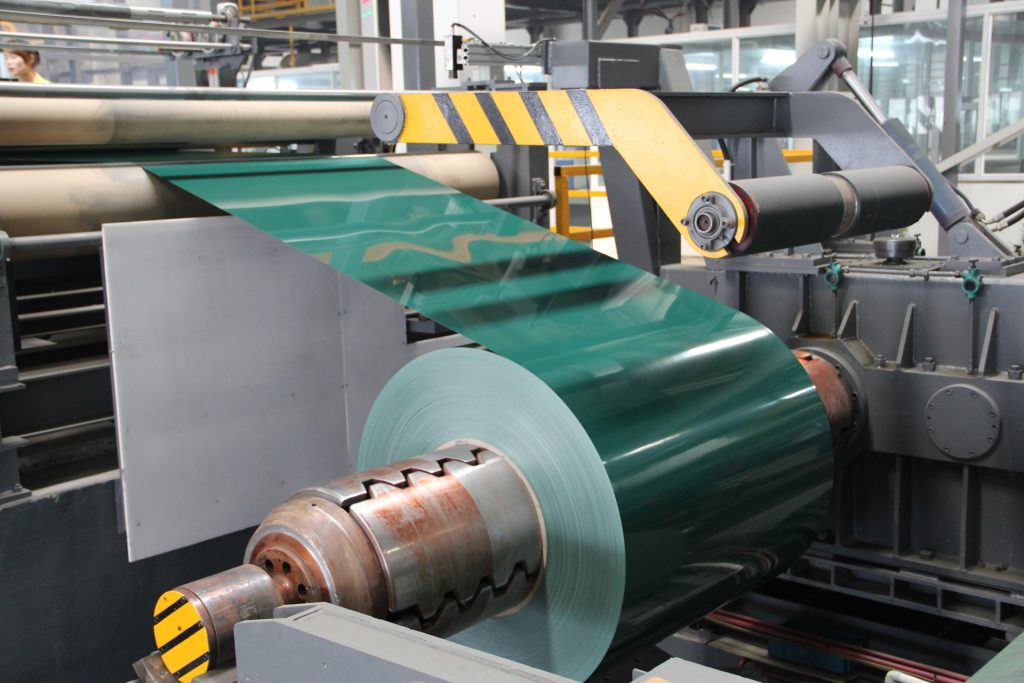

Roller coating is the most critical process in the entire aluminum sheet coil coating production line. The quality of the coating product, especially the apparent quality, directly affects the decorative effect of the product. Therefore, the first step is to grasp the common defects and their causes during the painting process.

The reasons for forming defects are multifaceted, with the following 5 common types:

1. Raw materials

Coatings and aluminum coils are the most influential factors in the coating process that can affect the quality of the coating. Due to color differences between batches of coatings, insufficient coating fineness and low coating rate, poor coordination between coatings and solvents, layering, etc., defects can directly affect the coating effect. The unevenness of the aluminum coil substrate, uneven film thickness, and poor edge deflection also directly affect product quality and overall use. Therefore, strict control should be exercised when selecting raw materials.

2. Equipment

The painting line requires the painting equipment to be in good condition, the painting equipment to operate smoothly, without horizontal or vertical shaking, and the painting rollers to be finely ground. The lateral runout of all rollers in the coating machine must be controlled within the allowable range, otherwise it will seriously affect the surface quality of the coating.

3. Craftsmanship

The painting process has a close relationship with the quality of painting, and it is required to control the relative linear speed ratio of the painting roller, paint lifting roller, measuring roller, and substrate within a certain range. According to different systems and the film thickness of painted products, a certain viscosity range should be set for the paint to ensure smooth painting and promote the improvement of product quality. The curing process of coatings and oven control must be controlled according to requirements and cannot be changed arbitrarily, otherwise it will seriously affect the coating production

4. Environment

Require the interior of the painting to be clean, dust-proof, insect proof, and ventilated to ensure that the surface quality of the painting is not contaminated. At the same time, the process conditions should be changed in a timely manner due to changes in temperature.

5. Human factors

The operator’s responsibility, proficiency in technology, and standardization of operation are key to achieving high-quality coating effects. Therefore, it is necessary to strengthen the training of operators and enable them to master the principles and key points of painting technology, strengthen their responsibility, and strictly follow the operating procedures to ensure high-quality painting products.

The above factors are interrelated and mutually influential. Sometimes the occurrence of a defect is related to multiple factors, and it must be analyzed and eliminated one by one.