Flugzeugaluminiumblech

Legierung: 2024 2017 7075 7475 7050 5A06 5052 6061 6082, etc

Temperament: O, H14, H22, H32, T4, T6, T8, etc

Die Dicke: 0.2-350mm, customized

MOQ: 1 Tonne

Standard: ASTMB209, EN573-1S, usw.

Lieferzeiten: 7-25 Tage nach Auftragsbestätigung

Produkt-Einführung

Aircraft aluminum sheets have good mechanical and processing properties, good flexibility following solution treatment, and excellent heat treatment strengthening effects. They often have high strength and toughness below 150°C (or even higher), making them ideal aviation structural materials. The aviation sector mostly uses it for design and manufacturing purposes.

Aluminum alloys used in aircraft structures are mostly high-strength 2 series (2024, 2017, 2A12, etc.) and ultra-high-strength 7 series (7075, 7475, 7050, 7A04, etc.), with some 5 series (5A06, 5052, 5086, etc.), 6 series (6061, 6082, etc.) and a tiny number of other series aluminum materials.

Produktspezifikationen

| Name |

Flugzeugaluminiumblech

|

| Legierung | 2000 series, 7000 series, 5000 series, 6000 series, etc |

| Temperament | H14, H22, H32, T3, T4, T8, T651, etc |

| Dicke | 0.2-350mm |

| Breite | 500-2300mm |

| Länge | Kundenspezifisch |

| Verpackung | Wooden pallet, wooden box |

| MOQ | 1 Tonne |

| Muster | Kostenlos |

| Lieferfrist | 7-25 Tage nach Auftragsbestätigung |

| Normen | GB/T 33227-2016、JIS H4000、ASTM B209、EN 485 |

| Preis Konditionen | FOB, CIF, CFR, CNF, usw. |

Common Aircraft Aluminum Sheet

2024: This alloy is known for its high strength-to-weight ratio and excellent fatigue resistance. It is commonly used on aircraft structural components such as wing and fuselage skins, bulkheads and wing ribs.

6061: This alloy has good corrosion resistance and moderate strength. It is commonly used in aircraft parts that require both structural strength and machinability, such as aircraft accessories, brackets and panels.

7075: This alloy has excellent strength and is often used in applications requiring high strength and hardness. It is used in areas such as aircraft wing spars and structural parts that need to withstand high loads.

5052: This alloy has good corrosion resistance, formability and weldability. Used for aircraft fuel tanks, fuel tanks and other structural components that need to withstand harsh environments.

7475: This alloy is known for its high strength and excellent fracture toughness. It is commonly used in aerospace applications including aircraft wing skins and structural components.

7050: This alloy has high strength and good resistance to stress corrosion cracking. It is commonly used in aircraft wing structures, fuselage frames and bulkheads.

Produktanwendungen

2024 aviation aluminum sheet is used for aircraft structural parts. 2048 aviation aluminum sheet is mainly used to manufacture aerospace vehicle structural parts and weapon structural parts. 2218 is mainly used for aircraft engine and diesel engine pistons, aircraft engine cylinder heads, jet engine impellers and compressor rings. 2219 is used in space rocket welding oxidizer tank, supersonic aircraft skin and structural parts.

7049 is used for aircraft and missile parts, such as landing gear hydraulic cylinders and extrusions. 7050 aviation aluminum alloy is used in medium and thick plates, extrusions, free forgings and die forgings of aircraft structural parts. 7178 aviation aluminum sheet is used to manufacture parts of aerospace vehicles that require high compressive yield strength. 7475 aircraft aluminum sheets is used for fuselage plates, wing frames, stringers, etc. 7A04 is used for aircraft skins, screws, and stress-bearing components such as beam stringers, bulkheads, wing ribs, and landing gear.

