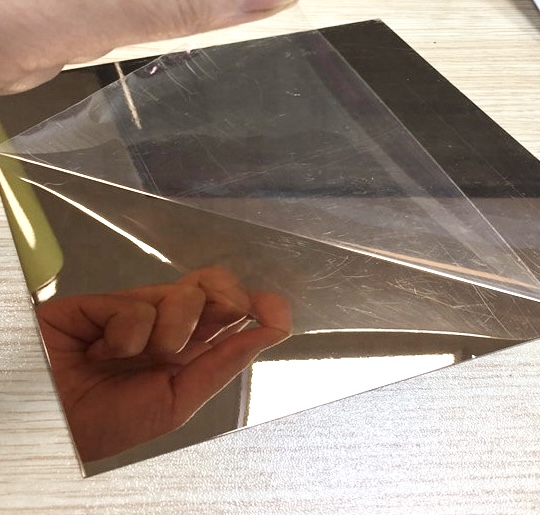

Mirror aluminum plate is a common material in aluminum plate, generally refers to the aluminum plate through rolling, grinding and other methods, so that the surface of the plate presents the mirror effect.

Material characteristics

Light weight and strong weather resistance: the use of fluorocarbon spraying and polyester paint or epoxy resin paint, can resist the strong ultraviolet radiation, protect for a long time do not change color, long service life;

Good self-cleaning, strong pollution resistance: no oil, no water, pollution prevention;

Good technology: uniform coating, diverse colors;

Rich shape: can be processed into a variety of complex shape.

Green environmental protection, this product without any harmful substances to human body;

Good adhesion, good flexibility: excellent scratch resistance enables it to resist strong impact;

グッド flatness (especially for arc and special-shaped products): the construction of the base surface requirements are low (even without leveling), with good plane stability.

Installation and construction is convenient and fast, low maintenance cost, simple maintenance;

Product type of Mirror aluminum plate

1. According to the production method:

Common film mirror aluminum plate, oxide mirror aluminum plate, polishing mirror aluminum plate and super mirror aluminum plate.

2. Surface treatment process:

Flame plating:

The first step of aluminum plate surface treatment is spraying, according to the different requirements of aluminum plate mirror appearance, the designer will use different spraying drying process. Only those aluminum plates with uniform spray surface can be used as the production of finished mirror aluminum plates.

Anti-oxidation polishing treatment:

In the actual use, some users will encounter the problem of reducing the mirror performance of the mirror aluminum plate, which is caused by the irregular surface treatment of the plate. At the same time, the mirror surface of the plate is also extremely difficult to clean. In order to meet the requirements of different properties, the surface of the mirror aluminum plate also needs to undergo special anti-oxidation polishing treatment.

Construction technology and matters needing attention

1. Production process

Install the corners according to the same horizontal height; there are different skeletons and structural accessories according to different requirements; buckle the crane and the triangle keel under the light steel keel and buckle the light steel keel into the space of the keel on the wall of the main structure according to the size of the plate, the crane of the keel must be adjusted into the bayonet into the quick seam; each plate is equipped with sealing strips; After checking the flatness, package it separately and transport it to the site for installation;

2. Construction matters needing attention

Check the parts to be installed before laying out; fix the skeleton; bounce the skeleton to the base; fix from one end; connect pipes and tie brackets; clean up work site; concealed acceptance; reinspection; cast concrete; protect curing finished products; and completion acceptance.

Apply

Mirror aluminum plate is widely used. It is widely used in lighting reflector panels, solar thermal reflective materials, interior building decoration, exterior wall decoration, household appliances panel, electronic products shell, furniture kitchen, automobile interior and exterior decoration, signs, logos, bags, jewelry boxes and other fields.