Aluminum foil is an extremely thin aluminum material, generally referring to aluminum sheet products with a thickness of less than 0.2mm. The production process of aluminum foil mainly includes the following steps:

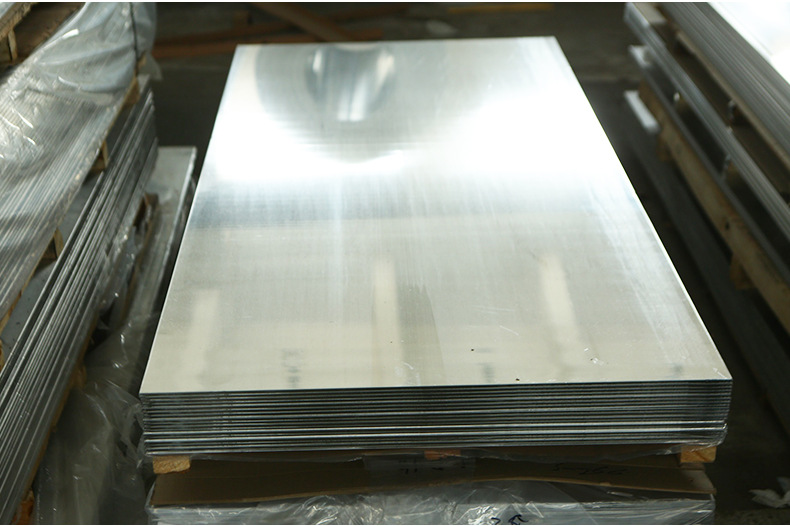

1. Aluminum sheet production: The production of aluminum foil first requires the production of aluminum sheets, usually using continuous casting and rolling processes or direct casting processes to produce aluminum sheets.

2. Rolling: Rolling aluminum sheets into thin aluminum sheets according to the required thickness. Usually, a multi roll rolling mill is used to gradually thin thick aluminum plates after multiple rounds of rolling, and ultimately produce aluminum foil.

3. Annealing: Aluminum foil may be subjected to excessive stress during the rolling process, resulting in excessive hardness. Therefore, it is necessary to anneal the aluminum foil to achieve the specified hardness and flexibility.

4. Surface treatment: The surface of aluminum foil is coated or painted to overcome the easy oxidation of the aluminum foil surface, reduce the oxidation rate of the aluminum foil, and increase its corrosion resistance.

5. Cutting: According to different needs, cut the aluminum foil according to the required width and length.

6. Packaging: After the production of aluminum foil is completed, it needs to be packaged to prevent moisture, pollution, and mechanical damage. Usually, transparent plastic bags, paper boxes, and wooden boxes are used for packaging.

In short, the aluminum foil production process requires multiple processes such as aluminum sheet production, rolling, annealing, surface treatment, slitting, and packaging. The manufacturing of aluminum foil requires very high precision and strict control. After years of technological accumulation and production experience, the quality, production efficiency, and output of aluminum foil have been greatly improved.