アルミニウム板は、まずアルミニウム鉱石を製錬して金属アルミニウムを取り出し、それを溶解・鋳造してスラブにし、さらに圧延・延伸などの加工を施して作られる。アルミニウム板の製造の基本は、ほとんどが冶金学と金属加工プロセスに基づいています。アルミニウム板は、軽量、高強度、熱伝導性、電気伝導性、耐食性、可塑性などの特徴的な性質を持つため、航空宇宙、自動車製造、電子機器、建築、工業分野で広く利用されています。この記事では、高品質のアルミニウム板を入手するためのいくつかのアイデアを提供します:

Know The Aluminum Plates :

アルミプレートは非常に丈夫で軽量なため、取り扱い、運搬、設置が容易です。アルミニウム金属は空気に触れると酸化バリアを形成し、錆や劣化を防ぎます。耐食性に優れているため、アルミパネルは過酷な環境や湿度の高い環境での使用に適しています。さらに、アルミニウムは熱伝導性に優れており、熱を効果的に表面に放散することができます。

Types Of Aluminum Plates

アルミニウム板は1~8シリーズに分類される。各シリーズにはそれぞれの特徴と用途があります。その中でも、1000系アルミ、3000系アルミ、5000系アルミ、6000系アルミ板がよく使われ、2000系、4000系、7000系は珍しい。また 8000シリーズ・アルミニウム is is primarily found in the form of aluminum foil sheets. We won’t go into too much detail here. Explain briefly several common aluminum alloy series:

1000 Series Aluminum Plate: With a minimum aluminum metal composition of 99%, this series is also known as the pure aluminum series. They are soft and pliable, making them excellent for deep sketching or spinning applications.

2000シリーズアルミニウム板:耐疲労性に優れたアルミニウムと銅の合金シリーズ。航空宇宙用途によく使用される。

3000 Series Aluminum Plate: Aluminum-manganese alloy series, with good formability and corrosion resistance. They are commonly used in the construction and automotive industries.

4000系アルミニウム板:アルミニウムとシリコンを主合金元素とする。強度が高く、特に高温でも一定の強度を保つことができる。溶接継手の品質と性能を確保するため、溶接時に適切な溶接プロセスと合金フィラーを使用する必要がある。

5000 Series Aluminum Plate: Aluminum-magnesium alloy series with excellent corrosion resistance and weldability. They are commonly used in marine and transportation applications.

6000シリーズアルミニウム板:マグネシウムシリコン合金シリーズで、成形性、溶接性、耐食性に優れている。建築や自動車産業でよく使用される。

7000系アルミニウム板:アルミニウムと亜鉛の合金シリーズで、価格が高く、強度と耐疲労性に優れている。航空宇宙用途やスポーツ用品用途によく使用される。

Assessing Your Specific Requirements:

A. Determine Aluminum Sheet Thickness:

Consider the intended use: Determine the intended application and mechanical load requirements to determine the appropriate plate aluminium thickness. Aluminium plates of different thicknesses are used in different fields. Thin aluminum sheet can be used for lighting fixtures, household appliances such as refrigerators or microwave ovens, elevators, and automobile decorative parts; thick aluminum plate can be used for aerospace aircraft, military supplies, ship decks, etc. Thicker aluminum plates generally provide greater strength and load-bearing capacity.

B. Deciding On Aluminum Sheet Size:

標準サイズとカスタムサイズの比較標準プレートサイズが要件を満たすか、カスタムサイズが必要かを判断します。標準サイズは入手が容易で費用対効果に優れていますが、カスタムサイズはオーダーメイドのソリューションを提供します。

Available Dimensions in the Market: Research the market to identify the range of plate dimensions available, such as length, width, and thickness options, the conventional size width and length of aluminum plates are 1050*2400mm, 1060*2400mm, 1100*2400mm, 1200*3800mm, and some ultra-wide aluminum plates such as widths above 1800mm can be customized and the length is within 8 meters. Common sizes of aluminum plates are:

