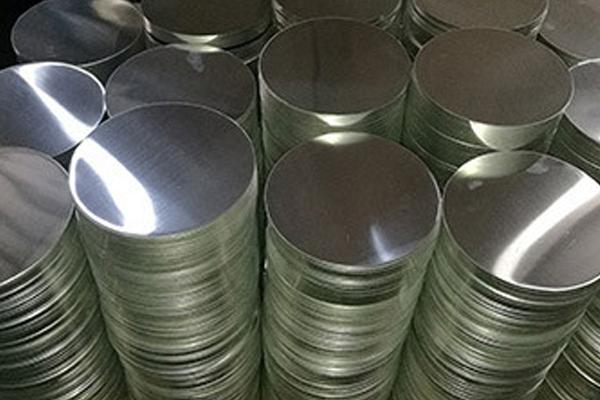

Aluminum wafers are widely used in electronics, daily chemicals, medicine, education, and automotive parts. Electrical appliances, insulation, mechanical manufacturing, automotive, aerospace, military, mold, construction, printing and other industries. One of the most widely used aluminum alloy plate and strip deep processing products is kitchen utensils such as non stick pots, pressure cookers, and hardware products such as lampshades and water heater casings.

Aluminum has good thermal and electrical conductivity properties. The thermal conductivity of high-purity aluminum with patterned aluminum plates, such as those completely annealed at 0-27 ℃, is 2.367W/(CM· K); The resistivity of ultrapure aluminum (99.990%) at 20 ℃ is 2.6548×10-8Ω·m, which is 64.94% IACS. The combination of aluminum’s excellent conductivity and low density makes it a good long-distance transmission conductor.

There are some aluminum components in laptops and many electronic devices, each playing an indispensable role. The heat dissipation component among them utilizes the good thermal conductivity and low density of aluminum.

Super strong corrosion resistance. The surface of aluminum discs and aluminum alloys has an aluminum oxide film that is incomparable thinner than cicada wings. This is a natural oxide film formed with oxygen in the air. The maximum thickness of this film formed at room temperature is 2.5-3.0nm25-30A. This layer of film is not only surprisingly thin, but also extremely dense and cannot penetrate oxygen. It is firmly bonded with aluminum discs, preventing them from being corroded or re oxidized. After the service life of aluminum discs and alloys has expired, more than 95% of regenerated aluminum can be obtained through treatment and remelting.

Integrating cleanliness, hygiene, aesthetics, and isolation. Aluminum discs and aluminum alloys are a silver white metal that, under normal atmospheric conditions, can always maintain a shiny, flawless white color, and are non-toxic and odorless. The cleanliness and hygiene of aluminum wafers make them an excellent packaging material for food, beverages, pharmaceuticals, and alcoholic beverages. They also have excellent printability and can print various patterns, colors, and patterns.

The strongest energy-saving and recyclability. Due to the strong corrosion resistance of aluminum discs and aluminum alloys, aluminum discs do not require maintenance under normal atmospheric conditions. Even after decades or even centuries of use, they remain intact and will not corrode, such as doors and windows, bridges, etc. After scrapping, recycling, and melting, more than 95% of recycled aluminum can be obtained, which is higher than any other engineering material. Even stainless steel is inferior, because stainless steel does not corrode during use, However, the burning loss of waste stainless steel during the smelting and regeneration process is much greater than that of aluminum.