Las planchas de aluminio se fabrican fundiendo primero el mineral de aluminio para extraer el aluminio metálico y, a continuación, fundiendo y moldeando el aluminio en planchas, seguidas de laminado, estirado y otros pasos de procesamiento. Los fundamentos de la producción de placas de aluminio se basan principalmente en la metalurgia y los procesos de procesamiento de metales. Debido a sus cualidades distintivas tales como bajo peso, alta resistencia, conductividad térmica, conductividad eléctrica, resistencia a la corrosión y plasticidad, las láminas de aluminio son ampliamente utilizadas en la industria aeroespacial, producción de vehículos, equipos electrónicos, construcción y áreas industriales. Este artículo le proporcionará algunas ideas sobre dónde conseguir chapas de aluminio de alta calidad:

Know The Aluminum Plates :

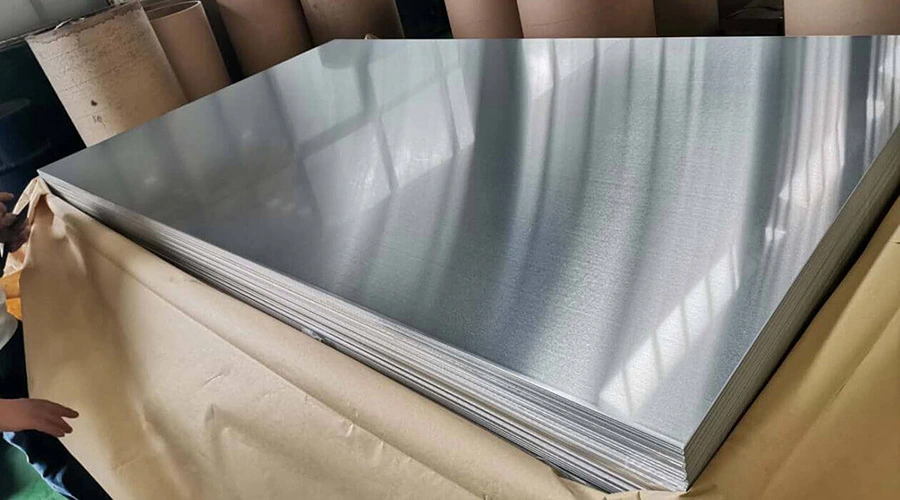

Las placas de aluminio son extremadamente duraderas y ligeras, lo que facilita su manipulación, transporte e instalación. Cuando el metal de aluminio se expone al aire, forma una barrera de oxidación que evita la oxidación y el deterioro. Gracias a sus propiedades de resistencia a la corrosión, las placas de aluminio son adecuadas para su uso en entornos duros o húmedos. Además, el aluminio tiene una excelente conductividad térmica y puede disipar eficazmente el calor en su superficie.

Types Of Aluminum Plates

Las chapas de aluminio se clasifican en 1-8 series. Cada serie tiene su propio conjunto de características y usos. Entre ellas, las placas de aluminio de las series 1000, 3000, 5000 y 6000 son las más utilizadas, mientras que las de las series 2000, 4000 y 7000 son poco comunes. El Aluminio serie 8000 is is primarily found in the form of aluminum foil sheets. We won’t go into too much detail here. Explain briefly several common aluminum alloy series:

1000 Series Aluminum Plate: With a minimum aluminum metal composition of 99%, this series is also known as the pure aluminum series. They are soft and pliable, making them excellent for deep sketching or spinning applications.

Placa de aluminio de la serie 2000: Serie de aleaciones de aluminio-cobre con una excelente resistencia a la fatiga. Se utilizan habitualmente en aplicaciones aeroespaciales.

3000 Series Aluminum Plate: Aluminum-manganese alloy series, with good formability and corrosion resistance. They are commonly used in the construction and automotive industries.

Placa de aluminio serie 4000: Compuesta principalmente de aluminio y silicio como principales elementos de aleación. Tiene una gran resistencia, especialmente a altas temperaturas, y aún puede mantener cierta resistencia. Es necesario utilizar procesos de soldadura y rellenos de aleación adecuados al soldar para garantizar la calidad y el rendimiento de la unión soldada.

