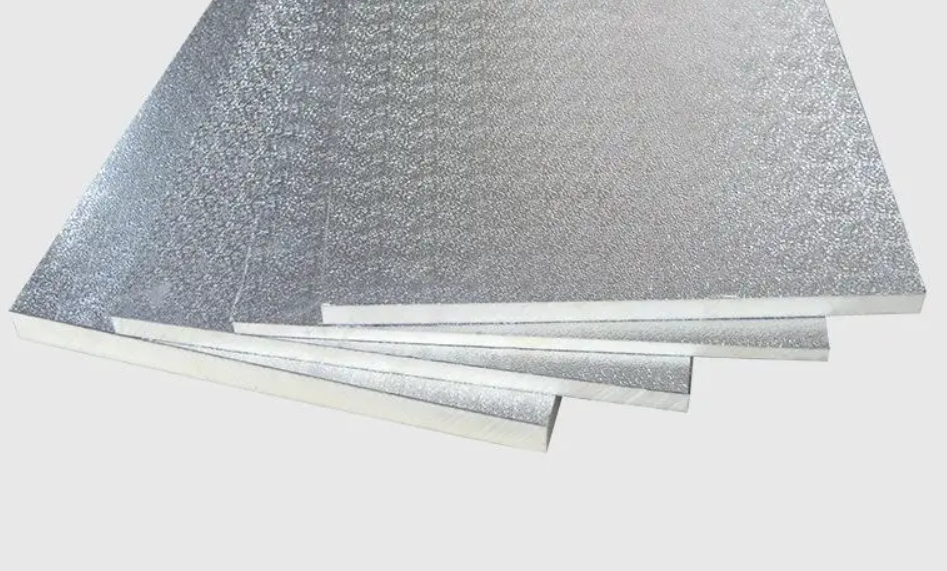

In the realm of modern construction, the demand for innovative materials that offer both efficiency and versatility has never been higher. One such material that has been gaining traction in recent years is insulated aluminum panels. These panels, comprised of aluminum layers encasing a core insulation material, boast a wide array of applications across various industries. Let’s delve into the diverse uses of these panels and their contributions to contemporary construction practices.

Building Insulation

One of the primary applications of insulated aluminum panels lies in building insulation. These panels are adept at providing thermal insulation, effectively regulating indoor temperatures and reducing energy consumption for heating and cooling purposes. Whether used in residential homes, commercial buildings, or industrial facilities, insulated aluminum panels play a crucial role in enhancing energy efficiency and occupant comfort.

HVAC Ductwork

Insulated aluminum panels are also extensively utilized in HVAC (Heating, Ventilation, and Air Conditioning) systems for ductwork insulation. Their lightweight yet robust construction makes them ideal for lining ducts, preventing heat loss or gain during the distribution of conditioned air. By minimizing thermal losses, these panels contribute to the overall efficiency of HVAC systems, leading to energy savings and improved performance.

Refrigeration and Cold Storage

In industries requiring precise temperature control, such as food storage and pharmaceuticals, insulated aluminum panels find application in refrigeration units and cold storage facilities. The excellent thermal insulation properties of these panels help maintain stable and optimal temperatures, preserving the quality and freshness of perishable goods while minimizing energy consumption.

Soundproofing and Acoustic Solutions

Beyond thermal insulation, insulated aluminum panels are also employed for soundproofing and acoustic applications. The core insulation material, often comprised of foam or mineral wool, effectively absorbs and dampens sound waves, reducing noise transmission between spaces. This makes them invaluable in environments where noise control is paramount, such as recording studios, theaters, and office partitions.

Transportation and Aerospace

In the transportation sector, particularly in automotive and aerospace industries, insulated aluminum panels are utilized for lightweight yet durable insulation solutions. Whether in automotive engine compartments, aircraft interiors, or spacecraft insulation, these panels help regulate temperatures and protect sensitive components from extreme heat or cold, all while minimizing added weight.

Packaging and Container Insulation

Insulated aluminum panels are also utilized in packaging and container insulation for temperature-sensitive products. From insulated shipping containers to packaging for perishable goods, these panels provide an effective barrier against temperature fluctuations, ensuring the integrity and freshness of the contents throughout the supply chain.

Conclusione

In conclusion, insulated aluminum panels have emerged as versatile and indispensable materials in modern construction and various industries. With their superior thermal insulation properties, lightweight construction, and durability, these panels offer solutions for energy efficiency, temperature control, soundproofing, and more. As advancements in materials science continue to drive innovation, the applications of insulated aluminum panels are expected to expand further, shaping the future of sustainable and high-performance building practices.