The drawing treatment of aluminum sheet is done after stamping, and the drawing process generally includes mechanical drawing, chemical drawing, electrochemical drawing, etc. According to decoration needs, it can be made into several types such as straight lines, irregular lines, threads, ripples, and spiral lines. The processing steps of brushed aluminum sheet mainly include four steps: aluminum sheet drawing, sheet metal processing, water washing and degreasing, and surface painting.

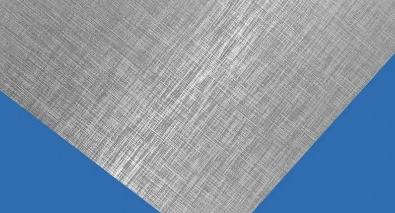

Linear drawing

It refers to the process of machining straight lines on the surface of aluminum plates using mechanical friction. It has the dual function of brushing away scratches on the surface of the aluminum plate and decorating the surface of the aluminum plate. Among them, straight drawing has two methods: continuous drawing and intermittent drawing.

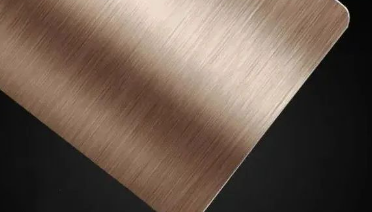

Random pattern drawing

Under the high-speed operation of the copper wire brush, the aluminum plate is moved back and forth, left and right, and rubbed to obtain an irregular and indistinct matte line pattern. This type of processing requires a higher surface quality of the aluminum plate.

Corrugated wire drawing

It is usually done on a brushing or polishing machine. Utilize the axial movement of the upper group of grinding rollers to grind and brush the surface of the aluminum plate, forming wavy patterns.

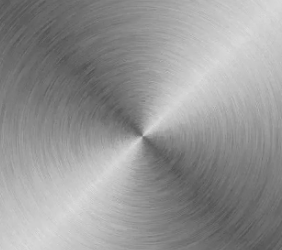

Spiral drawing of brushed aluminum sheet

A type of silk pattern obtained by using cylindrical felt or grinding stone nylon wheels mounted on a drilling machine, and rotating polishing with kerosene and polishing paste to polish the surface of aluminum plates. It is mostly used for decorative processing of circular signs and small decorative dials.

Thread drawing

Fix the small motor with a circular felt on the shaft on the workbench at an angle of about 60 degrees to the edge of the workbench. Use another drag plate with a fixed aluminum plate, and stick a polyester film with a straight edge on the drag plate to limit thread competition. Utilize the rotation of the felt and the linear movement of the drag plate to create a thread pattern with a consistent width on the surface of the aluminum plate.

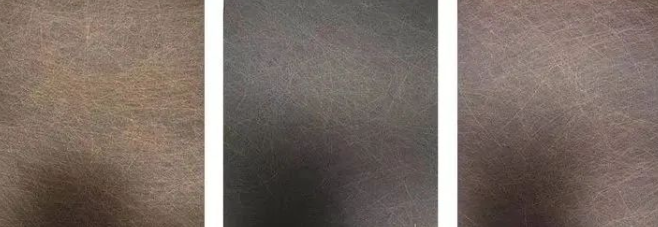

Cross pattern drawing

It is generally processed on a brushing or polishing machine, and the aluminum plate passes through two sets of rollers to create a cross pattern on the surface of the aluminum plate.