History

1911 was an important time node in the history of food packaging in the world. Because this year is the first year of foglio di alluminio in the field of food packaging, and thus started its brilliant journey in the field of food packaging. As a pioneer of aluminum foil packaging ——, a Swiss chocolate enterprise, after more than 100 years of growth, has now become a household name brand (Toblerone).

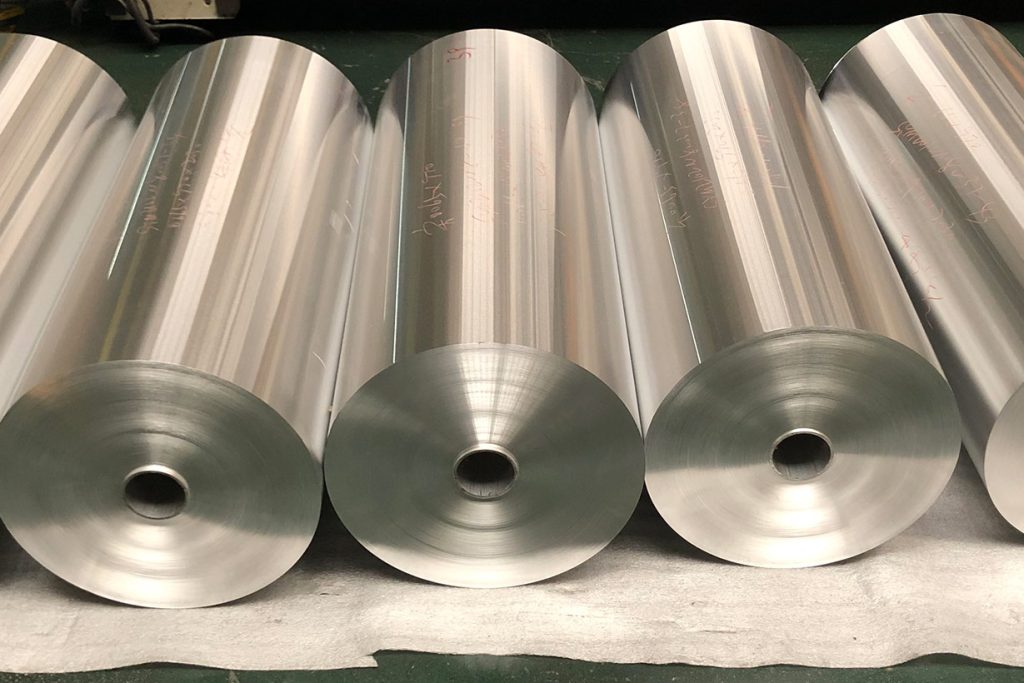

Aluminum foil, usually refers to aluminum with purity over 99.5% and thickness of less than 0.2 mm, while aluminum foil used for composite materials is thinner. Of course, different countries have different requirements for the thickness and composition of tin foil. The question is, is the thin aluminum foil capable of doing food packaging well? It also starts with the mission of food packaging and the characteristics of aluminum foil.

Although food packaging is generally not edible, but it is an important part of food commodity attributes. In terms of the function of food packaging, the core of the food protection function. Food goes through a complex process from production to consumption, and therefore may be affected by biological, chemical, physical and other external factors in the environment. Food packaging shall be able to maintain the stability of food quality and resist various adverse effects in the environment. At the same time, food packaging should also meet the requirements of beautiful, convenient, environmental protection, cheap and other aspects.

Characteristics of Aluminum foil

Let’s look at the characteristics of aluminum foil. First, it has a high mechanical strength, has a certain impact resistance and puncture ability, therefore, in the process of storage and transportation, aluminum foil packaging food is not easy to be damaged by extrusion, shock, vibration, temperature difference and other factors. Second, foil has a high barrier performance, and has a very high barrier for sunlight, high temperature, water, oxygen, microorganisms and so on. These factors are the factors that promote the deterioration of food, and blocking these factors can extend the shelf life of food. Third, foil is easy to process, low cost, can meet the packaging needs of most food products, and has a beautiful silver white and mysterious texture. Fourth, aluminum metal itself is a kind of lightweight metal, extremely thin tin foil thickness is in line with the basic requirements of light packaging, which is of great significance for reducing transportation costs. Fifth, foil is non-toxic and tasteless, easy to recycle, in line with the requirements of green environmental protection and sustainable development.

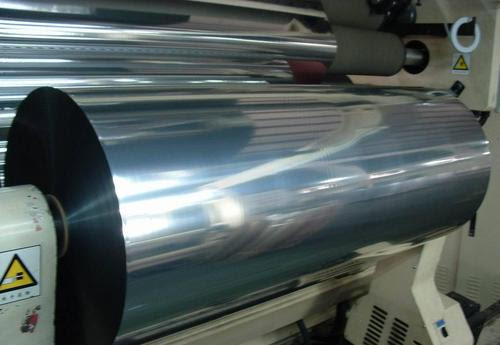

Aluminum foil has good secondary processing performance, usually can use aluminum foil and other packaging materials for composite packaging materials, so as to improve the comprehensive packaging performance of composite packaging materials.

Applicazioni

We usually call the film made of two or more materials called composite film, and the packaging bag made of composite film is called composite film bag. In general, plastic, aluminum foil, paper and other materials can be made into composite film by bonding or hot bonding methods, so as to meet the different packaging needs of a variety of food. In modern packaging, almost all the composite materials that require low light transmittance and high barrier are using tin foil as a barrier layer, because the tin foil has a highly dense metal crystal structure, which has a good barrier performance for any gas.

In the food soft packaging, there is a kind of called “vacuum coated aluminum film” packaging material, it and aluminum foil composite packaging material is not the same thing? Although both contain a very thin layer of aluminum, they are not the same material. Vacuum plated aluminized film is the high pure aluminum plated to the plastic film in vacuum state, while aluminum foil composite material combines aluminum foil with other materials by bonding or thermal bonding.

In conclusion, aluminum foil plays a crucial role in food packaging due to its versatile properties. From wrapping individual portions to sealing trays and containers, aluminum foil maintains the quality and integrity of various food products, making it an essential component in modern food packaging solutions.