5000 Series Aluminum Plate: Aluminum-magnesium alloy series with excellent corrosion resistance and weldability. They are commonly used in marine and transportation applications.

Placa de aluminio serie 6000: serie de aleación de magnesio y silicio, con buena conformabilidad, soldabilidad y resistencia a la corrosión. Se utilizan habitualmente en los sectores de la construcción y la automoción.

Placa de aluminio de la serie 7000: Serie de aleación de aluminio y zinc, de precio más elevado, con excelente resistencia y resistencia a la fatiga. Se utilizan habitualmente en aplicaciones aeroespaciales y de equipamiento deportivo.

- YSA Hot-sale Aluminum Sheet Series:

- Serie 1000

- Serie 3000

- Serie 5000

- Serie 6000

Assessing Your Specific Requirements:

A. Determine Aluminum Sheet Thickness:

Consider the intended use: Determine the intended application and mechanical load requirements to determine the appropriate plate aluminium thickness. Aluminium plates of different thicknesses are used in different fields. Thin aluminum sheet can be used for lighting fixtures, household appliances such as refrigerators or microwave ovens, elevators, and automobile decorative parts; thick aluminum plate can be used for aerospace aircraft, military supplies, ship decks, etc. Thicker aluminum plates generally provide greater strength and load-bearing capacity.

B. Deciding On Aluminum Sheet Size:

Tamaños estándar frente a tamaños personalizados: Determine si los tamaños de chapa estándar cumplen sus requisitos o si son necesarios tamaños personalizados. Los tamaños estándar son fáciles de conseguir y rentables, mientras que los tamaños personalizados ofrecen soluciones a medida.

Available Dimensions in the Market: Research the market to identify the range of plate dimensions available, such as length, width, and thickness options, the conventional size width and length of aluminum plates are 1050*2400mm, 1060*2400mm, 1100*2400mm, 1200*3800mm, and some ultra-wide aluminum plates such as widths above 1800mm can be customized and the length is within 8 meters. Common sizes of aluminum plates are:

- 4×8 aluminum sheet

- 1 8 aluminum sheets

- aluminum sheet 5mm

- 3 16 aluminum sheets

- 1 16 chapa de aluminio

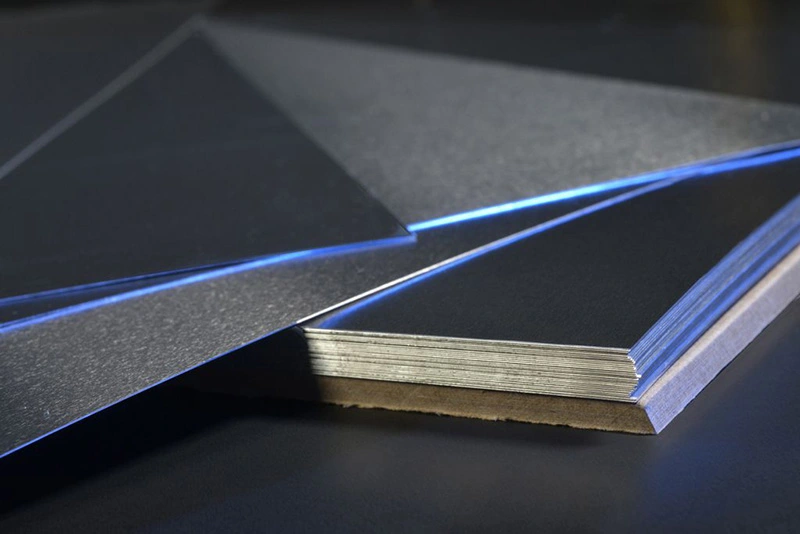

C. Opciones de acabado superficial:

Acabado de fresado: La opción más básica, las placas con acabado de fresado tienen un aspecto natural con una superficie lisa directamente del proceso de fabricación.

Acabado pulido: Con fines estéticos, los acabados pulidos proporcionan una superficie brillante y reflectante, a menudo utilizada en aplicaciones decorativas.

Anodized Finish: Anodizing alters the surface layer of the aluminum, enhancing its corrosion resistance and providing a range of color options. Anodized plates aluiminum are suitable when additional protection or a specific appearance is desired.

