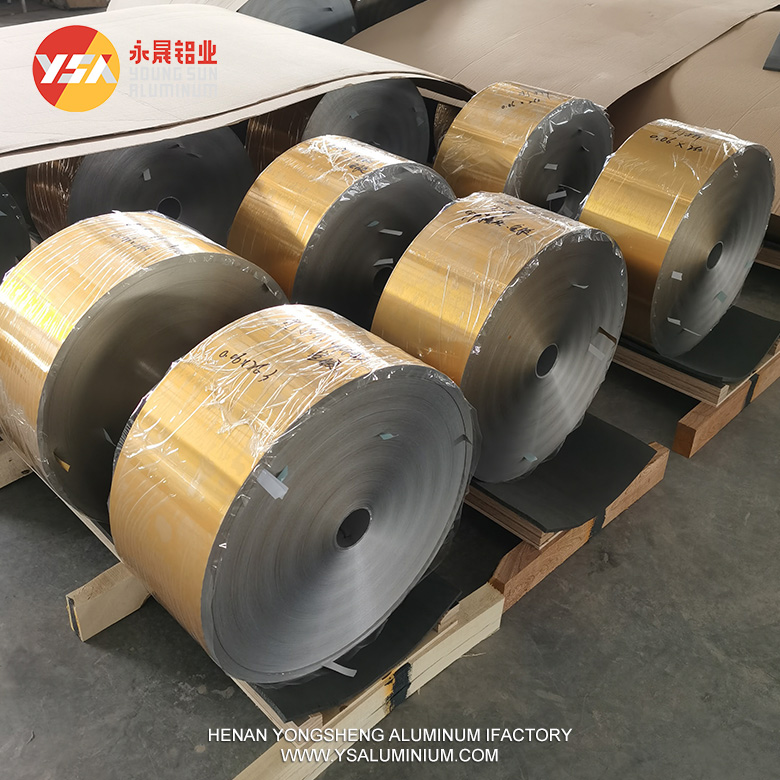

Coated aluminum foil refers to aluminum foil that has been coated with a protective or functional layer to enhance its properties and expand its range of applications. It is widely used in food packaging, construction materials, pharmaceutical packaging, and other fields due to its many advantages over uncoated aluminum foil. Here are some key benefits of coated aluminum foil:

Enhanced Corrosion Resistance

Coated aluminum foil boasts excellent corrosion resistance. The coating on the aluminum foil surface effectively prevents the penetration of moisture, oxygen, and chemicals, extending the foil’s lifespan. This is particularly beneficial in humid or corrosive environments, where coated aluminum foil significantly improves durability and prevents material failure due to corrosion.

Superior Barrier Properties

Coated aluminum foil offers outstanding barrier properties. The coating not only blocks moisture, oxygen, and ultraviolet light but also prevents the transmission of odors and light. This is especially important for food packaging, where it helps maintain freshness and original flavor, thereby extending shelf life.

Improved Mechanical Properties

Coated aluminum foil has better mechanical properties, including higher tensile strength and tear resistance. The coating increases the toughness of the aluminum foil, making it less prone to damage during processing, transportation, and use. Additionally, the coating provides better surface hardness and wear resistance, reducing scratches and wear.

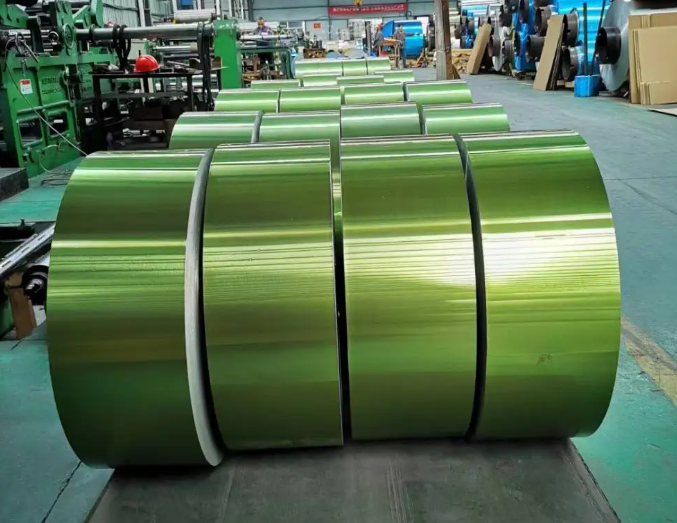

Enhanced Aesthetic Appeal and Design Flexibility

The surface of coated aluminum foil can be coated with various colors and patterns, enhancing its aesthetic appeal and decorative effect. This gives coated aluminum foil greater design flexibility in packaging and construction materials. Different colors and patterns can meet diverse market and customer needs, increasing product competitiveness.

Increased Heat Resistance and Flame Retardancy

Certain specific coatings can significantly enhance the heat resistance and flame retardancy of aluminum foil. Coated aluminum foil does not easily deform or degrade in high-temperature environments, making it suitable for applications requiring high-temperature resistance, such as oven use. Additionally, flame-retardant coated aluminum foil can improve fire safety when used in construction materials.

Excellent Processing Performance

Coated aluminum foil offers excellent workability during processing. The coating can reduce friction and adhesion issues during cutting, folding, and stamping, improving processing efficiency and product quality. Moreover, the coating can reduce waste and loss during processing, lowering production costs.

結論

Coated aluminum foil, with its enhanced corrosion resistance, superior barrier properties, improved mechanical properties, enhanced aesthetic appeal and design flexibility, increased heat resistance and flame retardancy, and excellent processing performance, demonstrates significant advantages in various application fields. Whether in food packaging, construction materials, or pharmaceutical packaging, coated aluminum foil brings great convenience and benefits to modern industry and daily life with its outstanding performance and diverse applications.