In the food industry, both aluminum foil and plastic containers are common choices, widely used for takeout, meal prep, and food packaging. However, many people notice that aluminum foil containers often come with a higher price tag. There are several underlying reasons for this price difference, involving material costs, performance characteristics, and environmental factors. Let’s dive into the details!

Material Costs of Aluminum Foil Containers

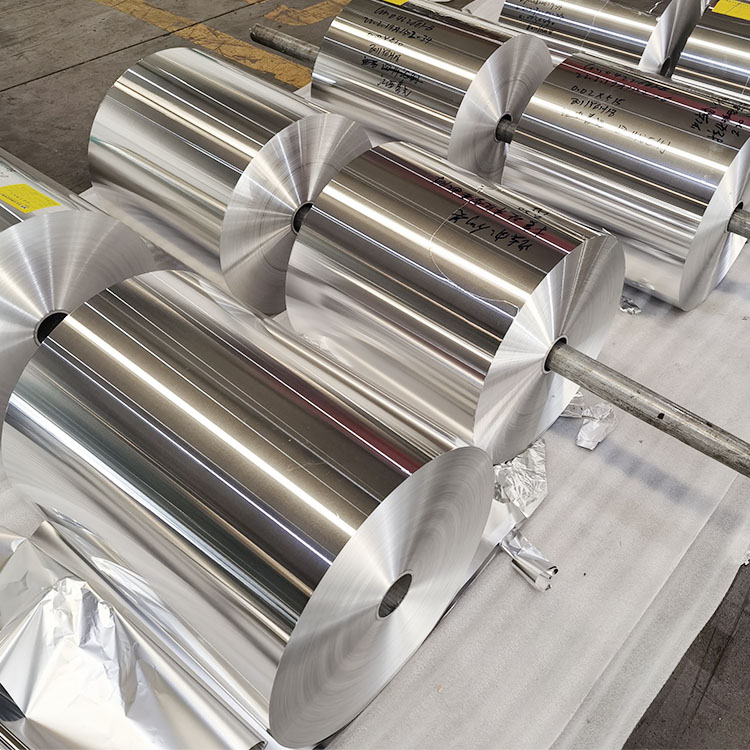

Firstly, the production process of aluminum foil is relatively complex. The raw material for aluminum is bauxite, and the process includes extraction, refining, casting, and rolling, all of which require substantial energy and resources. This complexity results in higher manufacturing costs. In contrast, the production process for plastic is simpler, with most raw materials sourced from petrochemicals, leading to less price fluctuation. Consequently, aluminum foil containers usually have a higher manufacturing cost, which directly impacts retail prices.

Heat Resistance and Safety

Aluminum foil containers significantly outperform plastic ones in terms of resistencia al calor. Aluminum can withstand high cooking and baking temperatures without deforming or releasing harmful substances. This means they can be used to heat various foods, including those that require high temperatures. Many plastic containers, on the other hand, may release harmful chemicals or warp under heat, compromising food safety. This heat-resistant property adds to the market value of aluminum foil containers, particularly in the context of high-end dining and takeout.

Protectiveness and Sealability

Aluminum foil trays offer excellent sealability, effectively preventing air and moisture from entering, thereby preserving food freshness. This feature is particularly vital for items that need to maintain quality, such as baked goods and seafood. In contrast, many plastic containers struggle with sealing, making them less effective at preventing oxidation or moisture loss. This difference in performance enhances consumer preference for aluminum foil containers, contributing to their higher price.

Recyclability and Environmental Impact

In today’s increasingly eco-conscious society, the recyclability of aluminum becomes a significant selling point. Aluminum is highly recyclable, with only 5% of the energy required to produce new aluminum from recycled material. This contrasts sharply with plastic, which often has a complicated recycling process and can contribute to long-term pollution. Thus, more consumers are willing to pay a premium for environmentally friendly aluminum foil containers.

Use Cases and Market Demand

Aluminum foil containers are typically used in high-end catering, takeout, and baking scenarios. These domains require strict standards for packaging quality, food safety, and overall food experience, leading consumers to invest more in a better product. On the other hand, plastic containers are often employed for everyday meals and general food packaging, resulting in fierce competition and lower prices. Therefore, the market positioning and demand for aluminum foil containers contribute to their rising costs.

Conclusión

In summary, while aluminum foil containers are generally more expensive than their plastic counterparts, their advantages in heat resistance, sealability, safety, and environmental impact justify this difference. When choosing a container, consumers care about more than just price; they consider food safety and environmental ramifications as well. So, aluminum foil containers, as a reliable food packaging option, are worth the investment!

As awareness of health and environmental issues continues to rise, the demand for aluminum foil containers may further increase, enhancing their market value. I hope this analysis helps everyone understand the advantages and value of aluminum foil containers better!