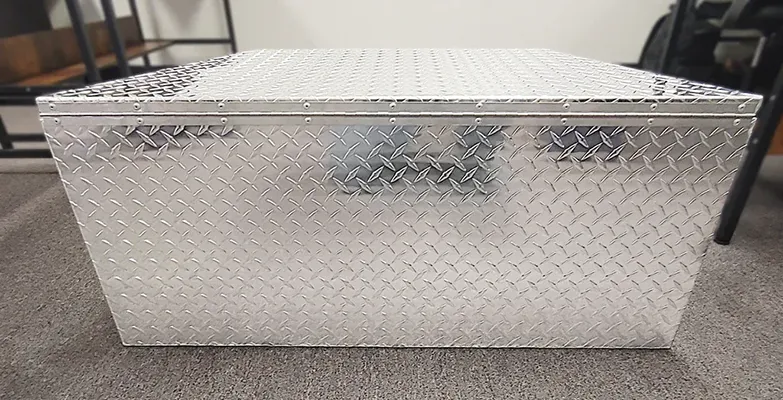

Aluminium tool box is a tool storage and protection device specially designed for use on trucks. They are usually made of different series of aluminum alloy materials and have the advantages of beautiful appearance, light weight and strong load-bearing capacity. The outer shell of this aluminum tool chest is sturdy and durable, able to withstand harsh working environments and vibrations, ensuring the safety of tools during transportation and use.

The lightweight aluminum storage boxes can be installed on pickup trucks, trailers, pump trucks, etc. to store a variety of tools such as loading and unloading tool boards, jacks, wrenches, crowbars, and even vacation and camping supplies.

Advantages of Aluminium Tool Box For Trailers:

- 高強度

- Anti-corrosion

- High quality and durable

- 軽量

- 掃除が簡単

- Strong safety performance

- Seal design

What Type Of Aluminum Are Truck Tool Boxes Made From?

Aluminium tool boxes for caravans can be made of different series of aluminum alloys, generally 1060, 1070, 3003, 5052, 6061, etc. Among them, 5052 aluminum alloy has the highest strength, and the thickness of aluminium tool boxes are generally 1.5mm-3.0mm. Smaller tool boxes will use thinner aluminum sheets, while larger tool boxes will require thicker aluminum sheets for strength and durability. Usually, the surface of the aluminium truck box is mainly made of diamond plate tool box, especially black diamond plate tool box. The main embossed form is: 3-bar aluminum checker plate or 5-bar aluminum checker plate.

1060 aluminium truck tool box: Commonly used in manufacturing light trucks such as light trucks, vans, pickup trucks, etc.

1070 aluminum truck tool box: Suitable for manufacturing truck tool boxes that require higher strength and durability, such as heavy trucks, flatbed trucks, commercial vehicles with larger loads, etc.

3003 aluminium tool box: Commonly used in the manufacture of medium-sized trucks such as medium-sized trucks, box trucks and other medium-load commercial vehicles may use 3003 aluminum alloy truck tool boxes.

5052 aluminium tool box: 5052 aluminum alloy is often used to manufacture truck tool boxes such as large trucks, trailers, professional commercial vehicles, etc.

6061 aluminium tool box: Suitable for manufacturing truck tool boxes such as heavy-duty trucks, transport vehicles, etc.

Aluminium Truck Tool Box Categories:

Crossover tool box: Typically mounted at the head of a truck bed, spanning the entire width of the truck bed. They are designed to take full advantage of the width of the truck bed without impeding the use of the truck bed. Cross-over tool boxes usually have a large capacity and are suitable for storing larger amounts of tools and equipment.

Side-mount tool box: Typically mounted on the side of the truck bed, usually between the driver and passenger doors or next to the rear wheels. Their location makes the toolbox easily accessible without having to climb into the truck bed. This type of tool box is suitable for situations where tools need to be used frequently, such as couriers or maintenance workers.

Aluminum underbody tool box: Often mounted on the bottom of a truck bed, usually on the frame of the truck bed. Aluminum underbody tool boxes provide additional storage space and are especially useful for professionals who need to store large or heavy tools, such as construction workers and mechanics. They are also accessible from both sides.

