No matter what product goes through some processes before leaving the factory, it ultimately presents itself in a perfect state before the eyes of consumers. Of course, aluminum plates are no exception. Today, let’s explore the transformation path of aluminum plates together!

Cutting materials

Cutting refers to the process of removing materials of a certain shape, quantity, or quality from the entire or entire batch of materials after determining the required material shape, quantity, or quality for the production of a certain equipment or product. Aluminum plate cutting refers to cutting an entire aluminum plate according to the requirements of the production department’s processing drawings. As cutting is a mechanized operation, there is no need to worry about uneven cutting or missing edges. After the production department’s drawings are confirmed, the cutting can be carried out.

Bending

Under the pressure of the upper or lower mold of the bending machine, the metal sheet first undergoes elastic deformation, and then enters plastic deformation. At the beginning stage of plastic bending, the sheet is free to bend. As the upper or lower mold applies pressure to the sheet, the inner surface of the V-shaped groove between the sheet and the lower mold gradually becomes closer, and the curvature radius and bending force arm gradually decrease. Continue to apply pressure until the stroke ends, so that the upper and lower molds are in full contact with the sheet at three points. At this point, a V-shaped bending is completed, which is commonly known as bending. Bending generally starts with the short side and then the long side. During the construction process, the processing sequence should be adjusted appropriately according to the shape of the bending or obstacles on the workpiece. The bending process causes plastic deformation of the aluminum plate, making it more convenient for the installation and disassembly of the aluminum plate.

Welding

Welding, also known as fusion welding, is a manufacturing process and technique that involves joining metals or other thermoplastic materials such as plastics through heating, high temperature, or high pressure. The main purpose of welding is to connect small metal materials into larger ones according to the drawings or required dimensions, or to create the required geometry through welding. To a certain extent, welding can make the shape of aluminum plates diverse.

Polishing

Generally speaking, the methods of polishing and polishing can be divided into the following: first, use polishing and polishing discs to polish and polish; Secondly, use a knife or rough sandpaper to polish and polish; Thirdly, water sandpaper polishing is commonly used in the polishing process of aluminum plates using the first method. The polishing process ensures that the surface of the aluminum plate has no obvious marks, scratches, or tooth marks, and the overall surface presents a clean, smooth, and flat state.

Spray coating

Spray coating refers to the coating method that uses a spray gun or disc atomizer, with the help of pressure or centrifugal force, to disperse into uniform and fine mist droplets, and apply them to the surface of the coated object. Due to the large production quantity, the use of fully automatic spraying not only reduces the harm of powder to manual labor, but also improves efficiency.

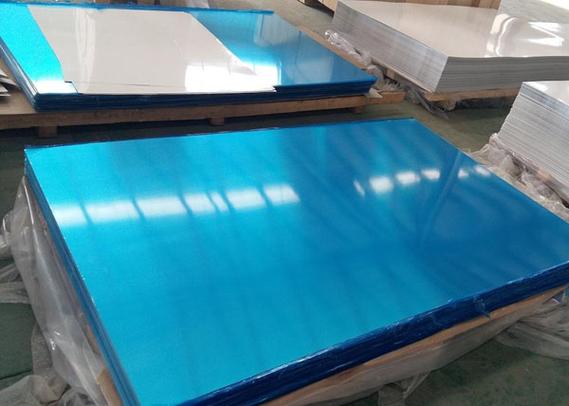

Film covering

The newly produced aluminum plate has a bright color and a smooth surface. If it is directly packaged and installed during transportation, it may cause slight damage to the surface of the aluminum plate due to bumps and other reasons. To avoid this situation, the aluminum plate is usually coated with film before shipment, which provides good protection for the aluminum plate.