When it comes to purchasing aluminum sheets, it can be tempting to opt for the cheapest option available to save costs. However, selecting aluminum sheets based solely on price can lead to several significant issues that can affect the quality, performance, and longevity of your project. Here are the key reasons why you should avoid choosing cheap aluminum sheets.

Quality Concerns

Material Quality: Cheap aluminum sheets are often made from lower-grade aluminum or recycled materials that do not meet industry standards. This can result in sheets that are prone to defects such as cracks, inclusions, and inconsistent thickness.

Manufacturing Process: Manufacturers of low-cost aluminum sheets might cut corners during the production process. This can lead to inadequate heat treatment, poor surface finishing, and overall lower mechanical properties of the aluminum sheets.

Durability and Performance

Mechanical Strength: High-quality aluminum sheets are known for their strength and durability. Cheap alternatives may not have the same level of mechanical strength, making them more susceptible to bending, warping, or breaking under stress.

Corrosion Resistance: Aluminum is prized for its natural corrosion resistance. However, cheap aluminum sheets might not have the same level of protection due to impurities or insufficient alloying elements. This can lead to faster corrosion, especially in harsh environments, reducing the lifespan of the product.

Aesthetics and Finish

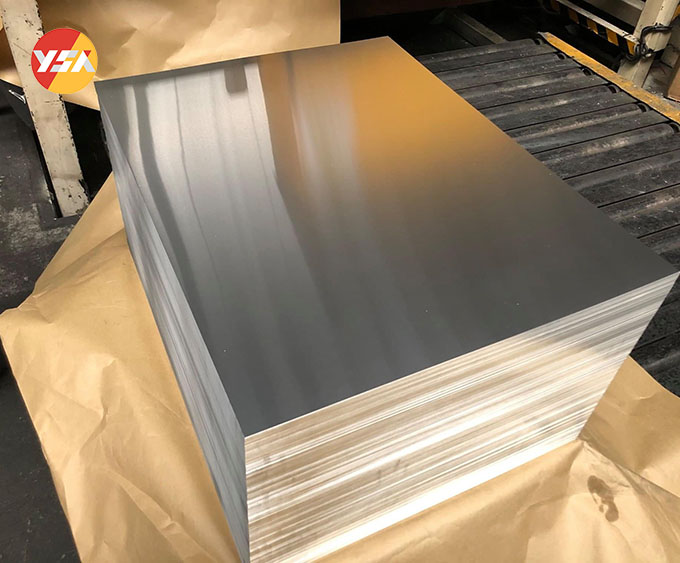

Surface Appearance: The appearance of aluminum sheets can vary significantly based on the quality of the raw material and the manufacturing process. High-quality sheets will have a smooth, consistent finish, while cheaper options may have visible imperfections, discolorations, or an uneven surface.

Anodizing and Coating Compatibility: If your project requires anodizing or coating the aluminum sheets, low-quality materials may not respond well to these treatments, resulting in poor adhesion, uneven coloring, or peeling.

Compatibility with Other Materials

Alloy Composition: Aluminum sheets are often combined with other materials in various applications. The alloy composition of cheap aluminum sheets might not be compatible with other materials, leading to issues such as galvanic corrosion or weak joints.

Welding and Fabrication: Poor-quality aluminum sheets can present challenges during welding or fabrication. They might have inconsistent alloying elements, leading to weak welds, increased porosity, and other fabrication defects.

Long-Term Costs

Maintenance and Repairs: While the initial cost of cheap aluminum sheets may be lower, they often require more frequent maintenance and repairs due to their inferior quality and performance. This can lead to higher long-term costs and downtime for your projects.

Replacement Costs: Poor-quality aluminum sheets may fail prematurely, necessitating early replacement. This not only adds to your material costs but also incurs labor costs for removal and installation.

Conclusion

Choosing aluminum sheets based solely on price can result in numerous problems, including compromised quality, reduced durability, and increased long-term costs. To ensure the success of your project and the longevity of your materials, it is essential to prioritize quality and reliability over cost savings. Investing in high-quality aluminum sheets from reputable suppliers will provide better performance, aesthetic appeal, and overall value, ultimately saving you time, money, and headaches in the long run.