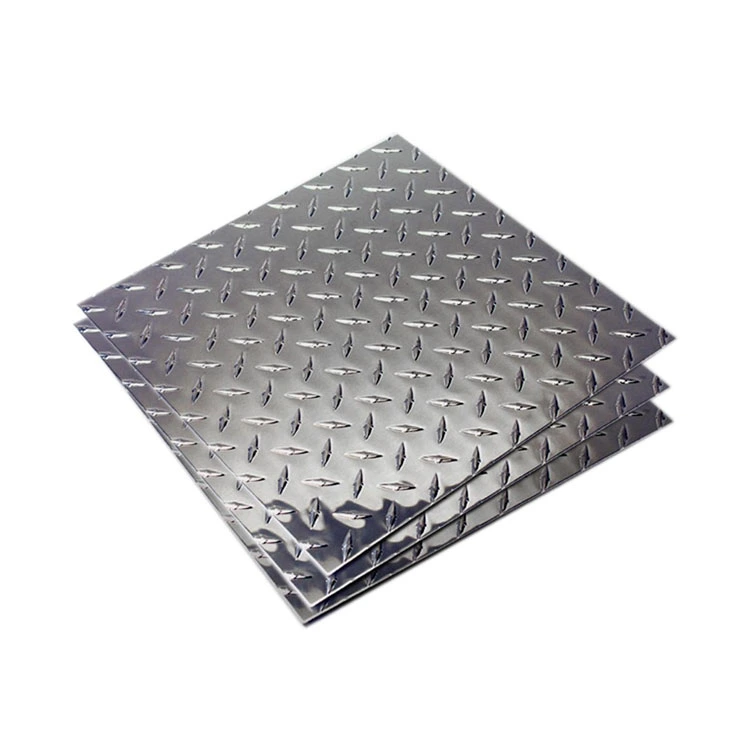

Aluminium diamond plate sheet, also known as tread plate or checker plate, is a popular material in many kinds of industries owing to its unique characteristics and multipurpose applications. This article will delve into the features, advantages, applications, selection criteria, installation tips, safety precautions, and cost analysis of aluminium diamond plate sheet.

Understanding Aluminium Diamond Plate Sheet

Aluminium diamond plate sheet consists of aluminum alloy and features a raised diamond pattern on its surface. The manufacturing process incl passing the sheet through rollers with diamond-shaped impressions, resulting in the distinctive pattern. This type of sheet is typically made from 3003 aluminium sheet ou Tôle d'aluminium 6061.

The characteristics of aluminium diamond plate sheet include excellent durability, high strength, lightweight composition, and exceptional corrosion resistance. These characteristics make it suitable for many kinds of demanding environments where durability and longevity are necessary.

Advantages of Aluminium Diamond Plate Sheet

One of the major advantages of aluminium diamond plate sheet is its durability and strength. It can withstand heavy loads, making it ideal for applications such as truck beds, trailer floors, ramps, and walkways. The diamond pattern offers extra structural integrity and rigidity.

The corrosion resistance of aluminium diamond plate sheet is another important advantage. It is highly resistant to rust and can stand exposure to moisture, chemicals, and hard weather conditions. Due to these characteristics, it’s suitable for outdoor applications or environments with corrosive elements.

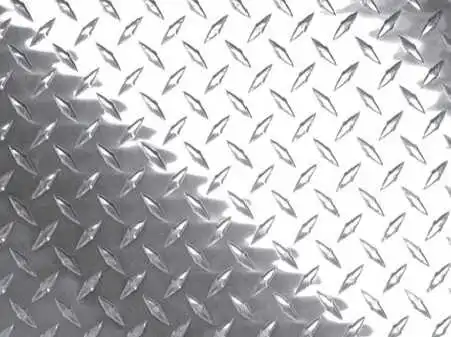

What’s more, the protuberant diamond pattern on the sheet offers fantastic slip resistance, making it a safe choice for areas where traction is important, such as staircases, flooring, and work platforms. The pattern strengthens grip and reduces the risk of accidents caused by slipping or sliding.

Furthermore, aluminium diamond plate sheet offers versatility and aesthetic feeling. It is available in many kinds of finishes, including mill finish, bright finish, and painted or coated options. This allows for customization and integration into different design styles, making it suitable for architectural and decorative purposes.

