自動車用アルミシート

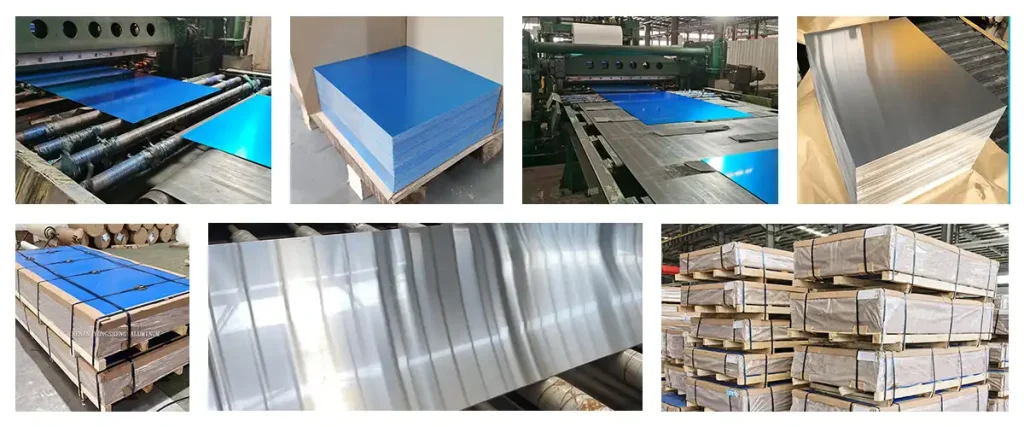

Aluminum sheet for automobile plays a significant role in the automotive industry. Aluminum sheet for automobile are primarily used in the manufacturing of vehicle body panels, such as hoods, doors, fenders, and roofs. As a leading manufacturer and supplier of premium aluminum products, Henan Yongsheng Aluminum takes great pride in our commitment to excellence. With cutting-edge technology and state-of-the-art facilities, we specialize in producing high-quality aluminum sheets, foil and coil, etc. Our dedicated team ensures superior strength, durability, and versatility in our aluminum offerings, providing customizable solutions tailored to meet specific needs.

製品紹介

Aluminum sheet for automobile also provide excellent corrosion resistance, enhancing the lifespan and durability of the vehicle. Additionally, aluminum sheet for automobile offer high formability, allowing for the production of complex shapes and designs in automobile components. The use of aluminum sheet for automobile supports the industry’s ongoing efforts towards lightweighting, sustainability, and enhanced performance.

仕様

| Alloy series | 5000 series, 6000 series |

| 合金 | 6061, 6063, 5052, 5083 |

| 厚さ(mm) | 0.1-500 or as required |

| 幅(mm) | 500mm–2000mm |

| MOQ | 1トン |

| 配送 | レディストック:7-10日、将来の商品:15-30日 |

| 価格 | EXW、FOB、CIF、CFR、CNFなど。 |

| 支払い | L/C、T/T、ウェスタンユニオンなど |

| 証明書 | ISO9001&GS&ROHS&FDA&TUV&ISO&GL&BV,etc. |

製品用途

Aluminum sheet for automobile finds extensive use for many kinds of purposes. Specifically, the 6061 and 6063 aluminum alloys are commonly used in automotive applications. The 6061 alloy excels in strength and corrosion resistance, making it suitable for automotive body panels like hoods, doors, and fenders. On the contrary, the 6063 alloy, with its good formability and extrudability, is often chosen for automotive trim, moldings, and structural components. Similarly, the 5052 and 5083 aluminum alloys are frequently utilized in automobiles. The 5052 alloy provides fantastic formability and high corrosion resistance, making it well-suited for automotive fuel tanks and body panels. At the same time, the 5083 alloy’s exceptional anti-rust characteristics in marine environments makes it a preferred choice for vehicles operating in harsh conditions, such as marine or off-road settings.

製品の利点

- A certain constancy in aging: Aging stability is the quality that prevents aluminum alloy sheets from aging when kept at room temperature. Plates frequently need to be transported and stored for a while from production to parts stamping because aging will cause the alloy to elongate at the yield point during tensile deformation, or Lude ribbon. This will cause uneven surface deformation and wrinkling during stamping, which will affect the appearance of stamping parts. Plates must typically be kept at room temperature for six months without aging.

- Good resilience to baking: After stamping, paint-cured automobile stamping parts will also age, a process known as bake hardening that increases the yield strength of the components. Parts with strong dent resistance will have high bake hardenability. Because most auto manufacturers currently design the paint baking process for steel plates, and because aluminum alloy plate baking hardenability differs significantly from steel bake hardenability.

- Good ductility at flanging: The term “flanging ductility” refers to the plate’s resistance to cracking when stamping the outside panel of a car. Thus, to guarantee that there is no cracking during flanging, an aluminum alloy plate needs to have strong flanging ductility.

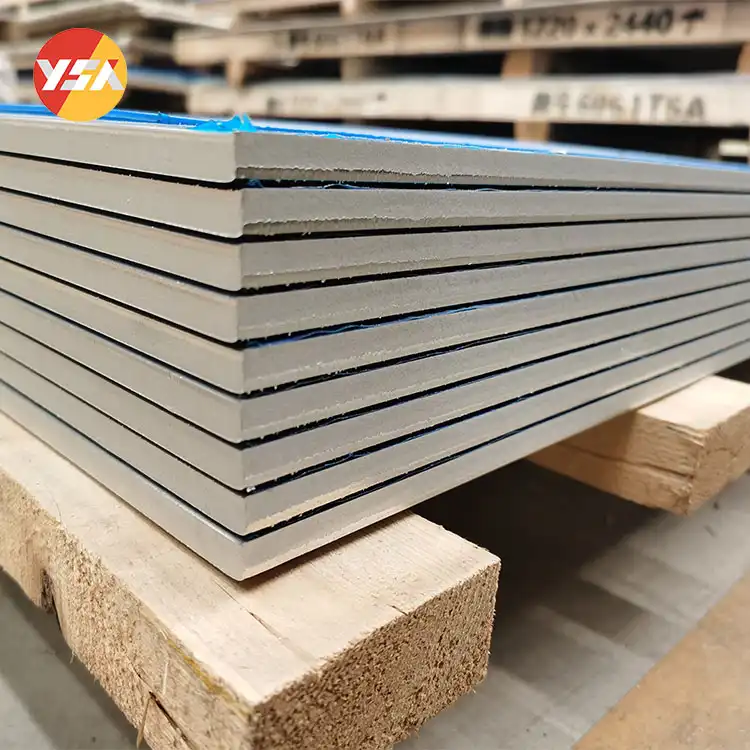

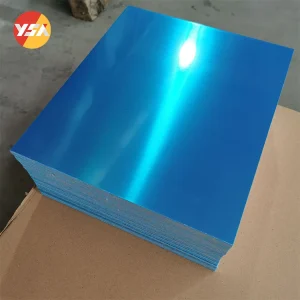

製品とパッケージの写真

私たちを選ぶ理由

Yongsheng Aluminumは25年の輸出経験を持つ中国の一流のアルミニウムプロダクトmanufacturer&supplierです。私たちの優れた製品の品質、価格、および常にオンタイムの配信は、私たちは多くの長期的なパートナーを獲得し、世界的に大きな評判を得ています。CC&DCアルミニウム製品のワンストップ製品ソリューションを提供します。

業務処理プロセス