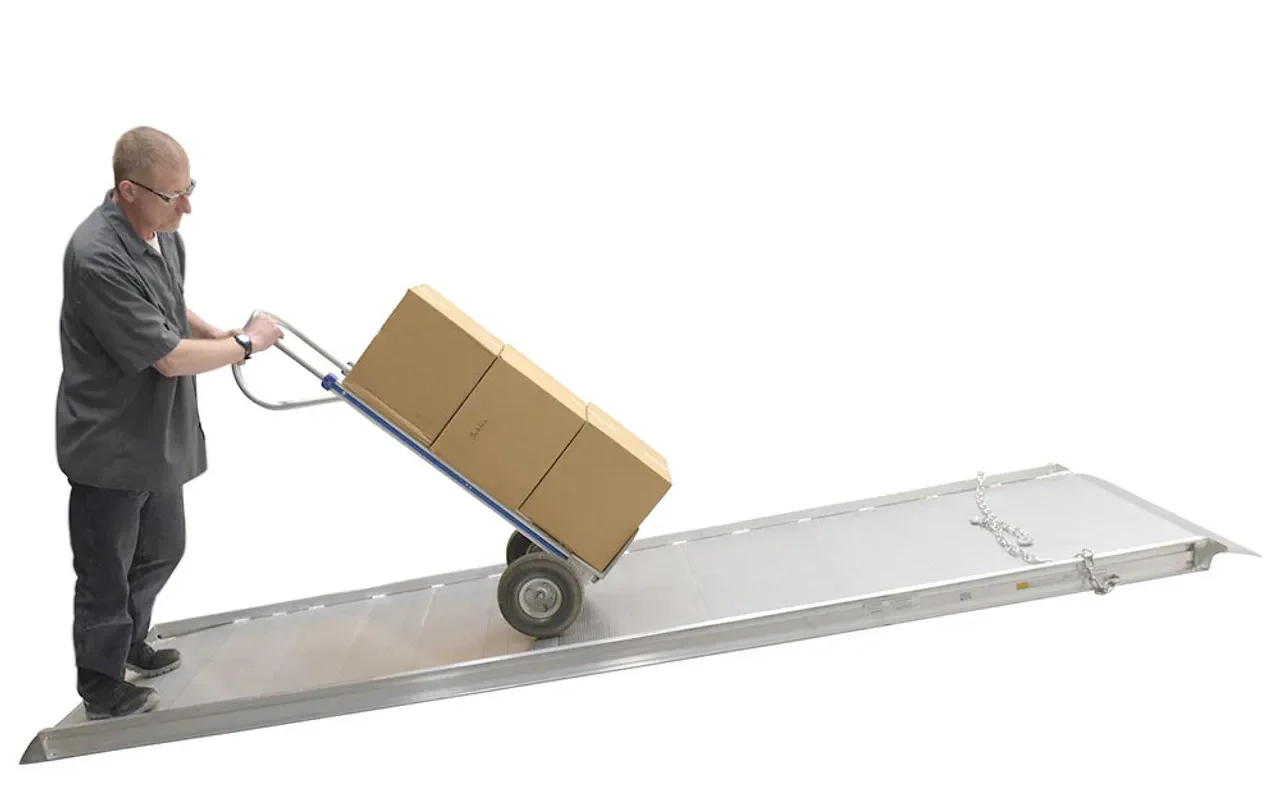

Aluminum ramps are commonly used in various settings, including residential, commercial, industrial, and recreational environments. They serve a wide range of purposes, such as wheelchair accessibility, loading and unloading equipment or vehicles, and facilitating movement between different levels or surfaces.

The lightweight nature of aluminum makes aluminum ramps easily portable and maneuverable, allowing for quick setup and adjustment as needed. This feature is particularly beneficial in situations where ramps need to be frequently relocated or stored when not in use.

Besides, embossed aluminum sheets can enhanced traction in various aluminum ramp applications, including residential, commercial, and industrial settings. The improved grip offered by embossed aluminum sheets ensures safety and stability for all users, including individuals with mobility challenges or those handling heavy equipment.