Selecting The Right Alloy:

Each series of aluminum alloys exhibits different properties based on its alloying elements. To determine the alloy, you must first understand the benefits and properties of each aluminum alloy series and evaluate the strength requirements, formability and corrosion resistance requirements of your application. For example, in terms of strength, the 6000 series contains strong alloying elements such as silicon, magnesium and zinc. It generally has higher strength than 5000 series aluminum alloys. It is also a widely used alloy series for industrial structural components. The 3000 series Al-Mn alloys have good corrosion resistance and weldability, and are commonly used in the manufacture of tanks, pressure vessels, and other applications. Although higher in strength than the 1000 series, they are still lower in strength compared to the 5000 and 6000 series aluminum alloys.

Assessing Aluminum Plate Quality:

Garantizar la calidad de las planchas de aluminio es crucial para el éxito de su proyecto. Tenga en cuenta los siguientes aspectos a la hora de evaluar la calidad de las planchas:

A. Certificación y normas:

ASTM Standards: Look for aluminum plates that comply with relevant ASTM (American Society for Testing and Materials) standards, ensuring they meet specific requirements for propiedades mecánicas, dimensions, and tolerances.

ISO Certification: Suppliers with ISO (International Organization for Standardization) certification demonstrate adherence to internationally recognized quality management standards, providing assurance of consistent product quality.

B. Pruebas e inspección de materiales:

- Appearance inspection: Visually inspect the plate for any surface defects, such as scratches, dents or irregularities, and observe whether the color of the aluminum plate is consistent, whether there are spots, bubbles or color differences, etc.

- Mechanical testing: Perform mechanical tests such as tensile strength, hardness, and elongation using equipment such as tensile testing machines, durometers, etc. to verify the mechanical properties of the material.

- Weather resistance test: Expose the aluminum plate to different environmental conditions such as high temperature, low temperature, humidity, etc., and observe whether corrosion or oxidation occurs on the surface of the aluminum plate.

- Dimensional inspection: Use measuring tools to check whether the dimensional parameters such as length, width, thickness and corner roundness of the aluminum plate meet your project requirements.

Evaluating Suppliers:

A. Búsqueda de proveedores reputados:

Check online networking platforms and industry forums for customer reviews and ratings of different suppliers, or seek advice from industry professionals or colleagues with experience working with aluminum panels to identify reliable suppliers.

B. Experiencia y conocimientos del proveedor:

Years in Business: Maybe you don’t understand this. There is actually no direct relationship between the number of years of establishment and the strength of the aluminum plate manufacturer. However, if the manufacturer has been in this industry for many years, then the professionalism of the aluminum plate factory must be much higher than that of a new factory.

Technical Support and Customer Service: The higher the production capacity and technical level of a supplier, the faster and more accurately it can complete the cutting work of various specifications and sizes. Good suppliers have strong enough technical strength and experience to provide customers with professional consultation and services and effectively solve any questions.

C. Solicitud de muestras y especificaciones:

Sample Availability: Requesting samples from prospective suppliers can help you understand product specifications in advance, including alloy composition, mechanical properties, dimensions and surface finish, etc.

Comparing Prices And Cost Factors:

A. Variación de precios entre proveedores:

Research the market to understand the price range for aluminum sheets, compare prices from different suppliers, and ask about the biggest discounts or special pricing suppliers can offer when ordering in large quantities or on a long-term basis. This will generally provide a price advantage for high-volume orders.

B. Factores adicionales de coste:

There are shipping and handling costs to consider, especially when sourcing aluminum panels from international suppliers. Freight, customization, loading and unloading and other costs must be taken into account and cannot be calculated blindly.

Considering Lead Times And Availability:

La disponibilidad puntual de chapas de aluminio es esencial para cumplir los plazos del proyecto. Evalúe la capacidad y los plazos de entrega del proveedor en función de los siguientes factores:

A. Capacidad de producción del proveedor:

When choosing an aluminum plate manufacturer, you can judge whether it is strong by looking at the size of the manufacturer. The more factories, the larger the area, and generally should not be underestimated. Another most effective method is to look at the inventory of aluminum plate manufacturers. Since aluminum plate factories generally operate on spot stock, the overall strength of the aluminum plate manufacturer can be judged from the quantity of inventory in the warehouse. The larger the inventory, the higher the trust level.

