Woven fabric laminated reflective foil consists of woven textiles and aluminum foil, or an aluminized layer covered on the surface of a plastic woven film. Woven fabric aluminum foil insulation materials are widely used in building insulation. The structure is a composite of aluminized film and PE, woven fabric, and can also be composited with aluminum foil, bubbles, foam and other materials as insulation materials. It is widely used in building roof insulation. The material is easy to cut, has high tensile strength and durability.

How To Insulate Woven Fabric Laminated Reflective Aluminium Foil

First, reduce the heat exchange between indoors and outdoors by applying woven laminated aluminum foil on windows. Woven laminated aluminum foil can reflect solar radiation, reduce indoor heat loss, and improve the thermal insulation performance of windows. In winter, we can stick woven laminated aluminum foil directly on the window to prevent the exchange of cold air and hot air, making the indoor space warmer and more comfortable.

Secondly, woven laminated aluminum foil can be laid on the roof or wall to improve the thermal insulation performance of the building. Woven laminated aluminum foil can reflect most of the solar radiation, reduce the heat absorbed by the surface of the building, reduce the indoor room temperature, and then reduce the energy consumption of heating and improve the indoor thermal insulation effect. In winter, we can lay aluminized woven membrane on the roof and wall to reduce the heat exchange between indoors and outdoors and make the indoors warmer.

In addition, the warming effect can be improved by using woven laminated aluminum foil for thermal insulation clothing or bedding. Aluminized woven membrane has good thermal insulation performance, which can effectively prevent heat loss and improve the warming effect of clothing or bedding. In winter, we can choose some warm clothing or bedding with woven laminated aluminum foil to keep the body warm.

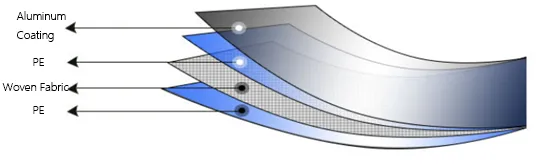

Woven Fabric Laminated Reflective Aluminium Foil Structure

Woven cloth laminated aluminum foil insulation materials are often used for composite or coated EPE, XPE, foam, kraft paper, glass fiber, asbestos, etc. The product is non-toxic, non-allergenic, recyclable, and environmentally friendly. It can reflect 95% of radiant heat.

| Nom | Woven Fabric Laminated Reflective Aluminium Foil Insulation Material | |||

| Structure | Aluminized film + PE + woven fabric + PE | |||

| Surface | Argent | Poids | 110gsm-220gsm | |

| Permeability | 0.015gsm/KPA | Couleur | Silver, Green, Blue, Etc | |

| Width(M) | 1-2.6M or customized | Tensile Strength (MD) | 200N/25mm | |

| Length(Per Roll) | 200m or customized | Tensile Strength (TD) | 250N / 25mm | |

| Reflectivity | >95% | Bursting Strength | 650N | |

Aluminum Foil Laminated Woven Fabric Features

- Aluminum foil woven fabric is environmentally friendly. It does not contain any dangerous chemicals or harmful substances that cause itching or respiratory problems. In addition, it does not release formaldehyde or volatile organic compounds, ensuring a healthy indoor environment.

- Compared with other types of aluminum foil insulation materials, this product has higher tensile strength and higher tear resistance.

- It is wear-resistant, anti-aging, lightweight, flexible, and easy to handle.

- It is an excellent low-cost waterproof building material.

- The product is in the form of woven cloth, which can be easily sewn together and conveniently installed on large-span buildings.

- Withstands continuous temperatures of 300ºC and peak temperatures of 550ºC.

- Aluminum face provides insulation from radiant heat sources.

- Completely impermeable to water, oil, acid, and smoke.

- Fabric is soft and easy to handle; it does not fray when cut with scissors.

- Completely opaque, suitable for protecting sensitive components.

- Soft fabric that resists cycles of movement.

- Its flame-retardant properties are permanent and do not degrade with use or expire.

How To Choose Woven Fabric Laminated Reflective Aluminium Foil

Choosing the right aluminum foil woven membrane is very important for protecting buildings. Aluminum foil woven fabric has certain functions such as heat insulation, thermal insulation, and moisture resistance. However, there are various brands and qualities of aluminum foil woven membranes on the market, and how to choose them correctly becomes the key.

Determine your needs and use environment

Before purchasing aluminum foil woven membrane, you must first clarify your needs and use environment. Different uses and environments require aluminum foil-woven membranes of different materials and specifications. For example, interior wall insulation, roof moisture resistance, floor insulation, etc. all require different products.

Material and quality

The quality of aluminum foil woven membrane depends on the material. A high-quality aluminum foil woven fabric is made of high-quality aluminum foil, polyethylene, and other materials and has good heat insulation, thermal insulation, and moisture resistance. When purchasing, carefully check the quality of aluminum foil and woven materials.

Breathability and moisture resistance

When choosing aluminum foil woven fabric, breathability and moisture resistance are very important factors. Aluminum foil laminated woven fabric with good breathability can effectively reduce the accumulation of water vapor inside the building and prevent mold. At the same time, aluminum foil woven fabric with good moisture resistance can effectively prevent the penetration of air and water vapor and keep the internal environment of the building dry.

Consider construction

When choosing aluminum foil laminated woven fabric, consider its construction convenience. Generally speaking, aluminum foil woven membrane should have good tear resistance and easy installation to ensure smooth construction.

Brand and after-sales service

When purchasing aluminum foil woven fabric, pay attention to choosing a brand with a reputation and good after-sales service. The guarantee of the brand can ensure the quality of the product and the quality of after-sales service, so that consumers can buy more assuredly.

Woven Fabric Laminated Reflective Aluminium Foil Price

First, the price of woven fabric laminated with aluminum foil is affected by the cost of raw materials. The raw materials of aluminized woven film are mainly high-density polyethylene (HDPE) and aluminized film. Generally speaking, the cost of raw materials accounts for a considerable proportion of the price of aluminum woven film, so the fluctuation of raw material prices will directly affect the price of aluminized woven film.

Secondly, the price of woven fabric laminated with aluminum foil is also affected by the manufacturing process and technical level. The manufacture of aluminized woven film requires a series of process flows, including extrusion, coating, weaving, and other steps, among which the link of coating aluminized film has an important influence on the quality and performance of the product. Therefore, the process level and technical content of manufacturing aluminized woven film are also important factors affecting the price of the product.

In addition, the price of woven fabric laminated aluminum foil is also affected by the quality of the product. The quality of aluminumized woven fabrics produced by different manufacturers also varies greatly. High-quality products are often more expensive because their quality and performance are more stable and reliable, while inferior products are cheaper but have a short service life and poor performance, so the price will also be low.