¿Qué es la 6061 T6 Aluminum?

6061 t6 aluminum is a popular alloy known for its excellent combination of strength, durability, and versatility. It belongs to the 6000 series aluminum alloys and is composed primarily of aluminum, magnesium, and silicon. The “T6” temper designation signifies that the material has been solution heat-treated and artificially aged, resulting in improved mechanical properties. 6061 t6 offers high tensile and yield strength, good formability, and excellent corrosion resistance. It is widely used in various industries, including aerospace, automotive, construction, and marine applications, where its strength, lightweight nature, and resistance to corrosion are highly valued.

6061 T6 Aluminum Propiedades

6061-T6 aluminum is a popular alloy recognized for its exceptional blend of physical, chemical, and mechanical characteristics. In terms of its physical attributes, it possesses a relatively low density of 2.70 g/cm³, rendering it lightweight. The alloy demonstrates notable resistance to corrosion, particularly in environments exposed to seawater or industrial chemicals. Additionally, it exhibits high electrical and thermal conductivity. In the realm of mechanical properties, 6061-T6 aluminum offers impressive strength, boasting a tensile strength of 276 MPa and a yield strength of 240 MPa. It possesses favorable formability and workability, enabling various fabrication processes such as bending, welding, and machining. Furthermore, it showcases remarkable fatigue resistance, capable of enduring repetitive stress cycles without failure. These exceptional properties establish 6061-T6 aluminum as a versatile material extensively utilized in diverse industries like aerospace, automotive, construction, and marine, where a combination of strength, corrosion resistance, and formability is of utmost importance.

6061 T6 Aluminum Ventajas

- High Strength: 6061-T6 aluminum is a strong and lightweight material with an outstanding strength-to-weight ratio. Its yield strength is 35,000 psi, while its tensile strength is 275 MPa (40,000 psi). Because of its great strength, it can be used in structural applications where strength is essential.

- Good Formability: 6061-T6 aluminum may be readily bent, curved, or formed into a variety of forms due to its good formability. Common procedures can be used to manufacture, weld, and join it, giving it versatility and ease of handling.

- Outstanding Weldability: Due to its great weldability, aluminum 6061-T6 can form sturdy and dependable joints. Numerous procedures, such as resistance welding and TIG (tungsten inert gas) and MIG (metal inert gas), can be used to weld it.

Alloy 6061 T6 Applications

- Aeroespacial: The alloy is utilized for constructing aircraft components such as fuselage frames, landing gear pillars, fuel tanks, and rotors.

- Automóvil: 6061-T6 aluminum finds application in car bodies, engine parts, wheels, and structural components for its strength and lightweight properties.

- Marina: It is employed in the marine industry for boat hulls, ship components, and other structures due to its corrosion resistance and durability.

- Bicycle Frames: The alloy is a popular choice for manufacturing bicycle frames, benefiting from its combination of strength and low weight.

- Construcción: 6061-T6 aluminum is used in building frames, doors, windows, ceilings, and other architectural structures that require strength and corrosion resistance.

- Electrical and Electronic: The alloy is well-suited for electrical enclosures, heat sinks, and components due to its electrical conductivity and thermal properties.

- Embalaje: It is employed in the production of cans, lids, bottles, and packaging foils for various industries like food, beverages, cosmetics, and pharmaceuticals.

- Machinery and Equipment: 6061-T6 aluminum is utilized in machinery parts, tooling, and equipment components due to its strength, machinability, and durability.

- Sporting Goods: The alloy is used in the production of sporting equipment such as bicycle frames, golf club heads, and lightweight gear.

- DIY and Hobbyist Projects: 6061-T6 aluminum is popular among DIY enthusiasts and hobbyists for various projects that require a strong and lightweight material.

6061 T6 Aluminum VS 7075

Fuerza

- 6061-T6 aluminum: It has a moderate strength level, providing a good balance of strength and weight.

- 7075 aluminum: It is significantly stronger than 6061-T6 aluminum, offering high tensile and yield strength.

Maquinabilidad

- 6061-T6 aluminum: It has good machinability and can be easily formed, welded, and fabricated using standard techniques.

- 7075 aluminum: It is harder to machine compared to 6061-T6 aluminum and may require specialized equipment and techniques.

Aplicaciones comunes

- Aluminio 6061-T6: It is commonly used in aerospace components, bicycle frames, automotive parts, marine equipment, and architectural structures.

- 7075 aluminum: It finds applications in aerospace and aircraft components, military equipment, high-performance bicycle frames, and structural parts subjected to heavy loads.

Temper Treatment Processing

This specific treatment involves a two-step process, starting with the heating of the alloy piece in a solution, followed by an ageing action.

In the first step, the alloy piece is immersed in a solution at a constant temperature of 980 °F (527 °C). It remains in the solution for one hour before being transferred to cold water. This initial hour allows the alloying elements in the aluminum to dissolve, while the rapid cooling in the water prevents the precipitation of individual alloying elements that would otherwise occur during gradual cooling.

The next step involves ageing the piece, which can be accomplished through various methods. Generally, this entails raising the temperature to approximately 350 °F (177 °C) and maintaining it for an additional 1-18 hours, with the exact duration depending on the shape, size, and intended application of the piece.

