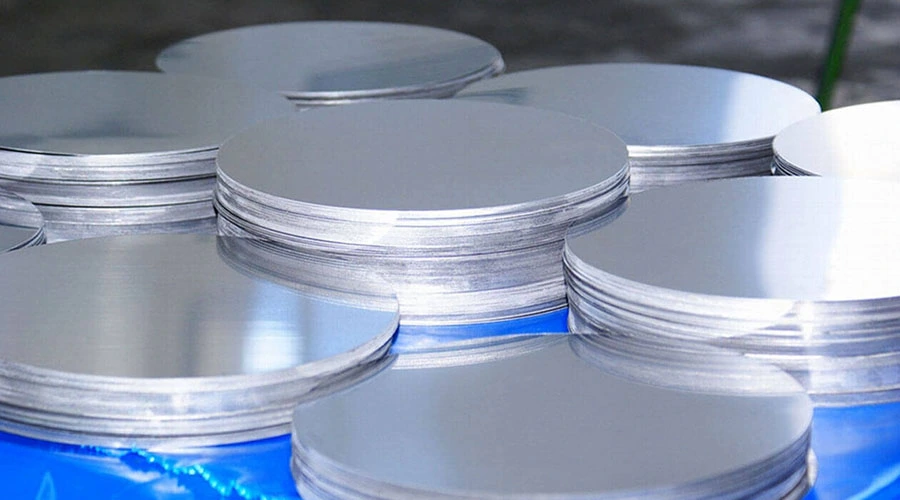

Yongsheng Pressure Cookers Aluminum Discs

Aluminum discs are widely used deep-drawn aluminum products and are also commonly used raw materials for manufacturing pressure cookers. Popular alloy grades include 3003, 3004, 5052 aluminum circles, etc. Yongsheng is a manufacturer of high-quality aluminum circles discs. Aluminum circles are widely used in the manufacturing of cookware, traffic signs, lamp housings, reflectors and other industries. Due to their excellent quality, they are also used in high-end kitchenware, such as pressure cookers. This article will focus on introducing to you the manufacturing process of Alluminio Yongsheng aluminum circles discs in the field of pressure cookers, the commonly used grades of aluminum circles for pressure cookers, the advantages of aluminum discs made into pressure cookers, and common questions.

Pressure Cookers Aluminum Circles Production Line

- Material selection: Choose high-quality aluminum circles as raw materials, which usually require high purity, no impurities, and smooth surfaces.

- Cutting: Cut the aluminum circle disc according to the size requirements of the pressure cooker, usually using cutting machine.

- Stamping: Stamp the cut aluminum circles discs into various parts of the pressure cooker, such as lid, bottom, body, etc.

- Forming: The stamped aluminum circles discs are formed, usually using a hydraulic press or a mechanical forming machine.

- Welding: Welding the formed parts, usually using technologies such as argon arc welding or laser welding.

- Surface treatment: Surface treatment is performed on the welded pressure cooker, such as polishing, spraying, etc., to improve appearance quality and corrosion resistance. High-end cookware generally adopts post-processing methods such as anodizing, enamel, spraying, and deep drawing according to customer needs. Ensure that the finished product has high grain grade and good surface finish.

- Testing: Conduct various tests on the finished pressure cooker, such as pressure test, leakage test, etc., to ensure that its quality meets standard requirements.

Commonly Pressure Cookers Aluminum Circles Series

Yongsheng’s pressure cooker production customers generally order 3000 series aluminum circles and 5000 series aluminum circles:

3000 series aluminum contains a certain proportion of manganese, which can improve the corrosion resistance of aluminum, making it less prone to corrosion in high-temperature and high-pressure environments and extending the service life of the pressure cooker. High pressure cookers of various shapes can also be manufactured through stamping, forming and other processing techniques to meet different needs. Compared with other metal materials, the cost of 3000 series aluminum circles is lower, which can effectively reduce the manufacturing cost of pressure cookers. For example, Midea Group, a well-known pressure cooker manufacturer in China, uses 3003 aluminum circles as the main raw material of pressure cookers. Its pressure cooker products have advantages such as wear resistance and high temperature resistance, and are widely welcomed by consumers.

As another commonly used raw material for pressure cookers, 5000 series aluminum circles contain a certain proportion of magnesium, which can improve the strength and toughness of aluminum and make it less likely to deform or break during use of the pressure cooker.

The chromium, manganese and other elements contained in the 5xxx series aluminum alloy can improve the corrosion resistance of aluminum and extend the service life of the pressure cooker. Chinese pressure cooker manufacturer Supor uses 5052 aluminum circles, 5182 aluminum circles as the main raw material of pressure cookers. Its pressure cooker products have the advantages of high strength, corrosion resistance, and high temperature resistance.

Advantages of Pressure Cookers Aluminum Circles

- Aluminum circles alloy pressure cookers are lighter than stainless steel pressure cookers because the density of aluminum alloy is lower than that of stainless steel. This makes the aluminum alloy pressure cooker easier to carry and operate, especially for the elderly or those with weak physical strength.

- The thermal conductivity of aluminum alloy discs pressure cookers is more than ten times that of stainless steel pressure cookers. The acquisition cost of aluminum alloy materials is low, and the price is also cheaper than stainless steel pressure cookers.

- Aluminum circles discs pressure cookers can hold non-acid, non-alkaline, and non-salty foods (but not recommended), such as rice, for a long time.

Features Of Yongsheng Pressure Cooker Aluminum Circles

- The material density is low and the finished product is light in weight.

- Excellent form ability.

- High reflectivity.

- The surface can be coated and will never fade.

- High elongation, can be used for deep drawing processing.

- High tensile strength and elongation, good fatigue strength.

- High grain grade and smooth surface.

- High surface quality and stable performance.

FAQ:

How To Bend Aluminum Sheet Into Circle?

Roll bending: Passing an aluminum sheet plate through a set of rollers gradually bends it into a round shape. This is usually done using a machine such as a roll bender or a three roll bender.

Brake Bending: Clamp an aluminum plate into a bending brake and use a lever to bend it into a circle. Suitable for thin aluminum sheets and small size aluminum circles.

Hammering: Using a hammer and a die to gradually shape the aluminum sheet into a round shape. Also suitable for thin aluminum plates sheets and small size aluminum circles.

Are Pressure Cookers Dangerous?

There are certain dangers in the use of pressure cookers. Mainly because the pressure inside the pressure cooker is very high, and if it is used improperly or malfunctions, it may cause personal injury and property damage. For example, accidentally touching a pressure cooker or being accidentally splashed by hot air and hot water when opening the pressure cooker may cause burns.

Can Pressure Cookers Explode?

The pressure cooker will not explode under normal use. However, there are certain risks associated with pressure cookers if they are not used correctly or proactively maintained.

Pressure cookers are designed to create a high-pressure environment inside the pot to increase cooking efficiency and food ripening speed. However, if the pressure cooker’s capabilities are exceeded, such as by opening the lid without properly releasing the pressure, or using a broken or inappropriate seal, the pressure within the pressure cooker may be released rapidly, causing an explosion. When using a pressure cooker, correct operating procedures must be followed. If you do not operate the pressure cooker correctly according to the instructions for use, such as forcibly opening the lid under high pressure, or overfilling with ingredients, the pressure in the pot may not be released normally, thereby increasing the risk of explosion.