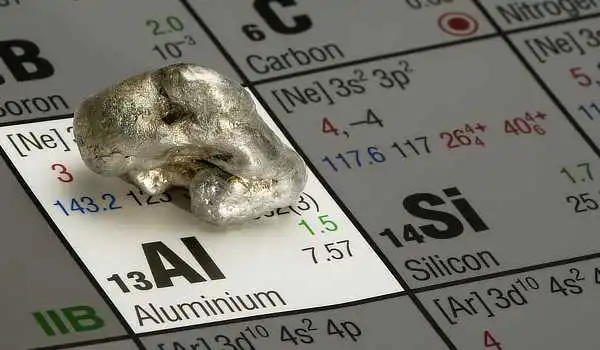

Fact 1: Discovery of Aluminum: The most abundant materials in the earth’s crust.

The element aluminum material accounts for about 8% of the total mass of the Earth’s crust. The American chemist Charles Martin Hall and the French chemist Paul-Louis-Thouëlle Eyrou discovered the Hall-Eyrou method in 1886, which was the first commercial method of producing aluminum.

Aluminum-containing ores have been used for dyeing and drug preparation as far back as antiquity. However, it wasn’t until the 18th century that the true nature and existence of aluminum became known to science.

In 1754, the Swedish chemist Axel Fredrik Cronstedt discovered an alloy of aluminum and mercury called “mercurial aluminum”. He extracted the new metal by heating the ore and reacting it with mercury. However, it was not recognized at the time that the element in this alloy was a separate metal.

In 1825, Danish physicist Hans Christian Ørsted took a further step by attempting to isolate pure aluminum from mercury-aluminum alloys. He isolated pure aluminum powder from it by reacting mercurial aluminum with an acid. However, this method was still unsuccessful in obtaining high purity aluminum.

A few years later, in 1827, the German chemist Friedrich Wöhler and the French chemist Charles Martin Hall independently discovered pure aluminum almost simultaneously. Wöhler used a method similar to Ørsted’s to isolate pure aluminum from it by reacting it with aluminum chloride. Hall, on the other hand, developed an electrolytic method to prepare pure aluminum by electrolyzing molten alumina.

Fact 2: Hall’s electrolysis method

Hall’s electrolysis method later became the primary method of producing aluminum material industrially. Hall’s electrolysis method laid the foundation for the mass production of aluminum material. In 1886, Hall, with a partner, founded an aluminum material production company and began commercial production of aluminum. This discovery led to a dramatic drop in the price of aluminum material, making it a widely used material.

The process of aluminum material discovery took the efforts and exploration of multiple scientists. From the discovery of the earliest mercury-aluminum alloys to the isolation of pure aluminum material and breakthroughs in industrial production, the process lasted for decades. Today, aluminum is an important engineering material used in a wide variety of fields, driving the development of modern industry and technology.

Fact 3: Aluminum Material is one of the most widely used metals in industrial production.

Aluminum material plays an important role in the aerospace industry. Aluminum’s outstanding lightweight and strength make it ideal for aircraft manufacturing. From fuselage shells to internal components, aircraft fuselages, wings, tails, wing girders and engine parts are often manufactured using aluminum material. Aluminum material are advantageous because they provide enough strength to cope with the forces and vibrations of flight, while reducing overall aircraft weight and improving fuel efficiency and performance. In addition, aluminum material’s corrosion resistance makes it an indispensable material in aircraft manufacturing. Aluminum alloys is used in medical devices, artificial limbs and wheelchairs. Aluminum products are biocompatible, lightweight and durable for a variety of medical and health applications.

Aluminum materials used in the automotive industry is to manufacture car bodies, engine parts and interior components. The use of aluminum materials reduces the weight of automobiles, improves fuel efficiency and reduces exhaust emissions. Through heat treatment and alloying, the strength and plasticity of aluminum materials can be improved to the point where its strength can reach approximately 570 MPa to 620 MPa, so aluminum materials is also widely used in the military and defense fields, where high-hardness aluminum materials are used to manufacture military equipment such as military aircraft, warships and armored vehicles.