If there are additional designation digits and letters following “T6,” it indicates that the piece has undergone further treatments. These may include strain hardening (H1), strain hardening and annealing (H2), strain hardening and stabilization (H3), or strain hardening and painting/coating (H4).

Due to its exceptional tensile strength compared to other variations of the 6061 alloy, 6061-T6 is commonly employed in applications where achieving a high strength-to-weight ratio is crucial. Some examples include aircraft and aerospace components, bicycle frames, fishing reel parts, rifle components, vacuum chambers, and modeling products.

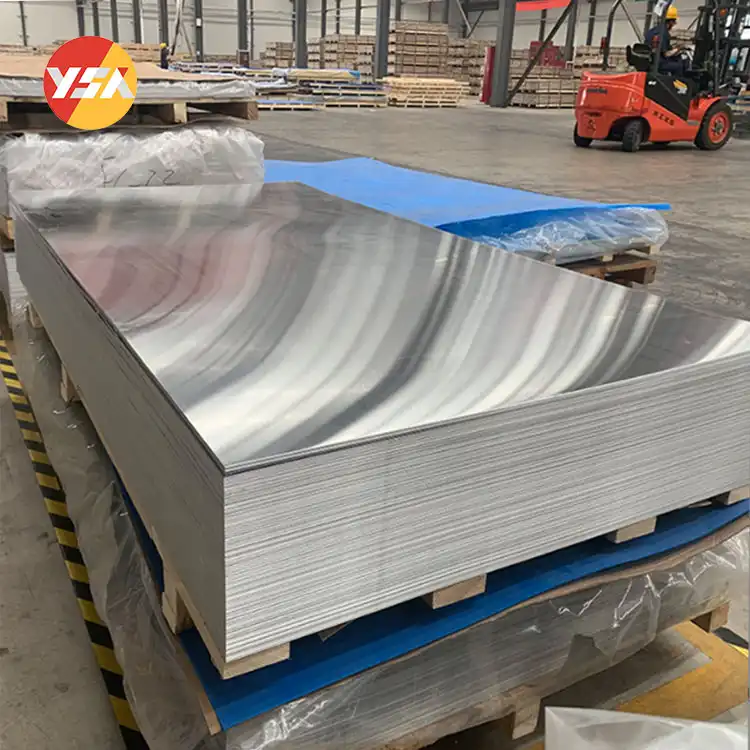

Henan Yongsheng 6061 T6 Aluminum

At Henan Yongsheng Aluminum, we specialize in the production of high-quality 6061-T6 aluminum, ensuring precision and efficiency at every step. Our factory maintains strict quality control measures throughout the manufacturing process, guaranteeing that our products consistently meet the highest industry standards. Moreover, we prioritize customer satisfaction by offering tailored solutions to meet specific requirements, be it dimensions, surface finishes, or other specifications. Our unwavering commitment to continuous improvement and innovation keeps us at the forefront of the market, allowing us to provide our customers with the latest advancements in 6061-T6 aluminum alloys. With a reliable supply chain and streamlined logistics, we ensure prompt delivery and exceptional customer service. Make us your preferred supplier and experience the advantages of our cutting-edge production capabilities, unwavering dedication to quality, and customer-centric approach.

Resumen

In summary, 6061 T6 aluminum is a highly versatile and easily workable alloy that offers excellent strength, corrosion resistance, and cost-effectiveness. Its compatibility with various fabrication methods, such as machining, welding, and bending, makes it a preferred choice for manufacturers seeking to create innovative and reliable products. The availability and affordability of 6061 T6 aluminum further contribute to its practicality. Its remarkable properties and capabilities have solidified its position as a vital material in numerous industries. As its utilization continues, 6061 T6 aluminum will continue to drive the development of strong, lightweight, and durable products for years to come.

PREGUNTAS FRECUENTES

The difference between 6061 and 6061 T6 aluminum.

The main difference between alu 6061 and alu 6061 t6 lies in their temper designation. 6061 is a general-purpose aluminum alloy, while 6061 t6 refers to a specific temper within the 6061 alloy. The “-T6” designation indicates that the material has undergone a heat treatment process, resulting in improved mechanical properties and increased strength compared to the base 6061 alloy.

Is 6061 T6 aluminum stronger than steel?

6061 t6 aluminum is not generally considered to be stronger than steel in terms of ultimate tensile strength. Steel typically has higher strength properties, especially in terms of its yield strength. However, 6061 t6 aluminum still offers a favorable strength-to-weight ratio, making it a popular choice in many applications where weight is a concern.

What is the best grade of aluminum?

The “best” grade of aluminum depends on the specific application and requirements. Different grades of aluminum offer different properties and characteristics. For example, 6061 aluminum is widely used for its strength and versatility, while 5052 aluminum is known for its excellent corrosion resistance. Other popular grades include 7075 for high strength applications and 5083 for marine applications. The best grade of aluminum will vary based on factors such as strength, corrosion resistance, formability, and cost considerations.

Is 6061 aluminum hard or soft?

6061 aluminum is considered to be a moderately hard alloy. It has a hardness of around 95 HB (Brinell Hardness), which is relatively low compared to some other aluminum alloys. However, it is important to note that the hardness of aluminum can be influenced by various factors such as temper, heat treatment, and alloy composition. The T6 temper of 6061 aluminum, which involves artificial aging, increases its hardness and strength compared to the base alloy.