- 4×8 aluminum sheet

- 1 8 aluminum sheets

- aluminum sheet 5mm

- 3 16アルミシート

- 1 16 アルミニウムシート

C.表面仕上げオプション:

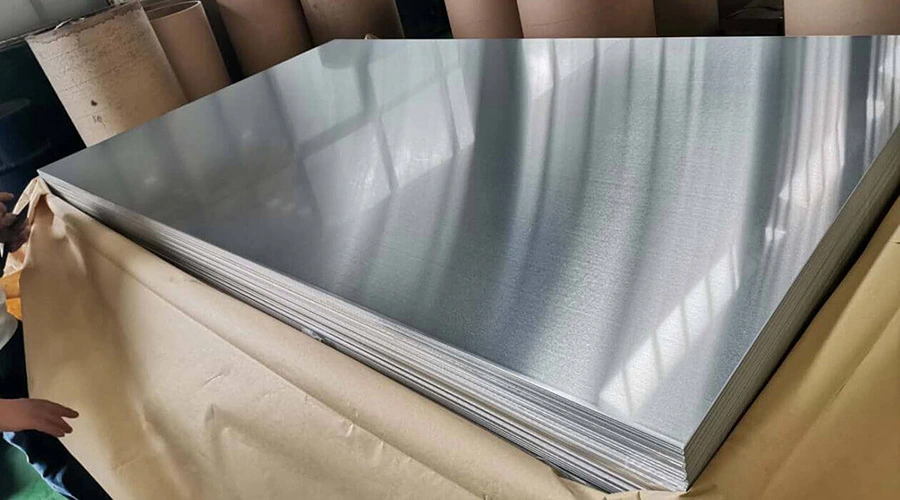

ミル仕上げ:最も基本的なオプションであるミル仕上げのプレートは、製造工程からそのままの滑らかな表面で自然な外観を持っています。

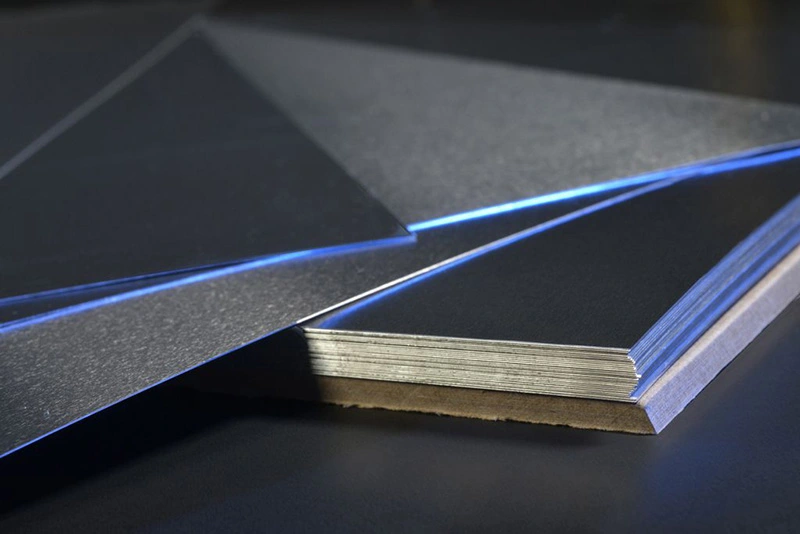

ポリッシュ仕上げ:美観を目的とした研磨仕上げは、光沢のある反射面を提供し、装飾用途によく使用される。

Anodized Finish: Anodizing alters the surface layer of the aluminum, enhancing its corrosion resistance and providing a range of color options. Anodized plates aluiminum are suitable when additional protection or a specific appearance is desired.

