について 5083アルミニウム・ストリップ is a premium alloy renowned for its exceptional strength, outstanding corrosion resistance, and versatility in applications across a range of industries. As part of the 5000 series of aluminum alloys, 5083 is primarily composed of aluminum with significant additions of magnesium (up to 4.5%), which enhances its mechanical properties while maintaining workability. This makes 5083 aluminum strip an ideal choice for demanding environments, particularly in marine and industrial applications where reliability and endurance are crucial.

Key Features of 5083 Aluminum Strip

1. High Strength and Durability

One of the most compelling attributes of 5083 aluminum strip is its impressive strength. It boasts a high yield strength and tensile strength, making it suitable for applications that require the ability to withstand substantial loads. This characteristic is particularly valuable in structural applications, where safety and stability are paramount. The strength of 5083 ensures that it can perform reliably under various conditions, reducing the risk of failure and maintaining structural integrity.

2. Excellent Corrosion Resistance

Corrosion resistance is another standout feature of 5083 aluminum strip, particularly in marine environments where exposure to saltwater is common. The alloy’s formulation provides a protective layer that helps prevent rusting and degradation, making it an ideal choice for boat hulls, superstructures, and other maritime structures. Additionally, it is resistant to a range of other corrosive elements, including chemicals and atmospheric conditions, which broadens its application potential in industries like oil and gas and chemical manufacturing.

3. 溶接性

The weldability of 5083 aluminum strip is one of its most significant advantages. It can be easily welded using various methods, including TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) welding, which makes it a preferred choice for projects involving complex assemblies and components. Good weldability enables manufacturers to build structures with fewer joints, enhancing overall strength and durability. Furthermore, welded joints in 5083 aluminum maintain much of the alloy’s strength, ensuring the final product remains reliable.

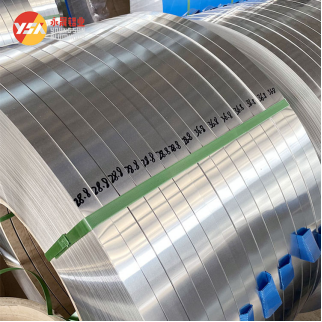

4. Formability and Fabrication

5083 aluminum strip exhibits excellent formability, allowing it to be easily shaped and manipulated into various forms such as sheets, plates, or custom profiles. This versatility makes it suitable for a wide range of manufacturing processes, from bending and machining to stamping and cutting. The material’s workability adds value during production, enabling companies to create tailored solutions for specific requirements without compromising on quality.

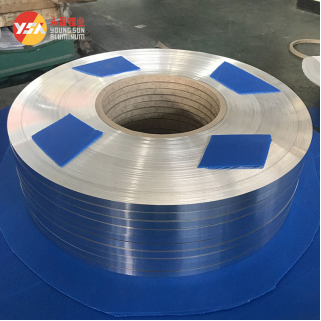

5. Surface Finish Options

The strip can be treated with various surface finishes, including anodizing, painting, and powder coating. Anodizing, in particular, enhances the aluminum’s natural resistance to corrosion while allowing for decorative effects. These treatment options not only extend the material’s lifespan but also improve its visual appeal, making 5083 aluminum strip an attractive choice for architectural applications, signage, and consumer products.

Diverse Applications of 5083 Aluminum Strip

– Marine Industry: In the marine sector, 5083 aluminum is extensively used for constructing ship hulls, superstructures, and other vital components. Its high strength and corrosion resistance make it a perfect choice for vessels that encounter harsh sea conditions, ensuring they remain safe and functional over time.

– Automotive Sector: The automotive industry values lightweight materials that can improve fuel efficiency without compromising safety. 5083 aluminum strip is often used for manufacturing various structural components, body parts, and trim elements in vehicles, contributing to overall performance and fuel savings.

– Pressure Vessels: With its robust mechanical properties and corrosion resistance, 5083 is a favored material for fabricating pressure tanks and storage containers, particularly in industries that require safe and reliable containment of gases and liquids.

– Construction and Architecture: In construction, 5083 aluminum strips find application in façades, structural frameworks, and decorative elements due to their strength, durability, and aesthetic flexibility. Architects appreciate its ability to blend functionality with modern design.

– Recreational and Consumer Products: 5083 aluminum is also utilized in manufacturing recreational products such as automotive accessories, bicycles, and even outdoor furniture, where durability and aesthetic appeal are key considerations.

結論

The 5083 aluminum strip emerges as a top-tier choice for industries in need of a material that combines strength, durability, and exceptional resistance to corrosion. Its unique attributes make it particularly suitable for demanding applications in marine, automotive, construction, and manufacturing sectors. By selecting 5083 aluminum strip for your projects, you’re opting for a reliable and versatile solution that will perform under pressure and withstand the test of time.