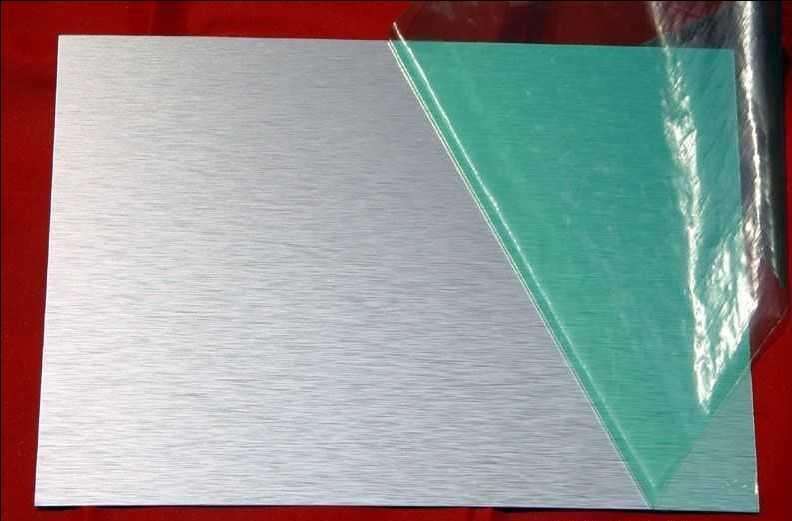

Good processability

Anodized aluminum plate has strong decorative properties, moderate hardness, and can be easily bent into shape for continuous high-speed stamping, making it convenient to directly process into products without the need for complex surface treatment, greatly reducing product production cycle and lowering production costs.

Good weather resistance

Standard thickness oxide film (3 μ m) Anodized aluminum plates do not discolor, corrode, oxidize, or rust when used indoors for a long time.

Thickened oxide film (10 μ m) The anodized aluminum plate can be used outdoors and does not change color when exposed to sunlight for a long time.

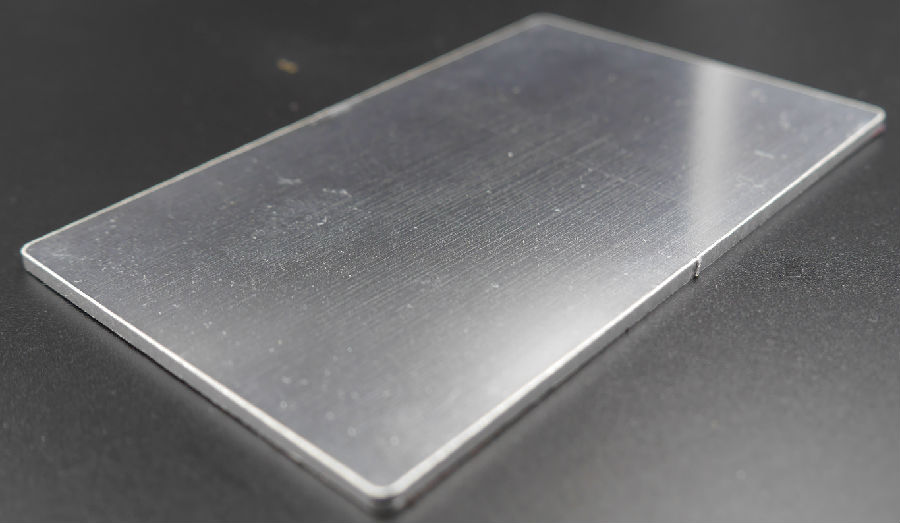

Strong metallic feeling

The anodized aluminum plate has a high surface hardness, reaching gemstone level, good scratch resistance, no paint coverage on the surface, retains the metallic color of the aluminum plate, highlights the modern metallic feeling, and improves the product grade and added value.

High fire resistance

Pure metal products, with no paint or any chemical substances on the surface, do not burn at a high temperature of 600 degrees, do not produce toxic gases, and meet fire protection and environmental protection requirements.

Strong stain resistance

No fingerprints, no stains, easy to clean, and no corrosive spots.

Strong applicability

Widely used, suitable for metal aluminum ceilings, curtain wall aluminum plates, aluminum-plastic plates, fire-resistant plates, honeycomb aluminum plates, aluminum veneers, electrical plates, cabinet plates, furniture plates, etc.