Aluminum alloys in boat building has been playing a crucial role in the construction process. The use of aluminum offers numerous advantages, including their lightweight nature, corrosion resistance, and strength-to-weight ratio. In this comprehensive guide, we will delve into the properties of alloys of aluminum, explore the commonly used alloy series, and highlight their specific applications in boat building.

Properties of Aluminum Alloys

- Lightweight: Alloys of aluminum are significantly lighter than other commonly used metals in boat building, such as steel or copper. This characteristic helps reduce the overall weight of the vessel, resulting in increased speed, fuel efficiency, and improved handling.

- Corrosion Resistance: Alloys of aluminum possess natural corrosion resistance due to the formation of a protective oxide layer on their surface. This property enables boats constructed from aluminum it to withstand exposure to saltwater and other corrosive elements, minimizing maintenance requirements.

- Strength: While aluminum is inherently lightweight, it can be alloyed with other elements to enhance its strength. Different alloys of aluminum series, such as the 2000, 5000, and 6000 series, offer varying levels of strength, providing boat builders with options to match the specific requirements of their designs.

- Ductility: Alloys of aluminum exhibit excellent ductility, allowing them to be easily formed, shaped, and fabricated into complex boat structures. This property facilitates the construction of intricate designs and contributes to the versatility of aluminum in boat building.

Commonly Used Aluminum Alloy Series

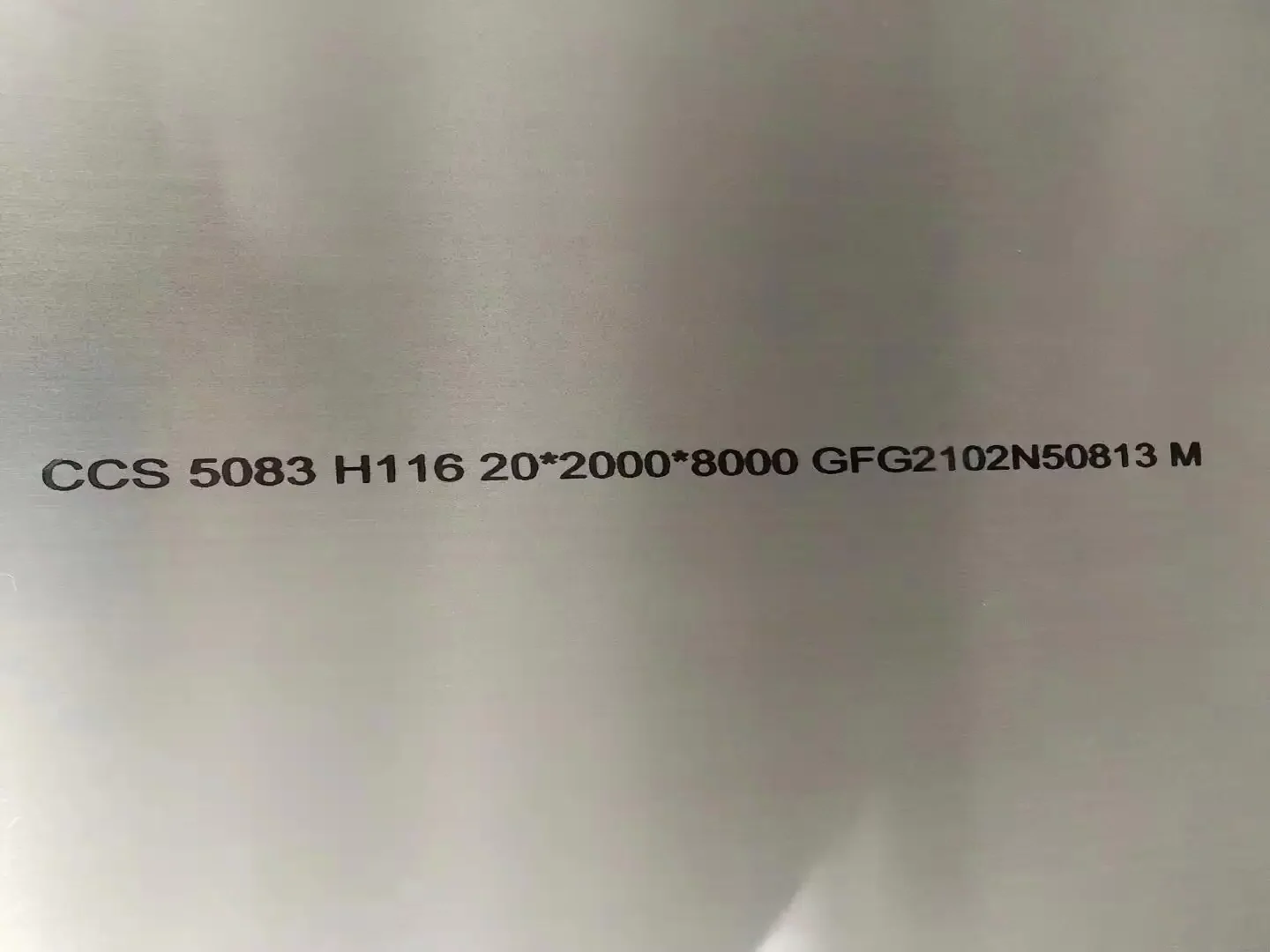

- 5000 Series Aluminum Alloys: The 5000 series aluminum alloys, including 5052 and 5083, are commonly used in boat building due to their excellent corrosion resistance and moderate strength. These alloys are often used for hulls, decks, and other structural components. Their formability makes them suitable for various boat designs.

