower material cost and reduced weight contribute to their affordability.

Thick Aluminum Sheet: Thick sheets are generally more expensive due to the larger quantity of aluminum required and the additional manufacturing processes involved.

Summary

Thin aluminum sheets are essential components in various industries due to their lightweight design, versatility, and favorable properties. They find applications in aerospace, automotive, electronics, construction, and packaging, offering advantages such as lightweight construction, corrosion resistance, thermal and electrical conductivity, formability, and recyclability. While thin sheets excel in weight reduction and flexibility, thicker aluminum sheets may provide higher strength and load-bearing capabilities. The choice between thin and thick aluminum sheets depends on specific application requirements and performance needs. Overall, thin aluminium sheets play a vital role in driving innovation, efficiency, and sustainability across industries.

FAQ

How thin can you get aluminum sheets?

Aluminum sheets can be manufactured to extremely thin dimensions, reaching thicknesses as low as 0.005 mm (5 microns) in specialized processes. However, such ultra-thin aluminum sheets are not commonly available and require specialized manufacturing techniques.

How strong is 3mm aluminum plate?

The strength of a 3mm aluminum plate can vary depending on the specific alloy and temper. Generally, aluminum has a high strength-to-weight ratio, and a 3mm aluminum plate can provide sufficient strength for various applications. The exact strength characteristics depend on factors such as the alloy composition, heat treatment, and the intended use of the plate.

What is the thinnest sheet metal you can buy?

The thinnest sheet metal available commercially can be as thin as 0.001 inches (0.0254 mm) or even thinner. These extremely thin sheet metals are typically used in specialized applications, such as electronics, where precision and flexibility are crucial.

What is the cheapest type of aluminum sheet?

The cost of aluminum sheets can vary depending on factors such as alloy composition, thickness, and market conditions. Generally, pure aluminum sheets (1000 series) tend to be the least expensive due to their lower alloying elements. However, prices can fluctuate, and other factors such as sheet size and quantity also affect the overall cost.

What is lightweight aluminum?

Lightweight aluminum refers to aluminum alloys that have been specifically designed to have reduced weight while keeping strength and other desirable characteristics. These alloys mainly have a lower density compared to other metals, making them attractive for uses that prioritize weight reduction, such as aerospace, automotive, and transportation industries. Lightweight aluminum alloys can help enhance fuel efficiency, increase payload capacity, and enhance comprehensive performance.