Einführung

In the pharmaceutical industry, ensuring the safety, efficacy, and stability of medications is paramount. One material that has become indispensable in achieving these goals is aluminum foil, particularly the 8079 Aluminiumfolie grade. This specialized foil offers a range of favorable properties that make it ideal for pharmaceutical packaging and other applications. Let’s explore the uses and benefits of 8079 aluminum foil in the pharmaceutical sector!

What is 8079 Aluminum Foil?

Composition and Properties:

8079 aluminum foil is an aluminum alloy that is specifically designed to meet demanding requirements in packaging. It is characterized by its excellent barrier properties, mechanical strength, and corrosion resistance, which are essential for protecting sensitive pharmaceutical products.

Key Properties of 8079 Aluminum Foil

1. Excellent Barrier Performance:

– 8079 aluminum foil provides a robust barrier against moisture, light, and oxygen. This is crucial for protecting drugs from degradation and ensuring their shelf life is maximized.

2. High Mechanical Strength:

– The foil possesses high tensile strength, which helps maintain structural integrity during packaging, transportation, and handling.

3. Corrosion Resistance:

– This foil is resistant to various corrosive substances and environmental conditions, enhancing the safety of the pharmaceuticals it protects.

4. Formability and Ductility:

– 8079 aluminum can be easily formed into various shapes and sizes, allowing for versatile packaging solutions tailored to specific pharmaceutical products.

5. Lightweight:

– Despite its strength, aluminum foil is lightweight, making it cost-effective for shipping and reducing overall transportation costs.

Applications in Pharmaceuticals

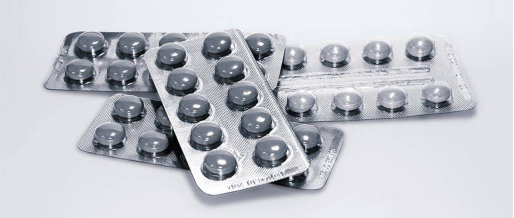

1. Blister Packaging:

– One of the most common applications of 8079 aluminum foil is in blister packs for tablets and capsules. The foil acts as a barrier, protecting the contents from moisture and air, thereby ensuring longer shelf life and maintaining potency.

2. Pouches and Bags:

– 8079 aluminum foil is often used in the manufacture of pouches for powdered medication, granules, or other solid forms. The foil provides a hermetic seal, preventing contamination and preserving the quality of the contents.

3. Laminated Products:

– This foil is frequently used as part of multi-layer films in pharmaceutical applications. When laminated with other materials, it enhances the barrier properties of the packaging, providing even greater protection.

4. Strip Packaging:

– Strip packaging for single-dose medications can utilize 8079 aluminum foil to create an effective seal that maintains product quality while allowing easy access for patients.

5. Secondary Packaging:

– The strength and flexibility of 8079 aluminum foil make it suitable for use in tertiary packaging solutions, ensuring additional protection during transportation and storage.

Advantages of Using 8079 Aluminum Foil

1. Enhanced Shelf Life:

– The excellent barrier properties help in maintaining the stability and shelf life of pharmaceuticals, reducing waste and increasing reliability for both manufacturers and consumers.

2. Safety and Compliance:

– Using high-quality materials like 8079 aluminum foil aligns with international safety standards and regulatory requirements, ensuring compliance in pharmaceutical packaging.

3. Customization:

– 8079 aluminum foil can be easily customized in terms of thickness, dimensions, and printing, enabling pharmaceutical companies to create branded packaging that stands out.

4. Sustainability:

– Aluminum is a recyclable material, and using aluminum foil for packaging aligns with the growing trend toward sustainable practices in the pharmaceutical industry. Reducing waste through recyclable materials contributes to environmental conservation.

5. Cost-Effectiveness:

– The combination of protection, functionality, and lightweight nature of the foil contributes to overall cost savings in logistics and manufacturing processes.

Schlussfolgerung

The 8079 aluminum foil serves as a vital component in the pharmaceutical industry, providing durability, safety, and effective protection for medications. From blister packs to pouches and laminated products, its applications are diverse and tailored to meet the strict requirements of pharmaceutical packaging.

As the pharmaceutical industry continues to evolve, the demand for reliable and efficient packaging solutions will only grow. With its unique properties and significant advantages, 8079 aluminum foil is likely to remain an integral part of pharmaceutical packaging, ensuring that medications reach consumers in optimal condition.

Embracing the innovation and efficiency that 8079 aluminum foil brings will help pharmaceutical manufacturers enhance their product offerings while safeguarding the health and well-being of patients worldwide.