Why Choose Embossed Sheets for Aluminum Ramps

Enhanced Traction and Grip with Embossed Aluminum Sheets for Aluminum Ramps

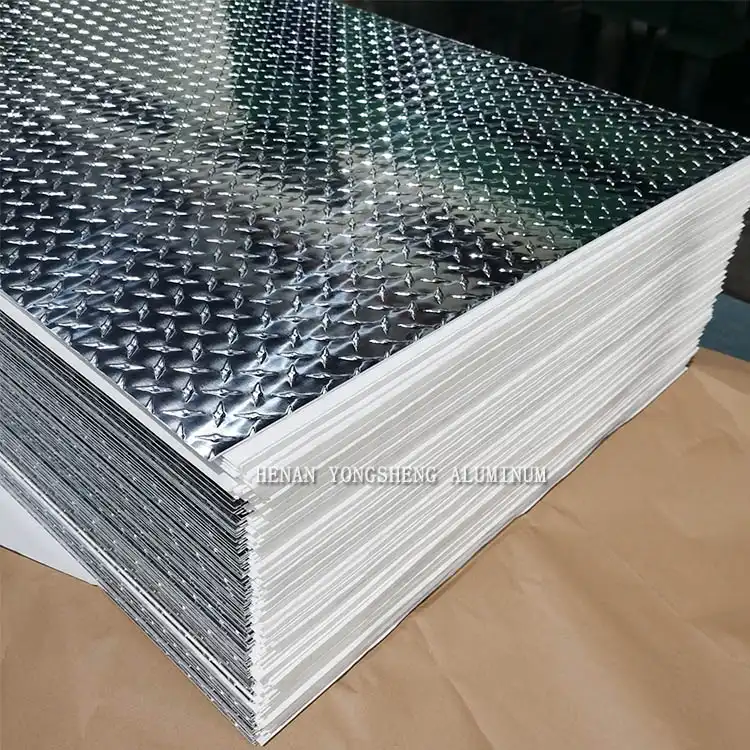

Embossed aluminum is designed with a textured surface that provides improved traction and grip compared to smooth surfaces. This enhanced traction offers several advantages in preventing slips and falls, making embossed aluminum sheets a popular choice for aluminum ramp construction.

1. Embossed Surface:

The embossed surface of the aluminum sheets features raised patterns or textures, creating a nonsmooth surface. Common patterns include diamond plate, checker plate, or other geometric designs. These patterns are achieved by pressing or rolling the aluminum sheets, resulting in raised ridges or indentations.

2. Improved Traction:

The embossed surface texture of aluminum sheets creates friction between the aluminum ramp and the objects or individuals traversing it. The raised patterns provide additional contact points and grip, reducing the chances of slipping or losing traction. The texture helps to disperse water, dirt, or other substances that could potentially create a slippery surface.