Selecting The Right Alloy:

Each series of aluminum alloys exhibits different properties based on its alloying elements. To determine the alloy, you must first understand the benefits and properties of each aluminum alloy series and evaluate the strength requirements, formability and corrosion resistance requirements of your application. For example, in terms of strength, the 6000 series contains strong alloying elements such as silicon, magnesium and zinc. It generally has higher strength than 5000 series aluminum alloys. It is also a widely used alloy series for industrial structural components. The 3000 series Al-Mn alloys have good corrosion resistance and weldability, and are commonly used in the manufacture of tanks, pressure vessels, and other applications. Although higher in strength than the 1000 series, they are still lower in strength compared to the 5000 and 6000 series aluminum alloys.

Assessing Aluminum Plate Quality:

アルミ板の品質を確保することは、プロジェクトの成功にとって極めて重要です。板材の品質を評価する際には、以下の点を考慮してください:

A.認証と基準:

ASTM Standards: Look for aluminum plates that comply with relevant ASTM (American Society for Testing and Materials) standards, ensuring they meet specific requirements for 機械的性質, dimensions, and tolerances.

ISO Certification: Suppliers with ISO (International Organization for Standardization) certification demonstrate adherence to internationally recognized quality management standards, providing assurance of consistent product quality.

B.材料試験と検査:

- Appearance inspection: Visually inspect the plate for any surface defects, such as scratches, dents or irregularities, and observe whether the color of the aluminum plate is consistent, whether there are spots, bubbles or color differences, etc.

- Mechanical testing: Perform mechanical tests such as tensile strength, hardness, and elongation using equipment such as tensile testing machines, durometers, etc. to verify the mechanical properties of the material.

- Weather resistance test: Expose the aluminum plate to different environmental conditions such as high temperature, low temperature, humidity, etc., and observe whether corrosion or oxidation occurs on the surface of the aluminum plate.

- Dimensional inspection: Use measuring tools to check whether the dimensional parameters such as length, width, thickness and corner roundness of the aluminum plate meet your project requirements.

Evaluating Suppliers:

A.評判の良いサプライヤーを調査する:

Check online networking platforms and industry forums for customer reviews and ratings of different suppliers, or seek advice from industry professionals or colleagues with experience working with aluminum panels to identify reliable suppliers.

B.サプライヤーの経験と専門知識:

Years in Business: Maybe you don’t understand this. There is actually no direct relationship between the number of years of establishment and the strength of the aluminum plate manufacturer. However, if the manufacturer has been in this industry for many years, then the professionalism of the aluminum plate factory must be much higher than that of a new factory.

Technical Support and Customer Service: The higher the production capacity and technical level of a supplier, the faster and more accurately it can complete the cutting work of various specifications and sizes. Good suppliers have strong enough technical strength and experience to provide customers with professional consultation and services and effectively solve any questions.

C.サンプルと仕様の要求:

Sample Availability: Requesting samples from prospective suppliers can help you understand product specifications in advance, including alloy composition, mechanical properties, dimensions and surface finish, etc.

Comparing Prices And Cost Factors:

A.サプライヤー間の価格変動:

Research the market to understand the price range for aluminum sheets, compare prices from different suppliers, and ask about the biggest discounts or special pricing suppliers can offer when ordering in large quantities or on a long-term basis. This will generally provide a price advantage for high-volume orders.

B.追加コスト要因:

There are shipping and handling costs to consider, especially when sourcing aluminum panels from international suppliers. Freight, customization, loading and unloading and other costs must be taken into account and cannot be calculated blindly.

Considering Lead Times And Availability:

プロジェクトの納期を守るためには、アルミニウム板をタイムリーに入手することが不可欠です。サプライヤーの能力と納期を以下の要素に基づいて評価してください:

A.サプライヤーの生産能力:

When choosing an aluminum plate manufacturer, you can judge whether it is strong by looking at the size of the manufacturer. The more factories, the larger the area, and generally should not be underestimated. Another most effective method is to look at the inventory of aluminum plate manufacturers. Since aluminum plate factories generally operate on spot stock, the overall strength of the aluminum plate manufacturer can be judged from the quantity of inventory in the warehouse. The larger the inventory, the higher the trust level.

