The performance requirements of battery aluminum foil are very strict. It is not difficult to meet the requirements of several indicators, but it is difficult to meet all the requirements:

Melt mass

In the process of metal smelting, there will be certain gas, metal and waste metal inclusions in the melt, which will cause the finished product needle holes to exceed the standard, which is also an important reason for affecting the quality of the final aluminum foil. In order to ensure the quality of aluminum foil, melt purification is very important, the key is the process steps such as gas removal, slag removal and filtration process, generally control the hydrogen content index 0.1ml / 100 gAL.

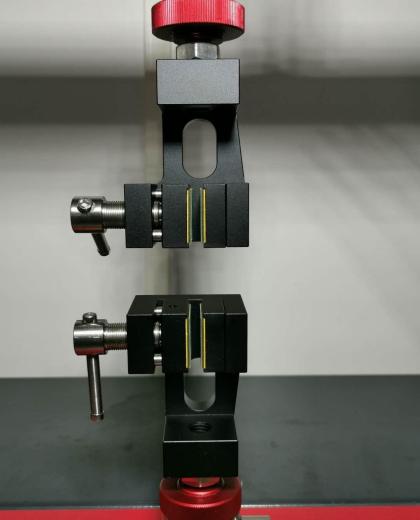

Plate control

Plate shape, also known as tension, is an important indicator of the smoothness of aluminum foil. In the aluminum processing industry, the online plate instrument is used for control, the principle is to use the plate instrument to feel the transverse force per unit area of aluminum foil, and feedback the tightness of aluminum foil. Battery manufacturers usually use offline plate detector to detect the shape of the plate, the principle is to use the corresponding tension flat aluminum foil, detect the difference between the horizontal position and the side of the product, called the collapse amount.

Thickness control

The thickness of aluminum foil for general batteries is required to be within ± 4%, while the aluminum foil mill is mainly controlled by the on-line thickness control system. Although some downstream battery manufacturers hope to control the thickness tolerance of battery aluminum foil within ± 2%, most of the equipment on the market cannot achieve such control precision. The factors affecting the thickness tolerance include the alloy composition, hydraulic system, roll roundness and bearing accuracy. Together, these factors limit the possibility of current technology to achieve more stringent thickness control.

Surface quality of Battery aluminum foil

Battery aluminum foil has extremely high requirements on the surface quality of aluminum foil, requiring uniform color, no serious stripe and color difference, no bump and drum line, no residual oil and foreign body pressure, no scratches and scratches and other defects. To ensure that the product meets this strict quality standard, the finished battery aluminum foil shall be tested for pinhole and surface defects.

Mechanical behavior

The tensile strength and elongation of aluminum foil for battery are the mechanical performance indicators that need to be paid attention to. The higher the tensile strength, the better, the elongation is within 5%, and the higher the better.

Surface wetting tension

This index is described by the mechanical unit “factor value” (i. e. n). Generally, users require the surface wetting tension at 30-32 dyn, and some sensitive materials have higher requirements on cause value.

End surface quality

That is, the cutting quality of the edge of the aluminum foil, the edge can not have V-type gap, burr, aluminum wire and other defects.