Common Applications of Aluminium Diamond Plate Sheet

Aluminium diamond plate sheet finds applications in a wide range of industries. In the transportation sector, it is commonly used for truck beds, trailer floors, and loading ramps due to its strength, durability, and slip-resistant properties. It ensures the safe and secure transportation of goods.

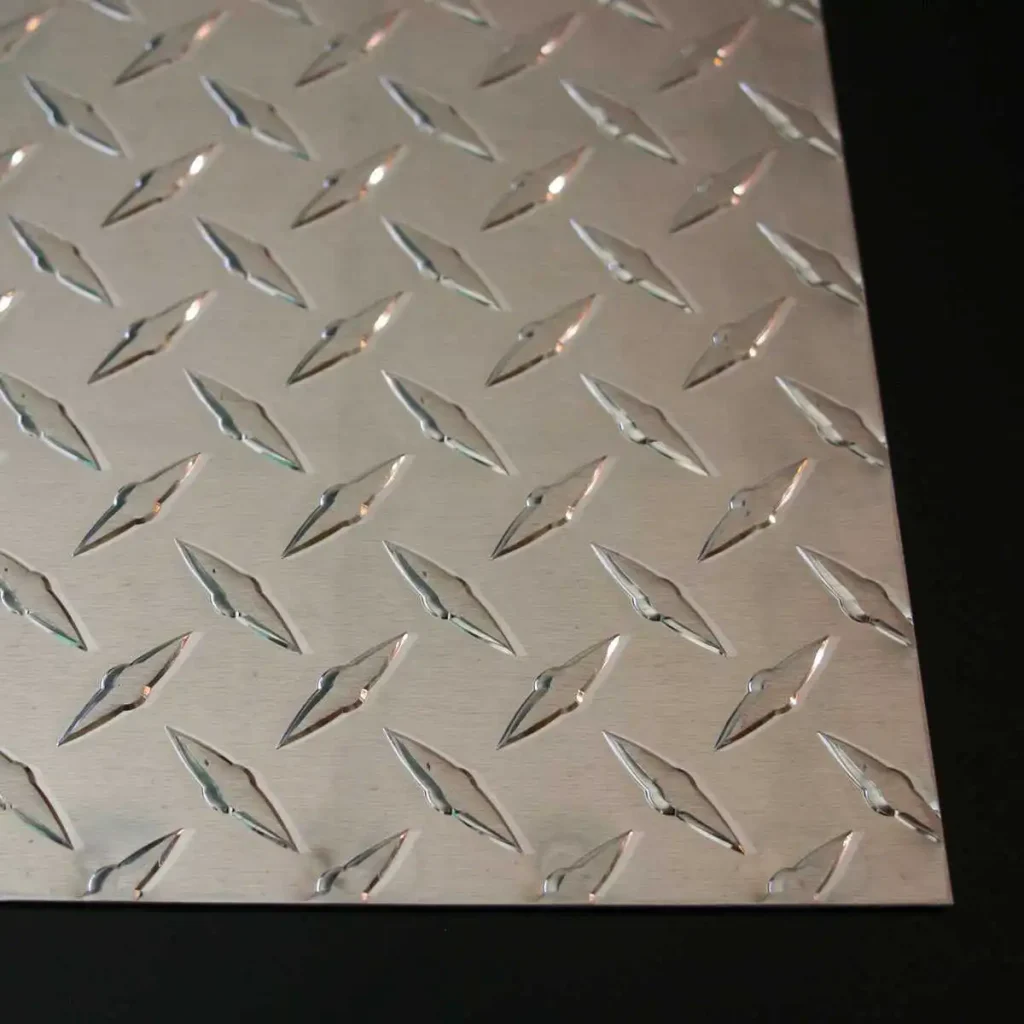

In the architectural and construction industry, aluminium diamond plate sheet is utilized for staircases, flooring, and wall coverings. Its aesthetically pleasing diamond pattern adds a unique touch to interior and exterior design elements. Additionally, it is used in industrial and commercial settings for toolboxes, storage units, workbenches, and platforms.

