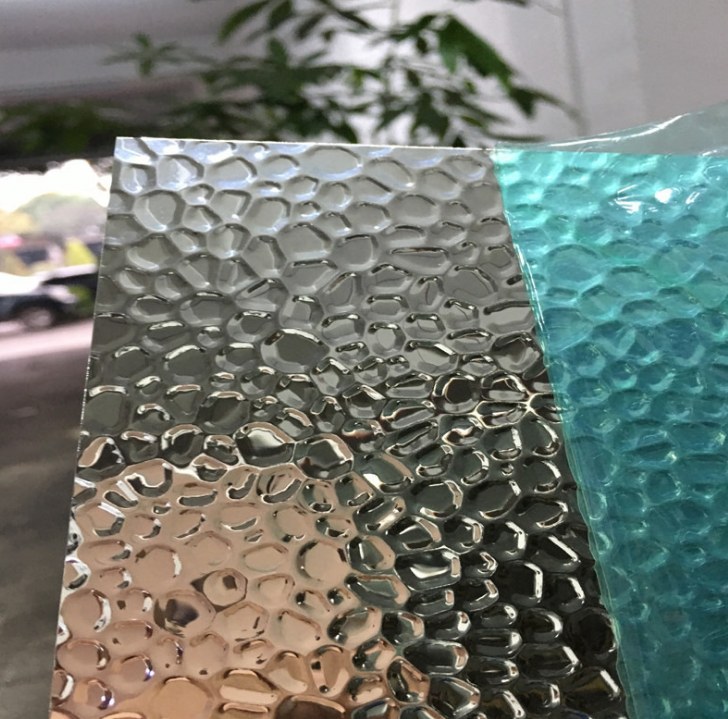

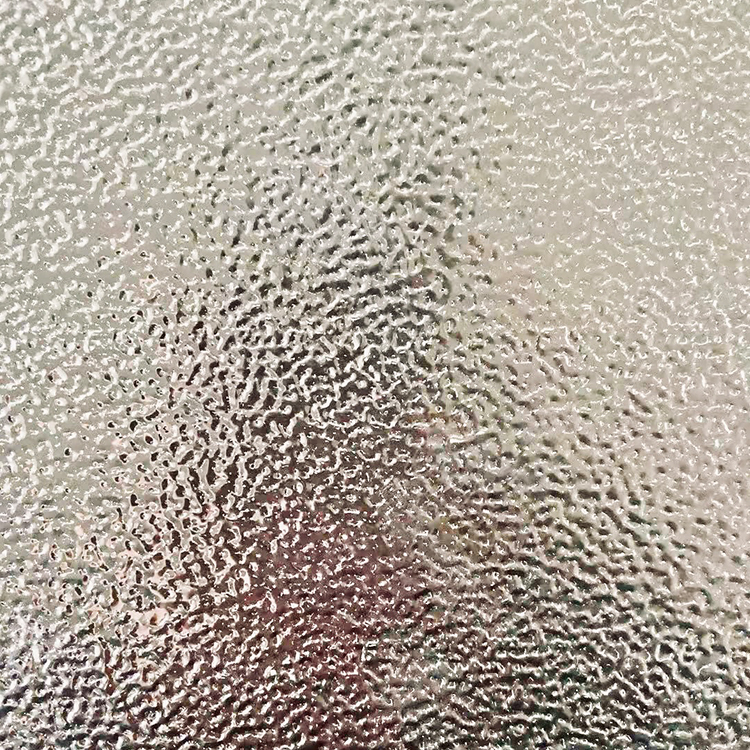

In the production process of embossed aluminum panels, the following problems may be encountered:

1. Poor embossing: Poor embossing may affect the aesthetics and quality of the aluminum plate. This problem is mainly caused by unreasonable mold design, and it is necessary to modify the mold at this time.

2. Uneven embossing depth: If the embossing depth is too deep or too shallow, it may lead to missing or too obvious details, affecting the aesthetic appearance of the aluminum plate. This issue may require adjustments to the mold and machine.

3. Scratches on the embossed surface: Scratches on the embossed surface may be caused by improper surface treatment of the board or accidents during the production process. This problem requires identifying the cause and making corresponding corrections.

4. Uneven embossing spacing: Uneven or regular embossing spacing can lead to regular repetition on the surface of aluminum plates, which can affect the overall aesthetics and market competitiveness of the product. Need to check if it is a mold issue.

5. Non compliant holes: The number and diameter of designed holes violate the final requirements, or are caused by improper mold adjustment or inaccurate hole positioning. This issue needs to be considered in the design and production process.

Overall, in the production process of embossed aluminum panels, it is necessary to carefully manage the design and manufacturing of molds, as well as multiple stages of the production process, in order to obtain high-quality embossed aluminum panel products.