Fact 4: How does the plane take off?

The usage of aluminum materials in transportation is also very common. Aluminum materials is used to make cars, trains, ships, and airplanes because of how lightweight metal is. Vehicles and aircraft are lighter because to the usage of aluminum, which also enhances their performance and fuel economy.

The 7000 series aluminum alloy is the most widely used aluminum alloy in the aerospace sector. Due to their outstanding corrosion resistance and high strength, 7000 series aluminum alloys are utilized extensively in aircraft applications. Particularly, two aluminum alloys—7075 and 6061—are widely used in aeronautical applications:

7075 Aluminum Alloy: 7075 alloy is a high-strength aluminum alloy composed primarily of aluminum, zinc, copper, magnesium and other alloying elements. It has outstanding strength and excellent corrosion resistance and is widely used in components such as aircraft structural members, aircraft casings, wing beams and connectors.

Aluminum Alloy 6061: Alloy 6061 is a general-purpose aluminum alloy composed of aluminum, magnesium and silicon. It has good strength and machinability and is widely used in the aerospace field for aircraft structures, spacecraft parts and space instruments.

These aluminum materials are perfect for the production of aircraft and spacecraft due to their high strength, low weight, and corrosion resistance, which have all been extensively studied and demonstrated in aerospace applications for a long time.

Aluminum materials is used extensively not just in the aircraft industry but also in the production of some unusual automobiles. For example, aluminum materials are frequently used for the skeletons of balloons and hot air balloons to give lightness, strength, and stability.

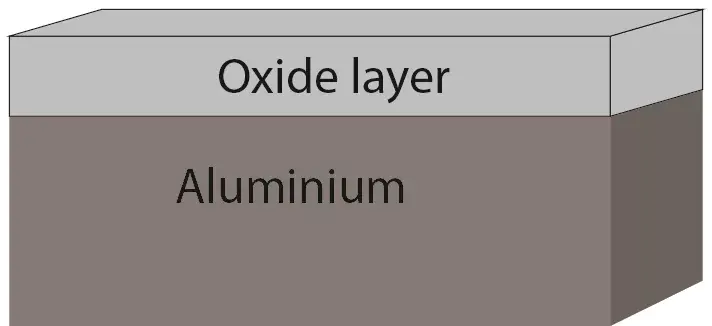

Fact 5: The most antioxidant metal

When aluminum reacts with oxygen in the air, an oxide layer quickly forms on the surface. This is due to the fresh metal on the surface of aluminum reacting with oxygen to form aluminum oxide. Aluminum oxide continues to form, grow, and gradually cover the entire aluminum surface in the presence of oxygen. This process is often referred to as oxidation or oxidative corrosion. This oxide layer consists mainly of aluminum oxide (Al2O3) and has a certain thickness and stability. This aluminum oxide film prevents further oxidation and corrosion, giving aluminum a long service life in harsh environments.

Corrosion resistance: The oxide layer protects the aluminum surface from further corrosion. The oxide layer is a dense barrier that prevents further exposure to oxygen, moisture and other corrosive substances.

Insulation: Oxide layer is an insulating material with good electrical insulation properties. This makes oxide layer important in electronic and electrical applications such as capacitors and electronic components.

Good Adhesion: The oxide layer has good adhesion to the aluminum substrate and is not prone to peeling or flaking. This helps maintain the integrity and stability of the oxide layer.

Good abrasion resistance: The oxide layer has a certain degree of hardness and abrasion resistance and is able to resist surface abrasion and scratches.

Fact 6: The best food packaging materials

Aluminum is very common in the packaging industry. Aluminum foil is used in food packaging, tobacco packaging and pharmaceutical packaging, among others. Feuille d'aluminium has excellent barrier properties that do not affect the taste of the food, as well as a good seal that protects the product from light, oxygen and moisture. Aluminum is widely used in the food and beverage industry. Aluminum cans are the most common example used to contain beverages and food products. This is because aluminum cans, foils and boxes keep food fresh.

