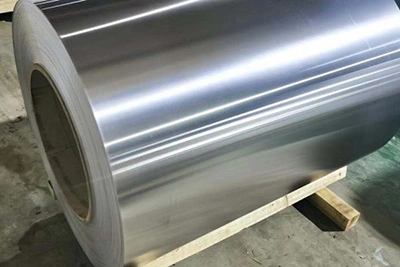

6061 Aluminum Coil Overview

6061 aluminum coil is the champion among aluminum alloy materials. Its availability extends to a range of pre-tempered and tempered grades such as annealed 6061-O, solution and artificially aged 6061-T6, and solution, stress relieved, tensile and artificially aged 6061-T651. Made from an aluminum magnesium silicon alloy, this alloy is known for its strength, corrosion resistance and weldability.

Yongsheng 6000 series aluminum alloys are widely used in automotive structural devices, 3C products, molds, precision processing products, shipbuilding, air conditioners, etc. This article will mainly introduce the characteristics, applications, advantages and disadvantages of 6061 aluminum coils, and help you learn more about Yongsheng 6061 aluminum coils.

6061 Aluminum Coil Characteristics

In terms of propriétés mécaniques, 6061 aluminum coils exhibit high tensile strength, typically in the range of 276-310 MPa (40,000-45,000 psi). Its yield strength is typically around 240 MPa (35,000 psi), and its elongation is usually in the range of 8-12%, allowing some deformation before failure.

The main chemical composition of 6061 aluminum coil includes 95.8% aluminum, and a small amount of magnesium (1.0-1.2%), silicon (0.4-0.8%) and copper (0.15-0.4%), which proves the corrosion resistance of 6061 aluminum coil , because the aluminum coil itself is flexible and ductile, it can also be easily shaped and formed into various structures. Compared to 5052, which is known for its marine-grade corrosion resistance, 6061 is stronger, more versatile, and more popular.

In terms of physical properties, the density of 6061 aluminum coil is about 2.7 g/cm3, which is relatively low compared with many other metals. It has a melting point of approximately 585 °C (1085 °F) and is easily processed by various manufacturing methods including casting, extrusion and rolling. In addition, 6061 aluminum coil also has thermal conductivity and electrical conductivity, which can dissipate heat efficiently.

6061 Aluminum Coil Applications

Aerospace industry:

6061 aluminum coils are widely used in the manufacture of aircraft structures such as aircraft wings, fuselage and landing gear components. Its high-strength weight can reduce the weight of the aircraft and ensure structural integrity.

Automobile industry:

In the automotive sector, 6061 aluminum coils are used to produce lightweight automotive components. These aluminum coils are used to make components such as engine parts, chassis frames and suspension systems. Other aluminum coil alloys such as 3003 aluminium coils are commonly used in the manufacture of automotive shells, body and door panels, and interior components.

Construction industry :

6000 aluminum coil is not as cheap as series 1 and series 3, so it is not commonly used in the construction industry. However, 6061 and 6063 aluminum are two counter-examples for the construction industry to make window frames and curtain walls. Common grades such as 1100 aluminium coils and 3003 aluminium coils are more suitable for building exterior wall materials, and Bobines d'aluminium 5052 are more suitable for coastal areas and areas with harsh environments. 3004 and 3105 have excellent corrosion resistance and weather resistance, which can effectively prevent the roof from being damaged by rain, ultraviolet rays and other natural factors. They also have good formability and can be customized according to the needs of the roof.

Electrical industry :

The electrical industry benefits from the electrical conductivity and corrosion resistance of 6061 aluminum coil. These coils are widely used in the production of power transmission lines, bus bars and electrical connectors. The excellent electrical conductivity of 6061 aluminum ensures efficient power transmission and minimizes energy loss.

Sports and leisure :

6061 aluminum coil is used in the sports and recreation industry for light equipment such as bicycle frames, golf club heads, baseball bats and camping gear. The strength and durability of 6061 aluminum contribute to the performance and longevity of these products.

Medical industry :

In the medical field, 6061 aluminum coils are used to develop various equipment and devices. These coils are used in the production of surgical instruments, prosthetics, wheelchairs and hospital furniture. The biocompatibility and corrosion resistance of 6061 aluminum make it more suitable for medical use than aluminum 5052.

Advantages Of 6061 Aluminum Coil

6061 aluminum coil offers several advantages in a variety of applications. First of all, it has excellent corrosion resistance, which is very suitable for outdoor and marine environments that are often exposed to moisture and harsh environments; moreover, 6061 aluminum coil has good formability and weldability, and is easy to manufacture and assemble processes; its high strength and weight ratio makes it suitable for lightweight construction without compromising durability; the alloy also has machinability properties that allow for efficient machining operations such as drilling, milling, and turning; even at high temperatures, the alloy maintains Dimensional stability ensures performance under thermal stress; 6061 aluminum coils can also be polished, coated, anodized, mirrored, embossed, latticed and other surface treatments to enhance the appearance.

Disadvantages Of 6061 Aluminum Coil

6061 aluminum coil has some disadvantages due to its inherent characteristics and practical considerations. First, it corrodes easily when exposed to certain environments, especially in the presence of acids. Although 6061 coil is relatively strong compared to other aluminum alloys, it may not be as strong as some steel alloys, limiting its suitability for applications requiring extreme durability. Cost-wise, 6061 aluminum coil can be more expensive than other aluminum alloys due to its specific composition and manufacturing process. Finally, its high thermal conductivity can create challenges for applications that require thermal insulation, resulting in energy loss and reduced efficiency.

Aluminum Coil Packaging

Yongsheng aluminum coil adopts the best packaging method – moisture-proof cotton plus moisture-proof paper plus plastic cloth plus stretch film thickened plastic skin packaging. The products will strictly abide by laws and regulations, and be packaged and labeled according to customer requirements. Strict care should be taken to avoid damage during storage or loading, and a clear label should be attached to the outside of the package to facilitate the identification of the product and quality information by both parties.

As a professional aluminum coil manufacturer and supplier, YSA can provide you with 6061 alloy aluminum coils for various applications. Our prices are reasonable and the quality is reliable. Commonly used spot goods can be delivered within 7 days at the earliest, and futures can be delivered within 15 days at the earliest. If you have special customization needs, you are welcome to contact us directly by email or phone.