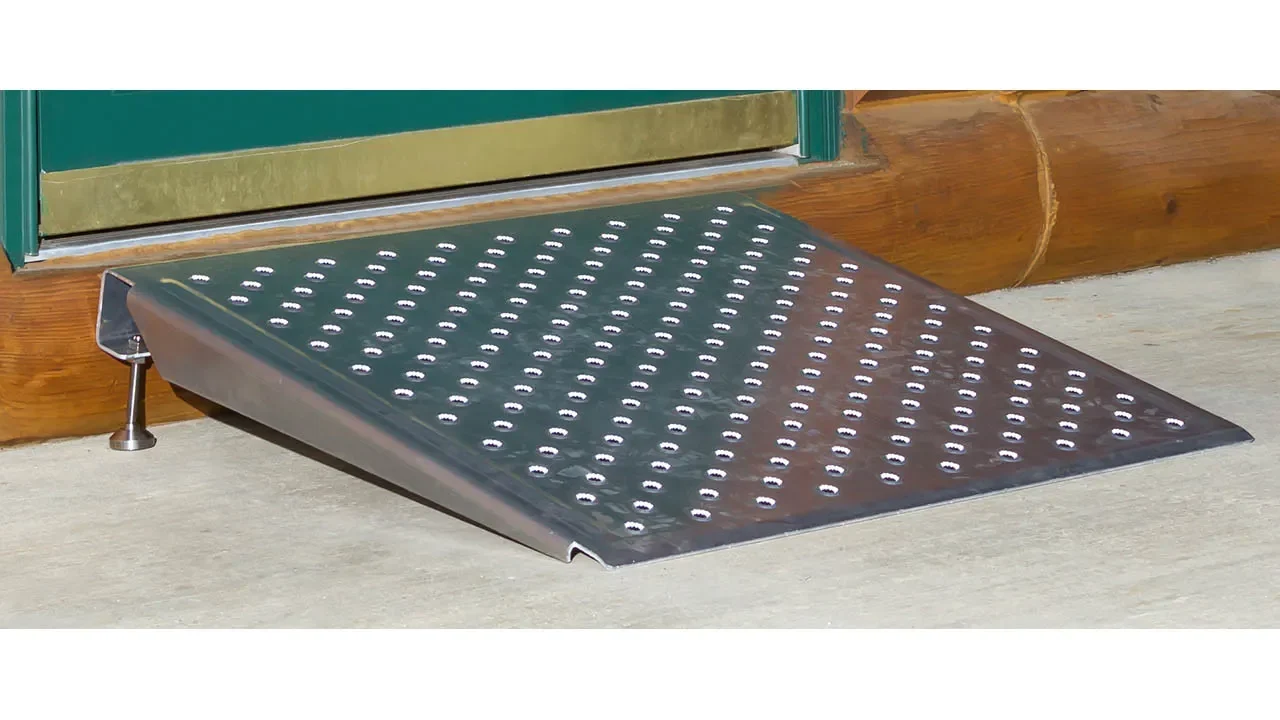

3. Prevention of Slips and Falls:

The primary advantage of embossed aluminum sheets is their ability to prevent slips and falls, particularly in wet, icy, or slippery conditions. The raised patterns increase traction, allowing individuals to maintain secure footing while ascending or descending the aluminum ramp. This feature is especially beneficial for aluminum ramps used in outdoor settings or in areas prone to moisture, such as loading docks or wheelchair access aluminum ramps.

Durable and Resilient

Embossed aluminum sheets offer exceptional durability and resilience, making them an excellent choice for aluminum ramps that are subjected to wear and tear, as well as heavy loads.

1.Increased durability and resistance to wear and tear

In addition to providing enhanced traction, embossed aluminum sheets offer the same durability and longevity as regular aluminum sheets. They are resistant to corrosion, rust, and degradation, ensuring a long lifespan for the aluminum ramp. The embossed pattern is not easily worn down, maintaining its traction properties over time.

2.Impact resistance

The embossed texture of the aluminum sheets contributes to their impact resistance properties. The raised patterns create a reinforced surface that can absorb and distribute impact forces, reducing the risk of damage or deformation. This impact resistance is particularly valuable in areas where the aluminum ramp may encounter heavy objects, equipment, or vehicles.

3. Ability to Withstand Heavy Loads:

Embossed aluminum sheets are designed to handle substantial weight and heavy loads. The raised patterns increase the load-bearing capacity of the sheets, distributing the weight more evenly across the surface. This ability to withstand heavy loads makes embossed aluminum sheets suitable for aluminum ramps used in applications such as loading docks or vehicle access.

4. Resistencia a la corrosión:

Like other aleaciones de aluminio, embossed aluminum sheets possess inherent corrosion resistance properties. They are highly resistant to rust, oxidation, and other forms of corrosion, even when exposed to moisture, chemicals, or harsh weather conditions. This corrosion resistance ensures the long-term durability and performance of the aluminum ramp, even in outdoor or high-moisture environments.

5. Longevity:

Due to their durability and resistance to wear, embossed aluminum sheets provide a longer lifespan compared to other ramp materials. They require minimal maintenance and are less susceptible to degradation or deterioration over time. The long-term durability of embossed aluminum sheets translates to cost savings and a reduced need for frequent repairs or replacements.

Embossed aluminum sheets’ increased durability and resilience make them an ideal choice for ramps that experience heavy usage and demanding conditions. Their resistance to wear and tear, impact resistance, ability to withstand heavy loads, and corrosion resistance contribute to the longevity and performance of the aluminum ramp. By selecting embossed aluminum sheets for aluminum ramp construction, you can ensure a durable and resilient structure that can effectively handle the demands of everyday use.

Easy Maintenance and Care

Embossed aluminum sheets not only offer enhanced traction and durability but also provide the advantage of easy maintenance and care. By following proper cleaning practices and ensuring the maintenance of the embossed surface texture, you can optimize the performance and lifespan of the aluminum sheets. Here are the details about easy maintenance and care for embossed aluminum sheets on aluminum ramps:

1. Regular Cleaning Practices:

Regularly clean the embossed aluminum sheets to remove dirt, debris, and other contaminants that may accumulate on the surface. Use a mild detergent or a non-abrasive cleaner mixed with water to gently scrub the surface. Avoid using harsh chemicals or abrasive cleaners, as they can damage the embossed texture and the protective finish of the sheets. Rinse the sheets thoroughly with clean water to remove any residue from the cleaning solution.

2. Soft Brush or Cloth:

Use a soft-bristle brush or a non-abrasive cloth to clean the embossed surface. Gently scrub the surface in a circular motion to remove stubborn dirt or stains. Avoid using rough brushes or abrasive materials that can scratch or dull the embossed pattern.

