In the world of luggage design, the material used significantly impacts the durability, weight, and overall performance of suitcases. Among the various materials available, 6061 aluminum alloy has emerged as a top choice for high-quality suitcases. Renowned for its strength, lightweight nature, and excellent corrosion resistance, 6061 aluminum is transforming the luggage industry. This article delves into the properties, benefits, and applications of 6061 aluminum alloy in suitcase manufacturing.

What is 6061 Aluminum Alloy?

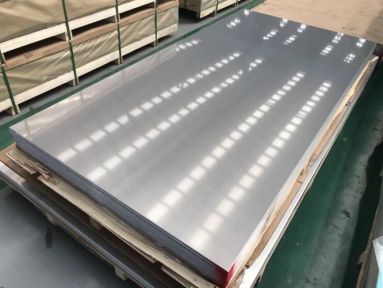

Aleación de aluminio 6061 is a versatile and widely used aluminum alloy that contains magnesium and silicon as its primary alloying elements. This combination gives 6061 its distinctive properties, making it suitable for a wide range of applications, including aerospace, automotive, and consumer goods like luggage.

Key Properties of 6061 Aluminum Alloy

1. High Strength-to-Weight Ratio: One of the standout features of 6061 aluminum alloy is its impressive strength-to-weight ratio. This characteristic allows manufacturers to produce robust suitcases that can withstand the rigors of travel while remaining lightweight and easy to carry.

2. Corrosion Resistance: 6061 aluminum exhibits excellent resistance to corrosion, which is vital for suitcases that may be exposed to various environmental conditions, such as moisture and aggressive substances. This corrosion resistance prolongs the lifespan of the suitcase, ensuring it remains functional and aesthetically pleasing.

3. Good Maquinabilidad: The alloy is known for its excellent machinability, allowing manufacturers to create complex shapes and designs without compromising structural integrity. This feature enables innovative suitcase designs that cater to modern traveler needs.

4. Weldability: 6061 aluminum can be easily welded, making it suitable for constructing various components of a suitcase. This property facilitates repairs and modifications, enhancing the longevity of the luggage.

5. Versatility: 6061 aluminum can be treated with various finishes, such as anodizing or powder coating, to improve aesthetics and further enhance its protective properties against scratches and dents.

Advantages of Using 6061 Aluminum in Suitcase Manufacturing

1. Durability: The inherent strength of 6061 aluminum allows for the creation of suitcases that can handle the rigors of travel, including rough handling during flights and road trips. This durability ensures that the suitcase can endure impact and maintain its shape over time.

2. Lightweight Design: With growing concerns over airline weight restrictions, the lightweight nature of 6061 aluminum is a significant advantage. Travelers can pack more essentials into lightweight suitcases without exceeding weight limits, making travel more convenient.

3. Stylish Appearance: Aluminum suitcases made from 6061 alloy have a modern and sleek appearance that appeals to many consumers. The ability to anodize or powder coat the aluminum adds aesthetic value, allowing for a range of colors and finishes to meet various design preferences.

4. Environmental Benefits: Aluminum is a recyclable material, and using 6061 alloy supports environmental sustainability. Manufacturers can create luggage that not only performs well but also minimizes environmental impact.

5. Cost-Effectiveness: While the initial cost of aluminum suitcases might be higher than traditional materials, the durability and longevity of 6061 aluminum often make it a more cost-effective choice in the long run. Users benefit from fewer replacements and repairs.

Applications in Suitcase Design

6061 aluminum is used in various components of suitcases, including:

– Shells: The outer shell of hard-sided suitcases often utilizes 6061 aluminum for its strength and lightweight properties, creating protective barriers for baggage.

– Frames and Supports: Internal frames that provide structure and support to suitcases benefit from the strength of 6061 aluminum, enhancing overall stability.

– Handles and Wheels: Manufacturing handles and wheels from 6061 aluminum contributes to the suitcase’s robustness and ease of maneuverability.

– Zippers and Closures: The alloy can also be used in durable zippers and closures, aiding in security and ease of use.

Conclusión

6061 aluminum alloy is an excellent choice for suitcase manufacturing, combining strength, lightweight design, and corrosion resistance. As travelers increasingly seek durable and stylish luggage options, the benefits of 6061 aluminum become even more apparent. Its versatility allows for innovative designs that cater to the needs of modern consumers, making it a material of choice in the competitive luggage market. Whether for frequent flyers or casual travelers, suitcases made from 6061 aluminum are poised to offer superior performance and longevity, ensuring that personal belongings remain safe and secure during every journey.