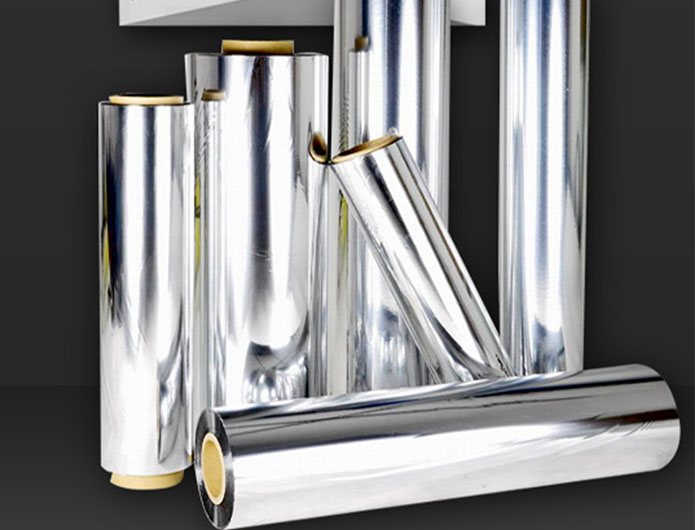

Aluminized film is a special process of extremely thin (about 300nm) plated on the surface of plastic film. Vacuum aluminum plating method is commonly used, which is melted and evaporated through the high temperature under high vacuum, so that the steam precipitation of aluminum is accumulated on the surface of the plastic film, so that the surface of the plastic film has metallic luster. At present, the most used aluminized film is mainly the polyester aluminum film (VMPET) and CPP aluminum film (VMCPP). Aluminum foil composite film is usually composed of aluminum foil and other packaging materials, there are three common structures such as: printing layer (PET, BOPP) / barrier layer (AL) / hot sealing layer (PE, CPP), etc.

The disadvantages of aluminum plating

Poor photoresistance

Light is an important factor that causes food deterioration, aluminum foil completely resist light, and aluminum plating light resistance performance is far less than aluminum foil, resulting in short food shelf life.

Aluminum plating is easy to fall off

Aluminized layer has migration and falling off, which affects food safety.

Poor corrosion resistance

Aluminization is susceptible to chemical and physical factors. Oxidation phenomenon is easy to occur in a humid environment, which affects the appearance and service life.

Water resistance and oxygen resistance are poor

The oxygen permeability and moisture permeability of aluminum plating packaging is much higher than that of aluminum foil packaging, which affects the shelf life of food.

Not resistant to high temperature

At high temperature, the aluminum plating layer will be oxidized and blackened.

Production and use defects

In the product, in the process of production and use, there are often white spots, aluminum transfer, low aluminum strength, aluminum disappearance and other problems, which affect the appearance of the bag, food shelf life and food safety.

Not to be used in water, cooking bags

Aluminized film does not have the unique braces and shading of aluminum foil, its poor water resistance, wet oxidation, desaluminization, etc., resulting in the composite open layer of composite packaging bag, so it can not be used for cooking bag series.

The way to distinguish between aluminum foil and aluminization

Watch: Because the aluminum foil is not as bright as aluminum. Aluminized bags can reflect people, but except for extinction aluminum coating, which is similar to aluminum foil. You can block the mouth of the bag, through the strong light to see the bag inside, the aluminum foil bag is not light, the light is the aluminum bag.

Feel: aluminum foil bag feel thick, crisp, hard and heavy, aluminum plated bag feels lighter and soft than aluminum foil bag.

Folding: aluminum foil bag is easy to fold out marks, aluminum bag is not easy to fold out marks and will soon bounce back.

Twist: aluminum foil bag after twist within a few seconds is not easy to rebound, aluminum bag will soon twist the kink.

Fire: the aluminum foil is not easy to burn with the fire point, the aluminum layer will roll back, after burning the aluminum foil packaging will leave gray aluminum residue. Aluminum plating bag fire can appear different plastic film combustion situation, no aluminum slag residue.