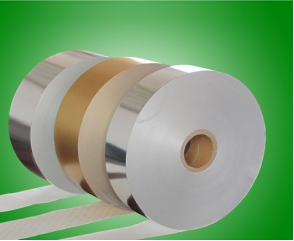

1235 papel de aluminio is a highly popular choice in various industries, especially in cigarette packaging, thanks to its exceptional characteristics. This article will explore the features, advantages, and diverse applications of 1235 aluminum foil in cigarette packaging, helping you understand the significance of this essential material.

Features of 1235 Aluminum Foil

1. Excellent Barrier Properties

1235 aluminum foil boasts outstanding barrier performance, effectively preventing moisture, oxygen, and light from penetrating. This is crucial for maintaining the freshness and flavor of cigarettes, as prolonged exposure to external environments can negatively impact their quality. Proper packaging with 1235 aluminum foil can significantly extend shelf life, ensuring consumers enjoy the best possible taste.

2. Good Formability

The foil exhibits excellent formability, making it easy to process into various shapes and sizes needed for cigarette packaging. This adaptability allows manufacturers to meet diverse product design requirements while ensuring that the packaging looks attractive and professional, thereby capturing consumers’ attention.

3. Lightweight

Being a low-density material, 1235 aluminum foil is lightweight, which enhances efficiency in transportation and storage. This is particularly beneficial for mass production of cigarette packaging, as lighter materials can help reduce shipping costs and improve overall operational efficiency.

4. Printability

The surface of 1235 aluminum foil is ideal for printing, allowing brands to showcase various designs that highlight their identity. Eye-catching colors, intricate patterns, and clear text can be printed on the foil, enhancing the product’s appeal and conveying the brand’s story and values effectively.

Advantages of 1235 Aluminum Foil

– Eco-Friendliness

Aluminum is a recyclable material, aligning with modern sustainability trends. By opting for 1235 aluminum, brands can cater to environmentally conscious consumers and promote their commitment to sustainable practices, helping to build a positive brand image.

– Anti-Counterfeiting Features

1235 aluminum foil can be combined with various anti-counterfeiting technologies, bolstering product security. Unique packaging designs can instill greater trust among consumers, helping to mitigate the risk of counterfeit products entering the market.

– Corrosion Resistance

The foil’s corrosion-resistant properties ensure stability and reliability during storage and transport. This means that cigarettes packaged in 1235 aluminum can maintain their high quality even in humid or variable climate conditions, which is vital for delivering consistent, premium products.

Application Areas

1. Cigarette Packaging

1235 aluminum foil is primarily used for the inner and outer packaging of cigarettes, helping to keep them fresh and flavorful. For many premium cigarette brands, 1235 aluminum foil packaging is essential for ensuring quality during production, transport, and storage.

2. Food Packaging

In addition to cigarettes, 1235 aluminum is also widely used in various food packaging applications. Its superior barrier properties help preserve the taste and quality of food products, reducing waste and offering consumers more delicious options.

3. Pharmaceutical Packaging

In the pharmaceutical industry, 1235 aluminum plays a crucial role in protecting medications. The need for high safety and preservation standards makes aluminum foil an ideal choice, ensuring that active ingredients remain effective and uncontaminated.

Conclusión

In summary, 1235 aluminum foil stands out in cigarette packaging due to its exceptional properties. Its excellent barrier performance, good formability, lightweight nature, and printability make it a vital material for modern tobacco products. By protecting cigarette quality, extending shelf life, and enhancing brand image, 1235 aluminum foil not only improves consumer experiences but also promotes sustainable practices within the industry.