Aluminum trailer tongue box: An aluminum trailer tongue box, also known as a trailer tongue storage box or simply a tongue box, is a specialized storage container designed to be mounted on a trailer tongue. Specially used to store various tools, equipment, etc.

Trailer topsider tool box: It is suitable for the front part of the trailer and is usually used to transport and store the tools and accessories required for the trailer. They are usually smaller and suitable for trailers moving on the road.

Overhead tool box: An overhead tool box is mounted on top of the truck body, usually on the edge of the side or top of the truck body. They provide additional storage space without obstructing the use of the truck bed. These tool boxes are often used to store light tools and materials.

Considerations When Choosing An Aluminum Truck Tool Box:

- Types of Tools and Equipment: First, identify the types of tools and equipment you need to store and transport. Different aluminium tool box types and sizes are suitable for different types of tools, so make sure your tool box is large enough to accommodate your equipment.

- Truck type and size: Consider the type and size of your truck to make sure the tool box you choose will fit your truck. Different types of trucks (e.g. pickup trucks, vans, trailers) may require different types of tool boxes.

- Aluminium Tool Box Types: Learn about the different types of tool boxes, including cross-mount, side-mount, bottom-mount, trailer-mounted, and overhead tool boxes. Choose the type that suits your needs.

- Size and Capacity: Determine the size and capacity of the tool box you need. Consider the number of tools and equipment you typically need to carry to make sure your tool box is roomy enough.

- Customization options: Consider whether you want customization options inside the aluminium tool box, such as shelves, dividers, drawers, and compartments to better organize and protect your tools.

- Durability: Look at the tool box’s durability features, including materials and build quality. Aluminium tool boxes are often known for their durability, but make sure they are suitable for your use.

- Security: Focus on the security of the toolbox, including locking mechanisms and anti-theft features. A tool box should effectively protect your tools and equipment.

- Maintenance and Care: Understand the maintenance needs of your aluminium tool box. Some tool boxes may require more frequent maintenance, while others are relatively low maintenance.

- Price Range: Choose a toolbox within the appropriate price range based on your budget. The prices of toolboxes of different brands and models vary greatly.

- Brand and Manufacturer: Choose a well-known brand and reliable manufacturer to ensure tool box quality and after-sales service.

- Customer Reviews: Check out aluminium tool box reviews and feedback from other users to get a feel for real-world experience and performance.

- Appearance: Finally, you might also consider the appearance and color of your tool box to match the exterior of your truck.

What Do You Put In a Trailer Tool Box?

Trailer tool boxes are often used to store tools and equipment needed to perform specific tasks on the road or in remote areas. Here are some common items you can consider putting in your towing tool box:

Basic hand tools such as wrenches, pliers, screwdrivers, hammers, socket sets, and adjustable wrenches.

Power tools: such as a cordless drill, circular saw, angle grinder, or portable air compressor.

Safety equipment: Such as work gloves, safety glasses, ear protection, dust mask and first aid kit.

Electrical supplies: Such as electrical tape, wire cutters, wire strippers, connectors, and multimeters.

Fasteners and Hardware: Such as screws, nails, bolts, nuts, washers and other fasteners.

Lubricants and Adhesives: Includes a range of lubricants such as WD-40, silicone sprays, penetrating oils, super glue, epoxies and duct tape.

Measuring tools: such as tape measures, levels, and squares.

Spare parts: Spare parts such as fuses, belts, light bulbs and other parts that are prone to wear and tear.

Other items: Include items such as zip ties, bungee cords, a roll of tape and a small fire extinguisher.

How To Clean Aluminium Tool Box:

Cleaning an aluminum truck tool box is a relatively simple process. You’ll want to first remove all items and tools from the tool box and rinse the aluminum tool box with a hose or water source to remove loose dirt, dust, and debris. Prepare another bucket of water and mix mild dish soap or specialized aluminum cleaner with the water to create a soapy solution. Use a soft-bristled brush or sponge dipped in soapy water and gently scrub the entire surface of the tool box. When you’re done scrubbing, rinse the tool box thoroughly with clean water to remove any soap residue. Then use a clean soft cloth or towel to dry the tool box completely. These are the basic cleaning steps. If you want to restore the luster of the original aluminum, you can use a specialized aluminum polish or a high-quality metal polish and clean it slowly.