3. Mindful Cleaning Techniques:

Pay attention to the embossed patterns while cleaning to ensure that no debris or dirt is trapped within the texture. Use a brush or cloth with bristles that can reach into the crevices of the embossed pattern, ensuring a thorough cleaning. Take care not to apply excessive pressure that could potentially flatten or distort the embossed texture.

4. Protecting the Embossed Surface:

To maintain the embossed surface texture and optimize its performance, avoid dragging heavy objects or equipment across the aluminum ramp. Place protective mats or pads under heavy equipment or objects to prevent direct contact with the embossed aluminum sheets. Avoid using sharp tools or abrasive materials on the embossed surface, as they can scratch or damage the texture.

5. Inspecting for Damage:

Regularly inspect the embossed aluminum sheets for any signs of damage, such as dents, scratches, or corrosion. Promptly address any damage by repairing or replacing the affected sections to prevent further deterioration.

By following these maintenance practices, you can ensure that the embossed aluminum sheets on your aluminum ramps remain in optimal condition. Regular cleaning and gentle care will help remove dirt, preserve the embossed texture, and maintain the performance and appearance of the sheets. With proper maintenance and care, embossed aluminum sheets can provide long-lasting functionality and aesthetics for your aluminum ramps.

Yongsheng Embossed Aluminum

By incorporating embossed aluminum sheets into aluminum ramp construction, the risk of slips and falls is significantly reduced. The textured surface provides improved traction and grip, making it a reliable choice for ensuring the safety of individuals using the aluminum ramp. Whether it’s for residential, commercial, or industrial applications, embossed aluminum sheets offer enhanced traction and prevent accidents, making them an ideal option for aluminum ramps in various settings.

| Especificación | Chapa/bobina de aluminio gofrado |

| Aleación | Series 1000, 3000, 5000, 6000, 8000 |

| Temple | O-H112 |

| Espesor | 0.13 mm-6.5 mm (According to customer requirements) |

| Anchura | 3 mm-1600 mm (According to customer requirements) |

| Longitud | Según los requisitos del cliente |

| Aplicación | Construction, Flooring, Refrigerator, kitchen cabinet, etc. |

| Tratamiento de superficies | En relieve |

| Patterns | Classic, 1-5 barras, Checker, Altered, Diamond, Stucco, etc. |

| Normas | ASTM-B209, EN573-1, GB/T3880.1-2006, GB/T 24001-2016, GB/T 19001-2016 |

| Certificado | MTC, ISO9001, SGS, ROHS, DNV, TUV, ISO14001, ABS, CCS, CE. |

The specifications of the embossed aluminum we provide are as follows:

Aluminum Grade: 1000, 3000, 5000, 6000, 8000 Series

Form: Coil, Sheet, Plate

Temper: OH112, O / H14 / H32 / H24

Thickness: 0.13 mm6.5 mm

Patterns: Classic, 15 bars, Checker, Altered, Diamond, Stucco, etc.

Application: Pots, utensils, cooker, lamp, LED shell, traffic signs, etc.

Surface treatment: Mill finish, color coated sheets, anodized, mirror, embossed, checkered, etc.

Henan Yongsheng Aluminum Co., Ltd. is located in the industrial cluster of Gongyi City, Henan Province. Our factory focuses on the production and development of aluminum products such as aluminum sheet/coil, aluminum foil, aluminum strip, color-coated aluminum sheet/coil, aluminum circle, embossed aluminum, aluminum checker plate, mirror aluminum plate, anti-skid aluminum plate and so on.

La fábrica ocupa una superficie de 10.000 metros cuadrados y cuenta con 276 empleados. Todos nuestros productos se fabrican de forma independiente para ofrecerle un servicio excelente con entrega rápida, garantía de alta calidad, precios de fábrica y personal profesional de atención al cliente. Le invitamos a visitar la fábrica y esperamos establecer una buena relación comercial a largo plazo con usted.