B.発送および配達期間:

Consider the distance between the supplier and your location. Local suppliers usually ship quickly, while international suppliers may have longer delivery times due to customs and logistics. If you need urgent delivery, be sure to negotiate with the supplier for expedited shipping, but certain additional costs will also be incurred.

Reviewing Warranty And Return Policies:

サプライヤーの保証と返品ポリシーを理解することで、欠陥や性能の問題から確実に保護することができます。以下の要素を考慮してください:

A.サプライヤーの保証範囲:

Be sure to clarify what the supplier’s warranty covers against manufacturing defects or any performance issues that arise from the use of aluminum panels. Determine the warranty period provided by the supplier to ensure it meets your project timeline.

B.返品および交換ポリシー:

Minimize risk by familiarizing yourself with your supplier’s return eligibility criteria and procedures and inquire about any potential fees and issues associated with returning products.

Placing Your Order:

A.仕様と数量の最終決定

合金、厚さ、ゲージ、見かけの仕上げ、容積といった側面は、特に重要視されるもののひとつです。そのため、プロバイダーがこれらについて教育を受けていることを確認してください。

B.見積もりを依頼する:

Detailed Quote with Breakdown: Reach out to the supplier and request a detailed quotation that includes the individual costs of aluminum plates, any additional services or customization fees, shipping costs, and applicable taxes. This breakdown will help you understand the total cost breakdown and make informed decisions.

支払い条件:利用可能な支払い方法、入金条件、支払い期限などの支払い条件について問い合わせる。誤解を避けるため、支払いに関して不明な点は明確にする。

C.購入する:

支払い方法のオプション:銀行振込、クレジットカード、オンライン決済プラットフォームなど、サプライヤーが提供する適切な支払い方法を選択し、合意した条件に従って支払い手続きを進める。

注文確認の確認:支払いが完了したら、サプライヤーに注文確認書を請求し、注文が受領され、処理されていることを確認します。この確認書は今後の参考のために保管してください。

Taking Care Of Aluminum Plates:

A.適切な保管方法:

Store aluminum sheets in a dry environment and use protective covers or packaging to prevent corrosion and oxidation. When stacking aluminum panels, use partitions or spacers to avoid direct contact between panels and reduce the risk of scratches or damage. Handle and stack carefully to prevent dents or bends.

B.クリーニングとメンテナンスのヒント:

If there is dust buildup or corrosion on the surface of the aluminum plate, it is recommended to use a mild, non-abrasive cleaner or a special aluminum cleaner to clean the plate. When cleaning, please use a soft cloth, sponge or brush to avoid scratching the surface of the board.

よくある質問

最も安いアルミニウム板は何ですか?

Among the commonly used aluminum plate options, the most affordable option is usually aluminum alloy 3003. 3003 aluminum sheet is an aluminum-manganese alloy that is versatile and due to its wide availability and relatively low cost compared to other aluminum alloys, it Aluminum sheeting is generally considered the most economical option.

アルミニウムは安く買えるのか?

アルミニウムは一般的に、特に鉄やチタンなどの他の金属と比較した場合、安価な材料と考えられている。その主な理由は、アルミニウムが地殻に豊富に存在し、抽出コストが安く、輸送や加工が安価だからです。しかし、アルミニウムの価格は、特定の合金の種類、形状(板、スラブ、押出など)、厚さ、大きさ、市場の状況など、いくつかの要因に影響されます。具体的な回答はできません。

最も一般的なアルミニウム板は何ですか?

The most common aluminium plates are usually from 1000 series aluminum alloy or 3000 series aluminum. Aluminum 1000 series, especially alloy 1100, is known for its high corrosion resistance and good formability, making it suitable for general purposes such as cookware, signage and decorative applications, which are more common in life. 3003 aluminum among the aluminum 3000 series is popular in applications such as building exterior walls, storage tanks, and auto parts because of its economical benefits, medium strength, and excellent processing properties.