B. Plazos de envío y entrega:

Consider the distance between the supplier and your location. Local suppliers usually ship quickly, while international suppliers may have longer delivery times due to customs and logistics. If you need urgent delivery, be sure to negotiate with the supplier for expedited shipping, but certain additional costs will also be incurred.

Reviewing Warranty And Return Policies:

Conocer las políticas de garantía y devolución del proveedor garantiza la protección frente a defectos o problemas de rendimiento. Tenga en cuenta los siguientes factores:

A. Cobertura de la garantía del proveedor:

Be sure to clarify what the supplier’s warranty covers against manufacturing defects or any performance issues that arise from the use of aluminum panels. Determine the warranty period provided by the supplier to ensure it meets your project timeline.

B. Política de cambios y devoluciones:

Minimize risk by familiarizing yourself with your supplier’s return eligibility criteria and procedures and inquire about any potential fees and issues associated with returning products.

Placing Your Order:

A. Finalización de especificaciones y cantidades:

Aspectos como aleaciones, grosores, calibres, acabados aparentes y volúmenes son algunos de los que puede considerar especialmente importantes. Por ello, asegúrese de que los proveedores están informados al respecto.

B. Solicitud de presupuesto:

Detailed Quote with Breakdown: Reach out to the supplier and request a detailed quotation that includes the individual costs of aluminum plates, any additional services or customization fees, shipping costs, and applicable taxes. This breakdown will help you understand the total cost breakdown and make informed decisions.

Condiciones de pago: Infórmese sobre las condiciones de pago, como los métodos de pago aceptados, los requisitos de depósito y los plazos de pago. Aclare cualquier duda sobre el pago para evitar malentendidos.

C. Realización de la compra:

Opciones de pago: Elija un método de pago adecuado ofrecido por el proveedor, como transferencia bancaria, tarjeta de crédito o plataformas de pago online, y proceda con el proceso de pago según las condiciones acordadas.

Confirmación del acuse de recibo del pedido: Una vez efectuado el pago, solicite un acuse de pedido al proveedor para asegurarse de que su pedido ha sido recibido y está siendo procesado. Conserve este acuse de recibo para futuras consultas.

Taking Care Of Aluminum Plates:

A. Técnicas adecuadas de almacenamiento:

Store aluminum sheets in a dry environment and use protective covers or packaging to prevent corrosion and oxidation. When stacking aluminum panels, use partitions or spacers to avoid direct contact between panels and reduce the risk of scratches or damage. Handle and stack carefully to prevent dents or bends.

B. Consejos de limpieza y mantenimiento:

If there is dust buildup or corrosion on the surface of the aluminum plate, it is recommended to use a mild, non-abrasive cleaner or a special aluminum cleaner to clean the plate. When cleaning, please use a soft cloth, sponge or brush to avoid scratching the surface of the board.

PREGUNTAS FRECUENTES:

¿Cuál es el tipo de chapa de aluminio más barato?

Among the commonly used aluminum plate options, the most affordable option is usually aluminum alloy 3003. 3003 aluminum sheet is an aluminum-manganese alloy that is versatile and due to its wide availability and relatively low cost compared to other aluminum alloys, it Aluminum sheeting is generally considered the most economical option.

¿Es barato comprar aluminio?

El aluminio suele considerarse un material menos caro, sobre todo si se compara con otros metales como el acero o el titanio. Principalmente porque el aluminio abunda en la corteza terrestre, su extracción es barata y su transporte y transformación baratos. Sin embargo, el precio del aluminio se ve afectado por varios factores, como el tipo específico de aleación, la forma (como chapa, plancha o extrusión), el grosor, el tamaño y las condiciones del mercado. No puedo dar una respuesta concreta.

¿Cuál es la placa de aluminio más común?

The most common aluminium plates are usually from 1000 series aluminum alloy or 3000 series aluminum. Aluminum 1000 series, especially alloy 1100, is known for its high corrosion resistance and good formability, making it suitable for general purposes such as cookware, signage and decorative applications, which are more common in life. 3003 aluminum among the aluminum 3000 series is popular in applications such as building exterior walls, storage tanks, and auto parts because of its economical benefits, medium strength, and excellent processing properties.