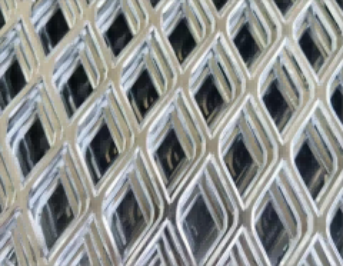

Aluminum mesh sheet is an advanced construction material known for its unique combination of lightweight, high strength, and excellent corrosion resistance. This versatility makes it widely used across various industries. Its distinctive structure and diverse applications have established it as an integral part of modern engineering and design. This article will delve into the properties, manufacturing processes, and wide-ranging applications of aluminum mesh sheet, as well as its future development prospects.

Properties of Aluminum mesh sheet

Aluminum mesh sheet is characterized by several notable advantages:

– Lightweight: Aluminum has a relatively low density, which significantly reduces the weight of aluminum mesh sheet. This feature not only facilitates transportation and installation but also lessens the overall burden on structures, thereby reducing construction costs. This is particularly beneficial in high-rise buildings and bridge projects where lightweight materials enhance safety and stability.

– High Strength: Despite its lightweight nature, aluminum mesh sheet exhibits excellent tensile strength and impact resistance. This high strength allows the mesh to maintain structural stability under various load conditions, making it ideal for use in construction and engineering applications.

– Corrosion Resistance: The surface of aluminum alloys naturally forms a dense oxide layer, greatly enhancing their resistance to corrosion. This property enables aluminum sheet mesh to withstand moisture and chemical exposure, ensuring long-term performance and reducing maintenance needs. This is especially valuable in marine and chemical facility applications.

– Good Ventilation: The perforated design of aluminum mesh sheet allows for excellent airflow, making it suitable for ventilation and drainage systems, as well as air purification devices. Its ventilation capabilities ensure proper air circulation, reducing pressure and temperature, which enhances the overall efficiency of systems.

Manufacturing Processes

The production of aluminum mesh sheet involves several stages, ensuring the quality and performance of the final product:

1. Raw Material Preparation: High-quality aluminum alloy materials are selected to meet international standards, laying the groundwork for the performance of the final product.

2. Cutting and Punching: The aluminum alloy sheets are accurately cut according to design specifications, followed by punching or laser cutting to create the desired mesh pattern. This process requires precision equipment to ensure standardized and consistent products.

3. Forming and Welding: The next step involves forming the aluminum sheets into the mesh structure and connecting various sections through welding, riveting, or other methods. Proper welding techniques are crucial to prevent material damage at the joints.

4. Surface Treatment: The surface of aluminum mesh sheet can undergo various treatments, such as anodizing, spraying, or coating. These processes not only improve durability and aesthetics but also enhance corrosion resistance.

Aplicaciones

The versatility of aluminum mesh sheet allows for a wide range of applications across multiple industries:

– Construction Industry: Aluminum mesh sheet is increasingly used in the facades, ceilings, partitions, and decorative panels of modern buildings. Its excellent ventilation, light transmission, and aesthetic appeal make it a popular choice for architects looking to create contemporary designs. This material enhances both the overall appearance and functionality of buildings.

– Transportation Infrastructure: In the construction of roads, bridges, and tunnels, aluminum mesh sheet is commonly used for safety barriers, fencing, and ventilation systems. Its strength and corrosion resistance ensure the longevity and safety of transportation facilities, solidifying its importance in civil engineering projects.

– Environmental Protection: Aluminum mesh sheet plays a crucial role in environmental applications, such as wastewater treatment and air filtration systems. Its permeability and resistance to corrosion make it effective in water treatment facilities and air purification devices, contributing to efficient environmental management.

– Home Decor: In residential design, aluminum mesh sheet is widely utilized for room dividers, screens, and decorative wall features. Its unique appearance and modern feel enhance the overall style of living spaces while providing flexibility and practicality for various interior designs.

– Aerospace: In the aerospace sector, the lightweight and high-strength properties of aluminum mesh sheet make it suitable for aircraft structural components, insulation layers, and other critical elements. These qualities not only ensure optimal performance but also improve fuel efficiency and reduce operating costs, aligning with core aircraft design goals.

Future Development Trends

With the advancement of technology and the increasing demand for high-performance construction materials, the application prospects for aluminum mesh sheet are quite promising. Future development trends will focus on:

– Lightweight and High Strength: Advances in materials science will enable the production of aluminum mesh sheet that achieves higher strength while remaining lightweight—especially important in high-end applications like aerospace.

– Smart Manufacturing: As smart manufacturing technologies progress, the production of aluminum mesh sheet will become more automated and precise, improving efficiency and product consistency.

– Eco-Friendliness: Aluminum’s recyclability and reusability align with the growing emphasis on environmental consciousness. This will continue to drive the usage of aluminum mesh sheet, especially in green building projects and sustainable development initiatives.

Conclusión

In summary, aluminum mesh sheet, with its unique properties and wide-ranging applications, has become an essential material in various sectors, including construction, transportation, and environmental protection. Its lightweight, high strength, and corrosion resistance allow it to meet modern engineering demands while promoting efficiency and sustainability. As technology continues to advance, the market potential and application fields for aluminum mesh sheet will expand, contributing positively to technological progress and environmental goals across industries.