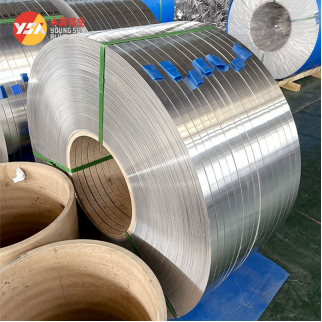

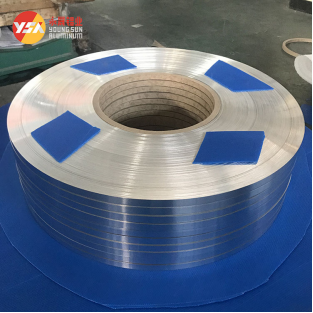

5083 aluminum is a high-strength, corrosion-resistant alloy that has become increasingly popular across various industries. Known for its excellent weldability, formability, and durability, the Bande d'aluminium 5083 is particularly valued in marine applications, construction, and transportation. In this article, we will explore the properties, benefits, and diverse applications of 5083 aluminum strip, highlighting why it is considered a reliable material choice.

What is 5083 Aluminum?

The 5083 alloy is part of the 5000 series of aluminum alloys, which are primarily alloyed with magnesium and a small amount of manganese. This combination enhances the material’s strength and resistance to corrosion, especially in harsh environments.

Key Properties

1. High Resistance to Corrosion:

– 5083 aluminum exhibits excellent resistance to corrosion, making it ideal for use in marine and industrial environments where exposure to moisture and chemicals is common.

2. Good Soudabilité:

– This alloy is known for its strong welds and can be easily joined using various welding methods, including MIG and TIG welding, without compromising its integrity.

3. Strength and Durability:

– 5083 aluminum has a high tensile strength, allowing it to withstand rigorous conditions while maintaining structural integrity.

4. Formability:

– The alloy can be easily formed into complex shapes, which is essential for many manufacturing processes.

5. Lightweight:

– Like other aluminum alloys, 5083 is lightweight, which is crucial for applications where reducing weight can enhance efficiency and performance.

Benefits of Using 5083 Aluminum Strip

1. Versatility:

– The versatility of 5083 aluminum allows it to be used in a wide range of applications, from marine constructions to transportation and beyond.

2. Sustainability:

– Aluminum is fully recyclable without losing its properties, making 5083 an environmentally friendly choice that supports sustainable practices.

3. Le rapport coût-efficacité :

– While the initial cost may be higher than some alternatives, the longevity and durability of 5083 aluminum often result in lower lifecycle costs, making it a wise investment.

4. Aesthetic Appeal:

– The availability of different surface finishes allows for attractive visual designs, enhancing the overall look of finished products.

Common Applications of 5083 Aluminum Strip

1. Marine Industry:

– One of the most significant applications of 5083 aluminum strip is in the construction of boats and ships. Its corrosion resistance and strength make it ideal for hulls, superstructures, and other components exposed to seawater.

– The alloy is also widely used in the manufacture of marine fittings, such as railings, ladders, and other hardware.

2. Transportation:

– In the transportation sector, 5083 aluminum is used for truck bodies, trailers, and container systems due to its lightweight and durability. Its strength helps in creating robust and efficient designs that contribute to fuel savings.

3. Storage Tanks:

– The chemical and oil industries often utilize 5083 aluminum strips to manufacture storage tanks and pressure vessels. Its resistance to corrosion and ability to withstand pressure make it a reliable choice for hazardous materials.

4. Architectural Applications:

– 5083 aluminum is also used in various architectural elements, including cladding, window frames, and roofing systems. Its aesthetic qualities and structural strength contribute to modern building designs.

5. Automotive Components:

– In the automotive industry, the alloy is used for manufacturing components that require light weight and high strength, such as chassis parts and structural members.

6. Recreational Vehicles:

– RV manufacturers often use 5083 aluminum for constructing lightweight, durable, and corrosion-resistant structures, including frames and exterior panels.

Conclusion

5083 aluminum strip is a highly versatile and robust material that serves a wide array of applications across maritime, transportation, industrial, and architectural sectors. Its unique properties, including corrosion resistance, weldability, and strength, make it an ideal choice for demanding environments. As industries continue to prioritize sustainability and efficiency, the use of 5083 aluminum strip is likely to grow, cementing its place as a critical material in modern manufacturing processes.