Furthermore, aluminium diamond plate sheet serves decorative and recreational purposes. It can be incorporated into interior design elements such as backsplashes, countertops, and furniture accents. Additionally, it is used for vehicle accessories like rocker panels, fender trim, and running boards, enhancing both style and functionality.

Choosing the Right Aluminium Diamond Plate Sheet

When selecting aluminium diamond plate sheet, several factors should be considered. These include thickness and size requirements based on the intended application, the choice of aluminum alloy 3003 or 6061 depending on the desired strength and corrosion resistance, and the surface finish options to match the aesthetic preferences.

It is also crucial to choose a reliable supplier who provides high-quality products. Consider factors such as reputation, customer reviews, and certifications. Quality sheets will ensure optimal performance and longevity.

The right aluminium diamond plate sheet you can choose is made by Henan Yongsheng Aluminum Co., Ltd. Henan Yongsheng Aluminum Co., Ltd. is located in the industrial cluster of Gongyi City, Henan Province. Yongsheng is an aluminum sheet/coil/foil/strip factory with 18 years of experience. The factory of Henan Yongsheng Aluminum Co., Ltd. focuses on the production and development of aluminum products such as aluminum sheet/coil, aluminum foil, aluminum strip, color-coated aluminum sheet/coil, aluminum circle, embossed aluminum, aluminum checker plate, mirror aluminum plate, anti-skid aluminum plate and so on. All products are independently produced to provide you with excellent service with fast delivery, high quality assurance, factory prices and professional customer service staff.

Installation and Maintenance Tips

Before installation, proper preparation is essential. Ensure the surface is clean, dry, and free from any debris that may affect the adhesion or integrity of the sheet. Cutting and shaping techniques will vary based on the thickness and size of the sheet. Tools such as saws, shears, or laser cutting methods can be used.

During installation, follow best practices and use appropriate fasteners or adhesives to secure the sheet in place. Properly sealing the edges and joints will enhance the sheet’s durability and prevent moisture penetration.

Maintenance of aluminium diamond plate sheet is relatively simple. Regular cleaning with mild soap and water is usually sufficient to maintain its appearance and remove any dirt or stains. Avoid using abrasive cleaners or harsh chemicals that may damage the surface.

Safety Precautions and Regulations

When handling and storing aluminium diamond plate sheets, it is crucial to follow safety guidelines. Wear appropriate personal protective equipment such as gloves and safety glasses to minimize the risk of injury. Store the sheets in a dry and well-ventilated area to prevent moisture buildup.

Compliance with industry standards and regulations is essential, especially in applications where safety is paramount. Ensure that the installation adheres to relevant codes and regulations to guarantee a secure and safe environment.

Cost and Value Analysis

The cost of aluminium diamond plate sheet can vary based on factors such as thickness, size, alloy type, surface finish, and supplier. While it may be initially more expensive than alternative materials, it offers long-term cost savings due to its durability, low maintenance requirements, and resistance to corrosion.

The value of aluminium diamond plate sheet lies in its versatility, longevity, and aesthetic appeal. It adds a touch of style to various applications while providing a robust and reliable solution. There turn on investment can be significant, considering its extended lifespan and reduced need for replacements or repairs.

Aluminium diamond plate sheet is a highly versatile material with numerous advantages and applications. Its durability, strength, corrosion resistance, slip resistance, and aesthetic appeal make it a popular choice in industries such as transportation, architecture, construction, and decoration. By understanding the characteristics, selecting the right sheet, following proper installation and maintenance guidelines, and prioritizing safety, one can fully harness the benefits of aluminium diamond plate sheet. Its long-term cost savings and value further solidify its position as a reliable and worthwhile investment in various projects.

FAQ

What’s the aluminum diamond plate sheets 4×8?

4×8 diamond aluminum plates are aluminum panels with a diamond pattern embossed on them, generally 4 feet (48 inches) wide and 8 feet (96 inches) long.

What is the thinnest diamond plate steel?

Steel Floor Plate also called Steel Diamond Plate or Steel Tread Plate is a hot rolled carbon steel plate rolled with a raised lug pattern that offers 4-way skid resistance. The thickness of the plate is measured at its thinnest point (lugs not included).