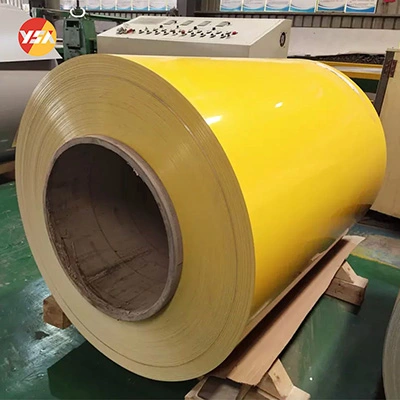

What Is Pre-Painted Aluminum Coil?

Pre-painted aluminum coil refers to the coloring treatment of the surface of aluminum alloy. Because the performance of aluminum alloy is very stable, it is not easy to be corroded. Generally, after special treatment, the surface layer can guarantee that it will not fade for at least 30 years, and because of its low density and high hardness, the unit It has the lightest volume and weight, and has become a new type of material in the latest door and window field. Compared with plastic steel, its biggest advantage is its incomparable firmness and changeable colors, and it will never face the “toxicity” that plastic steel is always questioned. Two words. Color-coated aluminum coils include 1000, 3000, 5000, 6000 series aluminum alloys, etc. Today, color-coated aluminum coils have become one of the most popular top-level decorative materials.

Color-coated aluminum coils can be divided into polyester-coated aluminum coils (PE) and fluorocarbon-coated aluminum coils (PVDF).

Polyester-coated aluminum coil (PE): It is an anti-UV ultraviolet coating. The polyester resin is a high molecular polymer containing ester bonds in the main chain as a monomer, and an alkyd resin is added. The ultraviolet absorber depends on the gloss. The degree can be divided into matte and high-gloss series. Especially suitable for interior decoration and advertising boards.

Fluorocarbon Coated Aluminum Coil (PVDF): It is made by mixing fluorocarbon resin with fluoroenyne as the basic monomer, pigment, alcohol ester solvent and additives. After high-temperature baking to form a film, the molecular structure of the coating is tight and has super weather resistance. Fluorocarbon coatings can be divided into traditional fluorocarbon coatings and nano-fluorocarbon coatings according to the surface film formation structure. It is especially suitable for the decoration and display of indoor and outdoor decoration in public places, commercial chains, exhibition advertisements, etc. This article will focus on introducing you the characteristics, application scenarios, suppliers of pre-painted aluminum coils and the unique advantages of Yongsheng pre-painted aluminum coils.

What Are The Features Of PE Color-Coated Aluminum Coils?

The polyester coating formed on the surface of the aluminum plate after repeated baking can form a strong film adhesion. It can endow colorful aluminum products with rich colors, good gloss and smoothness, as well as superior texture and hand feeling, and can also increase the sense of layering and three-dimensionality. It can protect objects from ultraviolet rays, wind, rain, frost, and snow; the coating can protect from the effects of temperature differences, freeze-thaw cycles, corrosive gases, and microorganisms. Especially suitable for interior decoration and advertising display boards.

What Are The Features Of PVDF Color-Coated Aluminum Coils?

PVDF color-coated aluminum coil has higher rigidity and pressure-bearing capacity than similar PTFE, but less lubricity and electrical insulation. Its working temperature is between -60°C and +150°C. PVDF is stable to chlorides, bromides and energy rays. As a decorative material, it has the following incomparable advantages of other products: uniform color, smooth and bright, strong adhesion, durable, acid and alkali resistance, corrosion resistance, weathering resistance, decay resistance, friction resistance, ultraviolet radiation resistance, and strong weather resistance.

1 Flatness:

As with color-coated galvanized steel sheets, there is no composite high-temperature indentation on the surface. No residual stress and no deformation after shearing.

2 Decorative:

Painted aluminum coils with wood grain and stone grain, with realistic physical texture and fresh natural beauty. The pattern can be made at will, giving customers a wide range of personality choices, enriching the humanistic connotation of the product, and giving people more aesthetic enjoyment.