Fact 7: The most recyclable metal material

Aluminum is an excellent recyclable material. Recycled aluminum cans can be smelted and remanufactured many times over without losing their properties or quality. And recycling 1 ton of aluminum uses only about 5% of the energy required for primary production. This makes aluminum an important part of sustainable development and environmental awareness.

Globally, recycling rates for aluminum cans are relatively high, often exceeding 50% or more in many developed countries. Some countries have even achieved recycling rates of over 90%. After being placed in the recycling bin, our usual used aluminum cans are first sorted and processed to separate them from other waste and prepare them for recycling. Then they are cleaned and compressed: aluminum cans are cleaned and compressed to take up less space during transportation and storage. Finally smelted and remanufactured: Smelted aluminum cans are converted into aluminum ingots, which can then be used to produce new aluminum products, such as new aluminum cans, automotive parts, and construction materials.

Recycling aluminum cans also reduces the load on landfills and extends the life of landfills. It helps to reduce the demand for limited aluminum resources, thus reducing the dependence on ore mining. Recycling aluminum cans is a crucial environmental practice that has a big impact on lowering resource use, saving energy, and preserving the environment. We can further raise the rate of aluminum can recycling and support sustainable development by combining the efforts of people and society.

Fact 8: Top 5 metals that best conduct electricity

Despite being one of the most often utilized conductive materials, aluminum also boasts strong electrical conductivity. Aluminum is frequently utilized in electrical and electronic equipment because its electrical conductivity is approximately 61% greater than copper’s. A lot of electricity transmission and distribution systems use aluminum conductors. When compared to copper conductors, aluminum conductors are less expensive and heavier, making them the material of choice for long-distance transmission lines.

This list shows the conductive order of some commonly used metals and alloys, based on equal sizes.

- Pure silver

- Pure copper

- Pure gold

- Aluminium

- Zinc

- Nickel

- Brass

- Bronze

- Le fer

- Platinum

To ensure effective and dependable power transmission, aluminum conductors’ conductivity and corrosion resistance are maximized. Information technology is another area where aluminum has many useful applications. Aluminum, for instance, is frequently used in the construction of computer heat sinks and housings for electronic equipment because of the metal’s excellent electrical conductivity and heat dissipation capabilities, which support the equipment’s stability and performance. In the production of electronics, aluminum is used in a wide variety of products, including heat sinks for electrical devices, computer housings, and cell phone housings. The stability and performance of electronic equipment are maintained thanks to aluminum’s excellent thermal and electrical conductivity qualities.

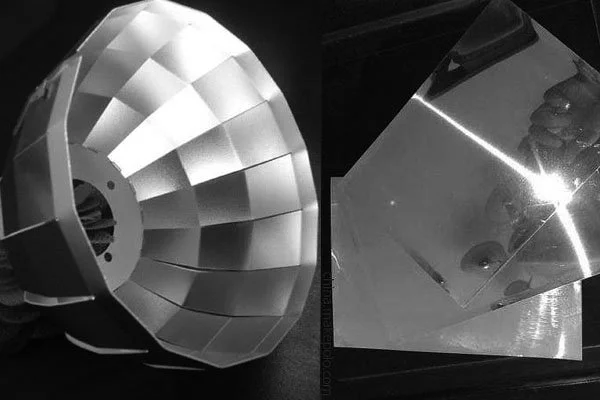

Fact 9 Aluminum Reflective Properties

Aluminum is widely used in the manufacture of reflectors, mirrors and optical devices due to its excellent reflective properties. Aluminum’s high reflectivity makes it useful in applications such as spotlights, solar reflectors and vehicle headlights. The solar industry often uses aluminum for solar panels and collectors. Aluminum has excellent light reflective properties and corrosion resistance, which improves the efficiency and longevity of solar equipment.