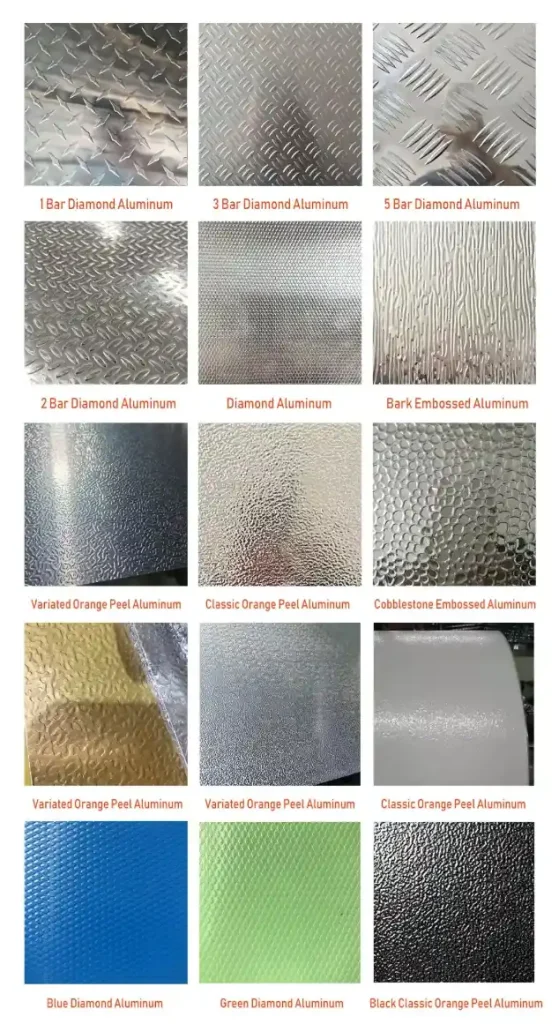

FAQ: Some Common Patterns of Embossed Aluminum

Embossed aluminum sheets are available in various patterns, each with its own unique aesthetic appeal and functional characteristics. Here are some common patterns of embossed aluminum:

1. Diamond Plate:

Diamond plate is one of the most recognizable patterns of embossed aluminum. It features a raised diamond-shaped pattern, with alternating peaks and valleys. Diamond plate provides excellent traction and is commonly used in applications where slip resistance is crucial, such as aluminum ramps, stairs, and industrial flooring.

2. Checker Plate:

Checker plate, also known as checkered or tread plate, consists of a repetitive pattern of raised squares or rectangles. This pattern creates a visually appealing look while providing enhanced grip and traction. Checker plate is often used in applications where slip resistance, durability, and aesthetics are important, including truck beds, trailer floors, and decorative elements.

3. Stucco Pattern:

Stucco pattern is characterized by a textured, pebbled surface that resembles the texture of stucco plaster. It has a non-directional pattern, with small raised dots or bumps evenly distributed across the aluminum surface. The stucco pattern offers a combination of aesthetics and improved traction, making it suitable for applications like wall cladding, decorative panels, and flooring.

4. 1-5 Bar Diamond Aluminum:

1-5 bar diamond aluminum refers to embossed aluminum sheets with a diamond-shaped pattern consisting of 1 to 5 raised bars. The diamond pattern provides excellent anti-slip properties and is commonly used in applications where slip resistance is crucial, such as aluminum ramps, stairs, and industrial flooring. The number of bars in the pattern can vary, with more bars typically offering enhanced grip and traction.

5. Bark Embossed Aluminum:

Bark embossed aluminum features a textured pattern that resembles the bark of a tree. It has a non-directional design with irregular raised ridges and grooves, creating a natural and rustic appearance. Bark embossed aluminum is often used in architectural applications, interior design, furniture, and decorative elements that require a distinctive and organic texture.

6. Variated Orange Peel Aluminum:

Variated orange peel aluminum refers to embossed aluminum sheets with an orange peel-like texture that varies in size and depth. The pattern consists of small, irregularly shaped raised bumps scattered across the surface, providing a unique and visually interesting appearance. Variated orange peel aluminum is popular in applications that require both aesthetics and improved slip resistance, such as vehicle flooring, decorative panels, and wall cladding.

7. Classic Orange Peel Aluminum:

Classic orange peel aluminum features a uniform and regular orange peel-like texture. The pattern consists of small, evenly spaced raised bumps, creating a visually appealing and textured surface. Classic orange peel aluminum is commonly used in various applications, including refrigerator panels, decorative elements, automotive interiors, and appliances.

8. Cobblestone Embossed Aluminum:

Cobblestone embossed aluminum has a pattern that resembles the texture of cobblestone pavement. It features a series of raised, rounded bumps arranged in a grid-like pattern across the surface, creating a visually interesting and textured appearance. Cobblestone embossed aluminum is often used in architectural applications, interior design, landscape accents, and decorative elements that require a unique and tactile surface. These embossed aluminum patterns offer different visual effects and functional characteristics, catering to various applications and design preferences. The choice of pattern depends on the specific requirements, aesthetics, and performance needs of the project.