Aircraft Aluminum Sheets Advantages

1. Superior strength and compact construction compared to mild steel.

2. Improved plasticity after solid solution treatment and effective heat treatment for strengthening.

3. Good mechanical qualities: Strong temperature: As the temperature rises, the strength of the alloy drops, but it remains strong at room temperature; Low temperature: The alloy offers excellent low-temperature strength and toughness. The alloy’s strength and hardness remain high in liquid nitrogen at -196°C.

4. It has strong cutting performance under heat treatment strengthening and wear resistance.

5. It has good anti-corrosion and anti-oxidation capabilities, although it is prone to stress corrosion cracking.

6. The welding performance is weak, and cracks are common during welding. It cannot be fusion welded, however it can be contact welded with a high pulse current.

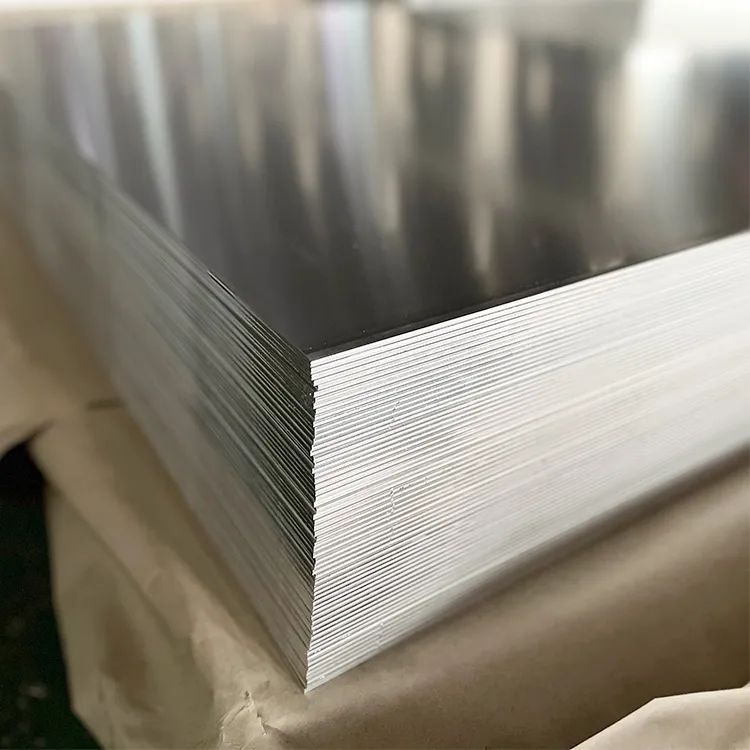

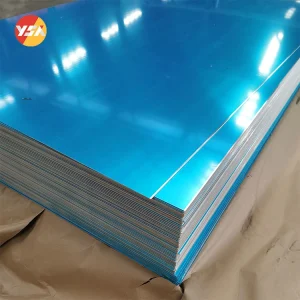

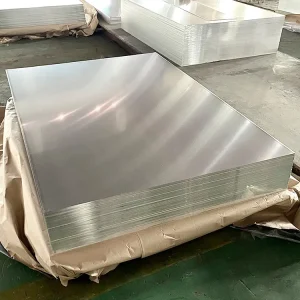

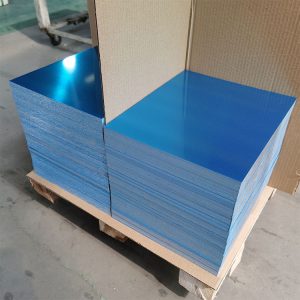

Product & Packaging Photos

Warum uns wählen

Yongsheng Aluminum ist ein führender Hersteller und Lieferant von Aluminiumprodukten in China mit 25 Jahren Exporterfahrung. Unsere hervorragende Produktqualität, unser Preis und unsere stets pünktliche Lieferung haben uns viele langfristige Partner eingebracht und uns weltweit einen guten Ruf eingebracht. Wir bieten Produktlösungen aus einer Hand für CC&DC Aluminiumprodukte.

Geschäftsabwicklungsprozesse