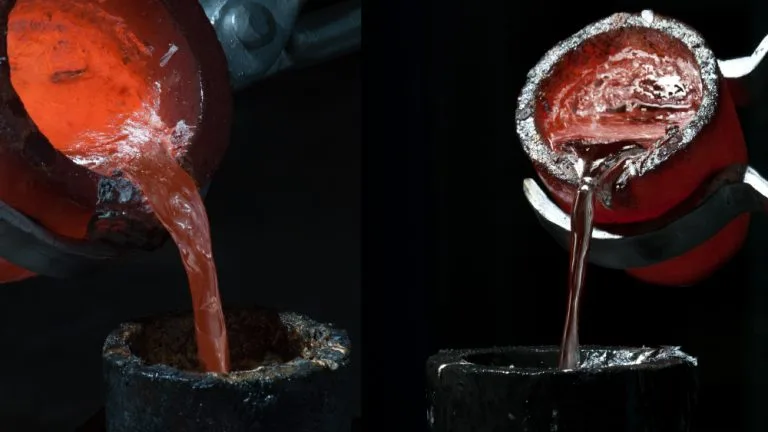

Fact 10 Aluminum Melting Point and Machinability

Because aluminum can suit the unique requirements of various applications, aluminum materials are utilized in a wide range of industries, including aircraft, automobile manufacture, and construction. Because of its low melting point of 660 degrees Celsius (1,220 degrees Fahrenheit), aluminum is simpler to melt and cast. Additionally, aluminum can be cold manipulated to increase its strength and plasticity (e.g., rolling, stretching, and forging).

Conclusion: Aluminum, as an important metallic material, has a wide range of applications and unique properties. Its lightness, electrical conductivity, corrosion resistance and recyclability make it one of the indispensable materials in modern industry. By gaining a deeper understanding of the properties and applications of aluminum, we can make better use of its advantages and promote the development of technology and society. At the same time, we should also focus on the sustainability and environmental impact of aluminum and take appropriate measures to promote recycling and environmentally friendly production of aluminum materials.

What is aluminum used for?

Aluminum is used in various industries and applications due to its advantageous properties. The most common uses of aluminum include: Transportation, construction, electrical, consumer goods.

- Transportation: Aluminum is extensively used in the automotive industry for manufacturing vehicle bodies, engine components, wheels, and other parts. Its lightweight nature helps improve fuel efficiency and reduce emissions. In the aerospace industry, aluminum is used in aircraft structures, wings, fuselages, and other components.

- Construction and Architecture: Aluminum is widely employed in the construction sector for windows, doors, roofing systems, curtain walls, and structural elements. It offers durability, corrosion resistance, and design flexibility while being lightweight.

- Electrical and Electronics: Aluminum is used in electrical wiring, power transmission lines, and conductors due to its excellent electrical conductivity. It is also utilized in electronic devices, heat sinks, and capacitors, benefiting from its thermal conductivity and lightweight properties.

- Consumer Goods: Aluminum is found in various consumer products, including appliances (such as refrigerators, ovens, and washing machines), kitchen utensils, packaging materials, furniture, and decorative items. Its corrosion resistance, aesthetic appeal, and ease of fabrication make it popular in these applications.

- Packaging: Aluminum foil and containers are widely used for packaging food, beverages, pharmaceuticals, and other products. Aluminum’s barrier properties, lightness, and ability to withstand high and low temperatures make it ideal for preserving and protecting perishable goods.

- Industrial Applications: Aluminum is utilized in diverse industrial sectors for machinery and equipment manufacturing. It is commonly used in the production of industrial machinery, storage tanks, pipes, and structural components due to its strength, corrosion resistance, and machinability.

- Renewable Energy: Aluminum is employed in renewable energy technologies such as solar power systems and wind turbines. Its lightweight nature makes it suitable for solar panels, while its strength and corrosion resistance are beneficial for wind turbine components.