3 Weather resistance:

The pattern of baking paint, which is made by coating and baking at high temperature, such as color galvanized sheet, has high gloss retention, good color stability, and small color change. Polyester paint has a 10-year warranty, and fluorocarbon paint has a 20-year warranty.

4 Mechanical:

Select high-quality aluminum, plastic, adhesive, and adopt advanced composite technology. The color aluminum coil has the bending strength and bending strength required by the decorative board. Four seasons, changes in wind pressure, temperature, humidity and other factors will not cause bending, deformation, expansion, etc.

5 Environmental protection:

The color aluminum coil can resist the corrosion of saline alkali acid rain, it will not corrode itself, will not produce toxic bacteria, will not release any toxic gas, will not cause corrosion to the keel and fixing parts, and is flame retardant. According to national regulations, no lower than B1 level.

What Is A Fluorocarbon-Coated Aluminum Coil Used For?

1. Architectural decoration design industry: production and manufacture of roof panels, roof panels, building curtain wall panels, interior wall decorative panels, ceiling panels, honeycomb paperboards, heat insulation panels, electric rolling doors, roof wave panels, fireproof panels, aluminum ceilings, shutters, Building decoration materials such as rolling shutter doors, garage doors, awnings, and gutters. Such as 1100 aluminum coils, 3003 aluminum coils, 3004 aluminum coils, 3105 aluminum coils, 5005 aluminum coils, 5052 aluminum coils, 6061 aluminum coils, etc. are all commonly used grades in the construction industry.

2.Food packaging industry: manufacturing food cans without pressure, food cans with pressure, can lids, corks, lids, bottle caps, food packaging boxes, sealed bags of various food packaging materials, etc. For example, 3003 aluminum coils, 1100 aluminum coils, and 5052 Aluminium-Spulen are commonly used brands for packaging.

3.Electronic and electrical industry: production and manufacture of central air-conditioning control panels, automatic washing machine control panels, refrigerator control panels, kitchen cabinet control panels, various digital fast printing electronic equipment casings, solar reflectors, lighting, furniture and other home appliance materials, Packaging and printing industry: manufacturing PS, CTP, UV-CTP printing plate making. Commonly used 1100 aluminum coils, 3003 aluminum coils, 5052 aluminum coils, 6061 aluminum coils, usw.

4.Road transportation industry: production and manufacture of van truck casings and inner cavities, automobile body panels, train carriage panels, ship interior panels, signboards for reliable traffic facilities, advertising bulletin boards, and luggage and leather goods. Commonly used aluminum coils include 3003 aluminum coils, 5052 aluminum coils, 6061 aluminum coils, etc.

Pre-painted Aluminum Coil Supplier-Yongsheng

Pre-painted aluminum coil refers to the aluminum coil that has been painted and colored by cleaning, chrome plating, rolling paint of various colors, baking, etc. Yongsheng can provide different types of paints such as PE/PVDF/HDPE/FEVE. Color options include RAL color, wood grain, stone grain, embossing, and can be customized according to customer requirements.

Its advantages are:

1.The temperature resistance is good

The melting point of aluminum is 660 degrees, and the general temperature does not reach its melting point.

2.Environmental protection

Not easy to turn yellow, using chromium-free treatment liquid to make up for the defects of easy discoloration of the laminating board; the roller paint contains active chemical molecules, which promotes the formation of a protective layer on the surface of the material. Active chemical molecules are stable and easy to recycle, meeting environmental requirements.

3.Corrosion resistance

Because of its tight surface oxide film, it has strong adhesion, oxidation resistance, acid resistance, alkali resistance, corrosion resistance, decay resistance and UV resistance.

4.Color uniform, long-lasting, its color is even and delicate

Soft and colorful, avoiding the individual chromatic aberration of traditional spraying, no matter how large the ceiling, its color and color are consistent. Lasting and new.

5.Rigid joint, the strength of the board is extremely high.

Rigid and tough combination, free to cut, slit, arc, balance, drilling, joint fixation and edge compression molding.