- 6000 Series Aluminum Alloys: Alloys in the 6000 series, such as 6061 and 6082, offer a balance of strength, corrosion resistance, and weldability. They find extensive application in boat building, particularly for structural components like frames, masts, and railings. The 6000 series alloys provide good formability and can be easily machined.

- 7000 Series Aluminum Alloys: The 7000 series, particularly alloy 7075, is renowned for its high strength and excellent fatigue resistance. These alloys are commonly used in high-performance boats and racing yachts where strength and durability are paramount. The 7000 series alloys are utilized for keels, masts, and other critical load-bearing components.

- 2000 Series Aluminum Alloys: Alloys in the 2000 series, such as 2024 and 2014, are known for their exceptional strength-to-weight ratio. These alloys are favored in the aerospace industry and find application in high-speed boats and racing sailboats. The 2000 series alloys are used for structural components, including frames, supports, and fittings.

- 1000 Series Aluminum Alloys: The 1000 series aluminum alloys, specifically alloy 1100, are commercially pure and have excellent corrosion resistance. While they may not possess the same strength as other alloy series, they are often used in non-structural boat components like interior paneling, trim, and fittings.

- Aluminum-Lithium Alloys: Aluminum-lithium (Al-Li) alloys, such as alloy 8090, are gaining attention in the boat building industry. These alloys offer a significant reduction in weight compared to conventional aluminum alloys, making them attractive for high-performance racing boats and lightweight recreational vessels.

Specific Applications of Aluminum Alloys in Boat Building

- Hull Construction: Alloys of aluminum are widely used for constructing boat hulls due to their lightweight nature, corrosion resistance, and durability. The ability to resist the harsh marine environment makes aluminum alloy hulls a popular choice among boat builders.

- Decks and Superstructures: Alloys of aluminum are employed in building boat decks and superstructures due to their strength, corrosion resistance, and ease of fabrication. Aluminum decks and superstructures contribute to weight reduction without compromising structural integrity.

- Masts and Rigging: Alloys of aluminum find extensive use in the construction of masts and rigging systems for sailboats. The lightweight nature of aluminum masts improves the vessel’s performance by reducing weight aloft.

- Keels and Ballast: Alloys of aluminum, known for their high strength, are utilized in constructing keels and ballast systems. These components provide stability and balance to the boat, enhancing performance in sailing and racing.

- Structural Components: Aluminuim alloys are employed for various structural components in boats, including frames, supports, and railings. The strength and formability of aluminum alloys allow for the creation of robust and aesthetically pleasing structures.

- Fuel Tanks: Aluminuim alloys are a popular option for constructing fuel tanks owing to their corrosion resistance and compatibility with common fuels. Aluminum fuel tanks provide durability, longevity, and the ability to be custom-shaped to fit specific boat designs.

- Interior Components: Aluminuim alloys are used for interior components such as paneling, trim, and fittings. The corrosion resistance and ease of fabrication make aluminuim alloys an excellent choice for these uses, offering a sleek and modern appearance.

- Personal Watercraft: Aluminuim alloys are extensively used in the construction of small recreational boats and fishing boats. The lightweight nature of aluminuim alloys contributes to improved maneuverability, fuel efficiency, and durability.

Advantages of Using Aluminum Alloy for Boat Building

- Weldability: Aluminuim alloys used in boat building generally exhibit good weldability, allowing for efficient joining of structural components. Welding techniques such as MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) are commonly employed to create strong and durable welds, ensuring the integrity of the boat’s structure.

- Surface Treatments: To further enhance the corrosion resistance and aesthetics of aluminuim boats, various surface treatments can be applied. These include anodizing, which thickens the natural oxide layer, providing added protection, as well as powder coating or painting for decorative purposes.

- Customization and Design Flexibility: Aluminuim alloys offer boat builders significant design flexibility. They can be easily cut, bent, and formed into complex shapes, allowing for the creation of unique and customized boat designs. This flexibility enables boat builders to meet specific customer preferences and optimize the vessel’s performance.

- Environmental Sustainability: Aluminuim is a highly recyclable material, and the use of aluminum alloys in boat building aligns with environmental sustainability goals. Recycling aluminum requires significantly less energy compared to primary production, making it an eco-friendly choice for boat construction.

- Cost Considerations: While aluminum alloys offer numerous advantages, it’s important to consider the cost implications. Aluminuim alloys generally have a higher upfront cost compared to some other materials like fiberglass or wood. However, the long-term benefits such as low maintenance, durability, and fuel efficiency can offset the initial investment over the lifespan of the boat.

Summary

Aluminuim alloys have revolutionized the boat building sector, providing a extensive array of benefits in terms of strength, weight reduction, and resistance to corrosion. The multipurpose of aluminuim alloys enables their use in many kinds of boat elements such as hulls, decks, masts, and structural components. As the boat building industry progresses, aluminuim alloys will keep an necessary ingredient, driving advancements, and improving the effectiveness and longevity of boats.